Method for manufacturing TiAl intermetallic compound through heterogeneous double-wire TOP-TIG electric arc additive manufacturing

A TOP-TIG, intermetallic compound technology, applied in the field of additive manufacturing, can solve the problems of large difference in melting characteristics of titanium alloy welding wire and aluminum welding wire, uneven composition of intermetallic compounds, etc. Out of sync, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

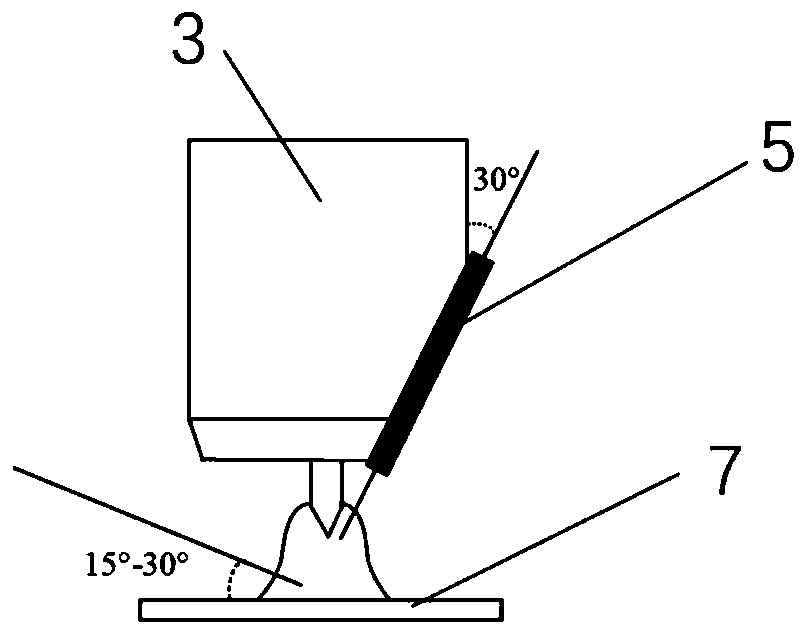

[0031] Such as figure 1 As shown, the method of this embodiment uses the TOP-TIG welding torch 3 integrated with the second wire feeder 4 to complete additive manufacturing, and also includes the first wire feeder 1 . The design size of the wall component in this embodiment is: 130mm×10mm×30mm, the titanium alloy welding wire used is Ti6Al4V with a diameter of 1.2mm, and the aluminum welding wire is ER1100 with a diameter of 1.2mm. The specific additive manufacturing steps of TiAl intermetallic compound are as follows:

[0032] (1) Select a pure titanium plate as the substrate 7, place the substrate 7 on the heating plate 8, determine the walking path of the TOP-TIG welding torch 3 according to the shape of the required intermetallic compound member, and select a suitable deposition starting point, turn on the heating plate The power supply of 8 preheats the substrate 7, and the temperature of the substrate 7 reaches 450°C and then keeps warm;

[0033] (2) Taking the walking...

specific Embodiment approach 2

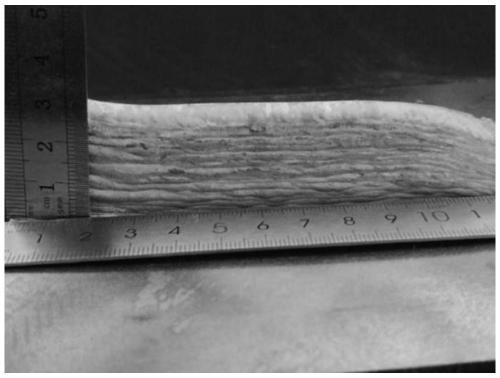

[0038] The difference between this specific embodiment and specific embodiment 1 is: the wire feeding speed of the first wire feeder 1 is 800mm / min; All are the same as in Embodiment 1. The TiAl intermetallic compound wall member that this specific embodiment obtains, as Figure 5 As shown, the wall components are intact and without cracks.

specific Embodiment approach 3

[0040] The difference between this specific embodiment and specific embodiment 1 is: the wire feeding speed of the first wire feeder 1 is 800mm / min; All are the same as in Embodiment 1. The TiAl intermetallic compound wall member that this specific embodiment obtains, as Figure 6 As shown, the wall components are intact and without cracks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com