Preparation method of BN quantum dot combined photocatalytic composite fiber

A composite fiber and photocatalytic technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, nano optics, etc., can solve the problems of weak combination and few active sites, so as to improve the efficiency of photocatalytic reaction and suppress loading. The effects of jet recombination and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

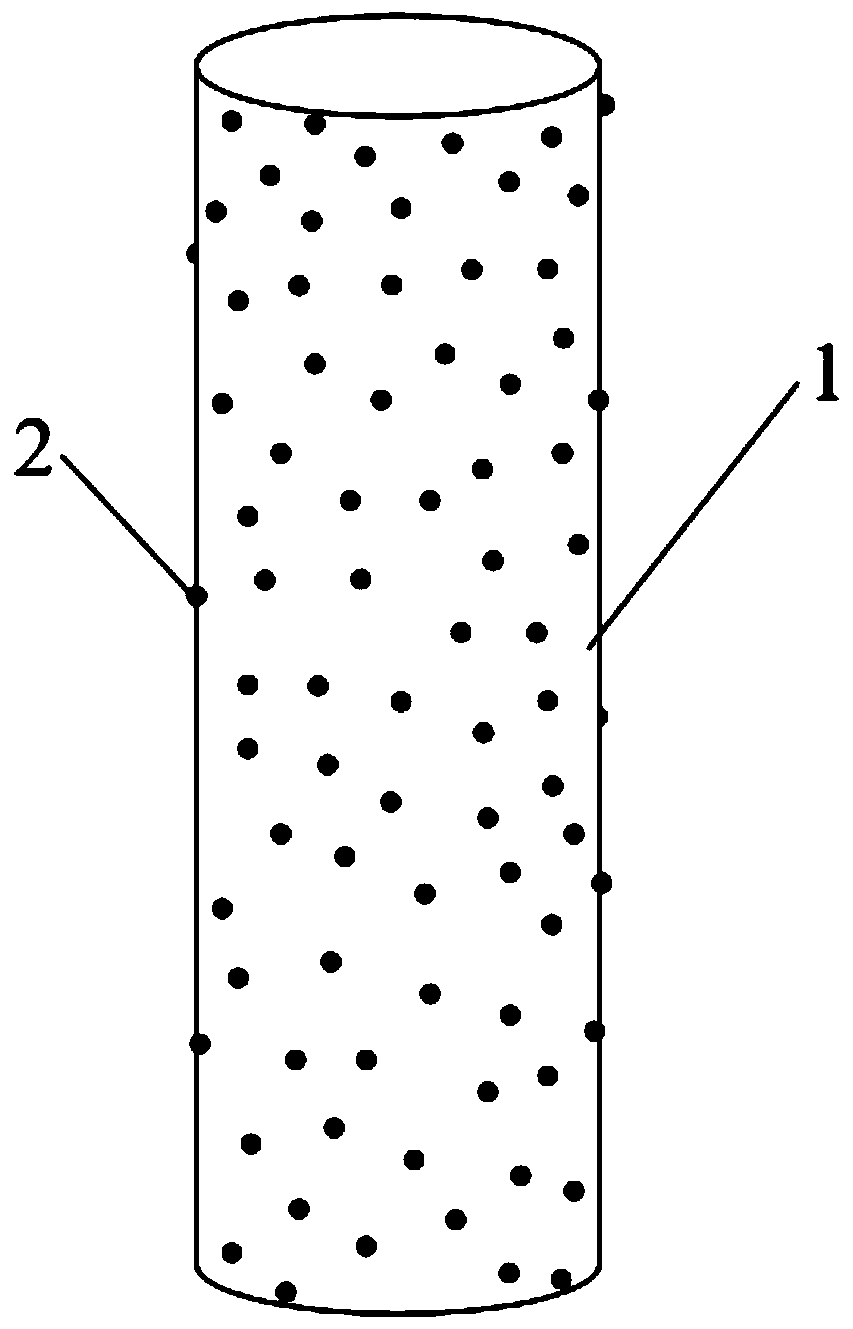

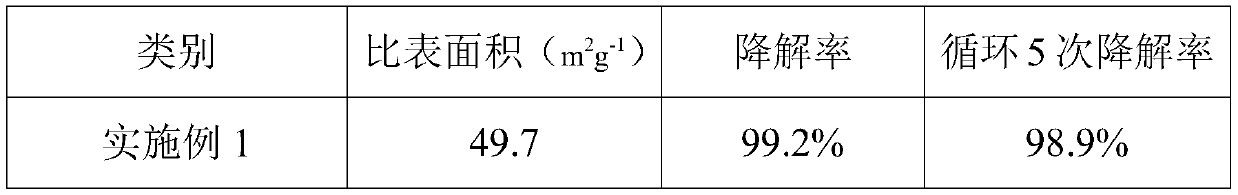

[0053] Preparation of BN quantum dot-bound TiO2 composite fiber

[0054] Put 3.5g of isopropyl titanate, 1g of PVP, 6g of DMF and 2g of glacial acetic acid into the propulsion pump, adjust the spinning voltage to 18kv, the receiving distance to 18cm, and the spinning temperature to 30°C. The humidity is 10%, the propulsion pump propulsion speed is 0.3mL / h, electrospinning is carried out, and then calcined at 550°C for 2h to obtain TiO2 nanofibers;

[0055] TiO2 nanofibers were immersed in deionized water (concentration of 1mol / L) dissolved with sodium nitrate, and irradiated with a UV lamp with a power of 300W and a light emission wavelength of 290nm for 1h to obtain modified TiO2fibers;

[0056] The modified TiO2 fibers are subjected to hydrothermal treatment: take 0.17g melamine and 0.5g boric acid and add them to 40g deionized water, stir them evenly and then move them to the reactor. The volume of the solution is 80% of the volume of the reactor. Put the modified TiO2 fibe...

