Strong fragrant peanut oil and preparation method thereof

A technology of peanut oil and strong aroma, which is applied in the direction of fat oil/fat refining, fat production, edible oil/fat, etc. It can solve the problems of complicated process and insufficient overall flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

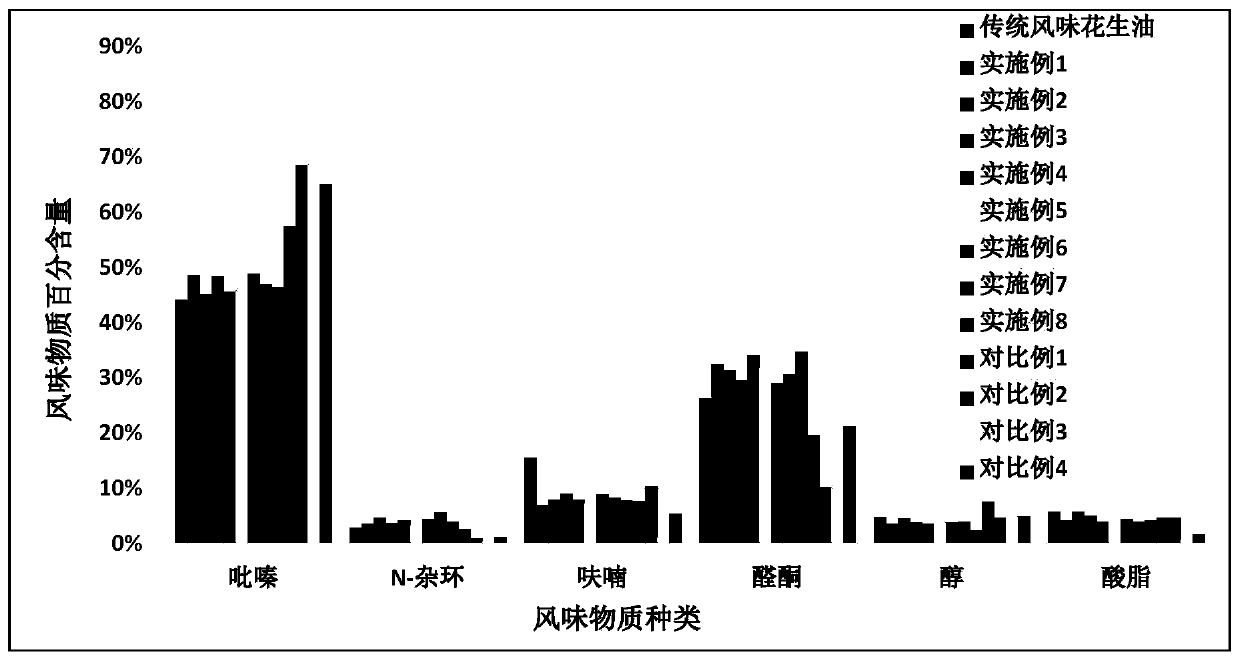

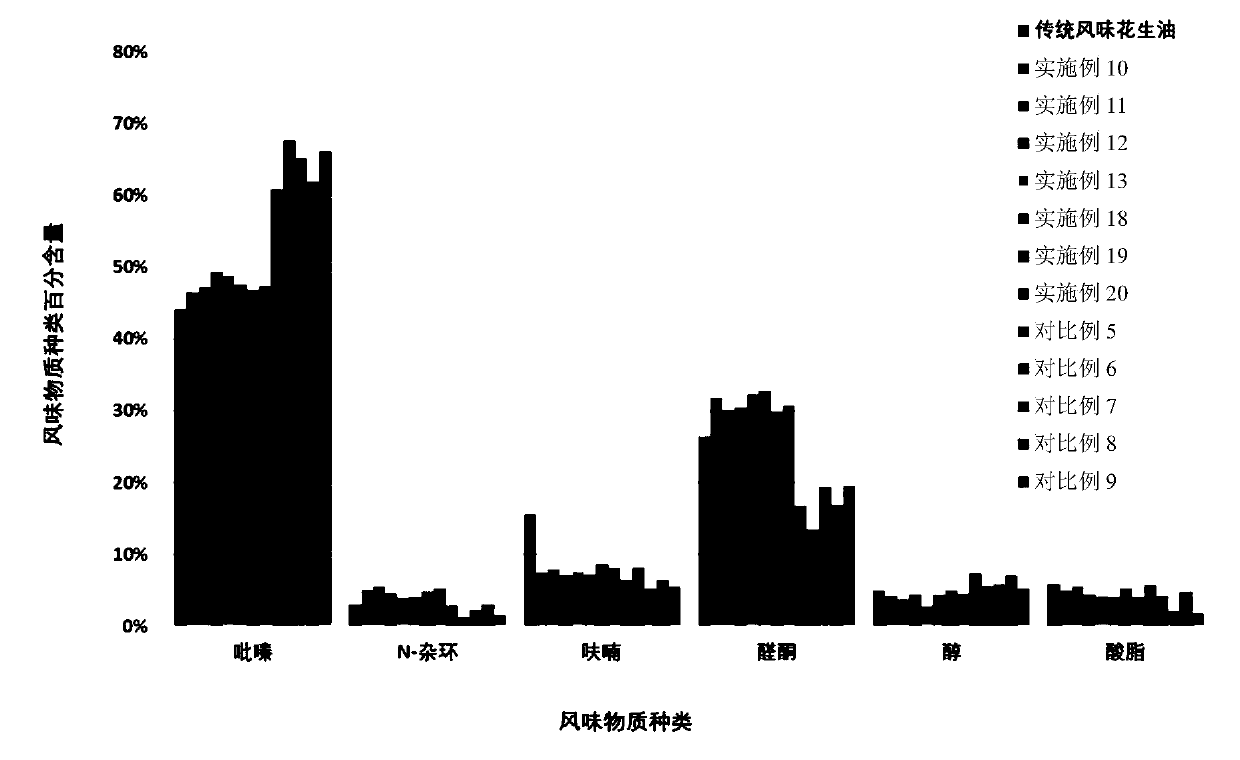

Examples

preparation example Construction

[0160] In a preferred embodiment, the preparation method of Luzhou-flavor peanut oil of the present invention comprises the following steps:

[0161] (a) Raw material pretreatment: add 3-8 times the mass of water to the undefatted peanut powder, heat to 40-60°C, and adjust the pH to 8-9 with phosphate buffer;

[0162] (b) enzymatic hydrolysis: adding 1-10% of the weight of the peanut raw material to the mixture obtained in step (a) to carry out the enzymatic hydrolysis reaction, after the reaction is completed, the enzyme is inactivated to obtain the enzymatic hydrolysis solution;

[0163] (c) drying: heating the enzymolysis solution obtained in step (b) to 40-60°C, and then spray drying;

[0164] (d) preparing the Maillard reaction system containing the dried enzymatic hydrolyzate obtained in step (c) and peanut oil: making the dry enzymatic hydrolyzate contact with peanut oil and optional water to obtain the Maillard reaction system; the Maillard reaction The water content ...

Embodiment 1

[0200] (1) Take 60g of non-defatted peanut powder, add 240g of tap water, heat to 50°C with stirring, and adjust the pH to 8.5;

[0201] (2) Add 0.5% alkaline protease, adjust the pH to 8.5 with sodium hydroxide every hour, adjust the pH to 6.0 after reacting at 50°C for 8 hours;

[0202] (3) Add 1% liquid flavor protease, 0.6% medium-temperature amylase, 1% compound glucoamylase, and 1% pectinase, and react at 50°C; adjust the pH to 6.0 with hydrochloric acid solution every hour, and adjust the