Embodiment 2

[0059] Preparation of BN quantum dot-bound TiO2 composite fiber

[0060] Put 1.35g of butyl titanate, 0.9g of PVP, 12.52g of ethanol and 0.23g of acetic acid into the propulsion pump, adjust the spinning voltage to 16kv, the receiving distance to 16cm, and the spinning temperature to 30°C , the humidity is 10%, the propelling speed of the propulsion pump is 0.6mL / h, electrospinning is carried out, and then calcined at 500°C for 2h to obtain TiO2 nanofibers;

[0061] Dip the TiO2 nanofibers into deionized water (concentration of 1mol / L) dissolved with ammonium nitrate, and irradiate with a UV lamp with a power of 300W and a light emission wavelength of 390nm for 2h to obtain modified TiO2fibers;

[0062] The modified TiO2 fibers are subjected to hydrothermal treatment: take 0.136g melamine and 0.4g boric acid and add them to 40g deionized water, stir them evenly and then move them to the reactor. The volume of the solution is 80% of the volume of the reactor. Put the modified T...

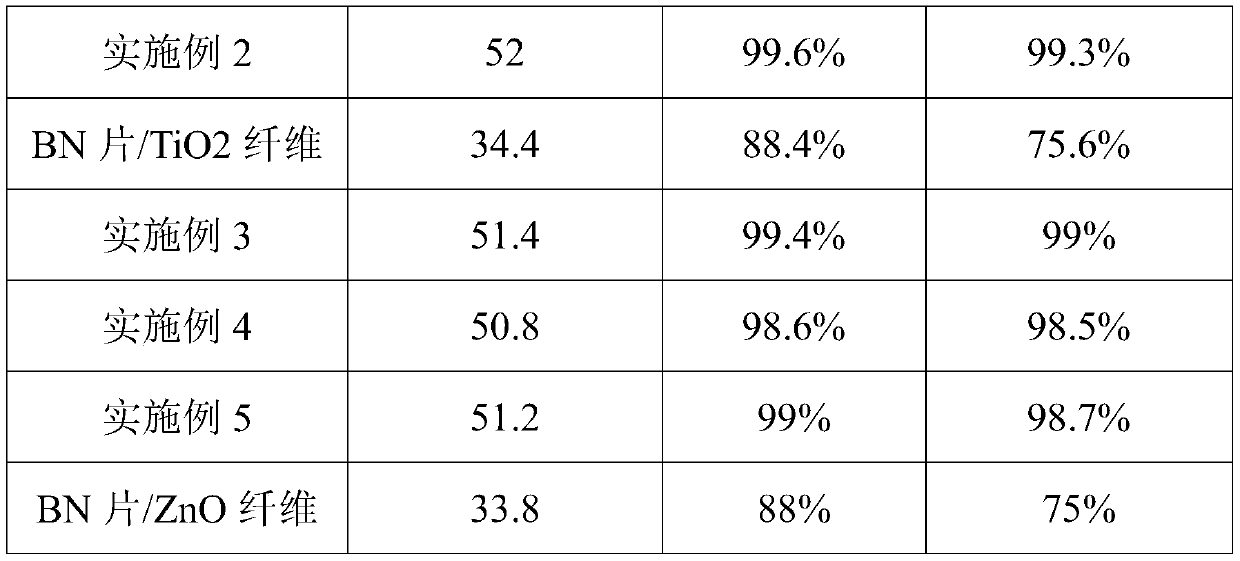

Embodiment 3

[0065] Preparation of BN Quantum Dot-Combined ZnO Composite Fibers

[0066] Mix 0.98g of PVA and 8.94g of deionized water in a 90°C water bath, then add 2.52g of zinc acetate and 1.56g of acetic acid, mix to form a uniform spinning solution and put it into the propulsion pump, adjust the spinning voltage to 18kv, and the receiving distance 15cm, the spinning temperature is 30°C, the humidity is 10%, the propulsion pump propulsion speed is 0.4mL / h, electrospinning is carried out, and then calcined at 600°C for 2 hours to obtain ZnO fibers;

[0067] Immerse the ZnO fiber in deionized water (concentration: 1mol / L) dissolved with sodium nitrate, and irradiate it with a UV lamp with a power of 500W and a light emission wavelength of 290nm for 0.5h to obtain a modified ZnO fiber;

[0068] Hydrothermal treatment of the modified ZnO fiber: Take 0.136g melamine and 0.4g boric acid and add it to 40g deionized water, stir evenly and move it to the reactor. The volume of the solution is 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com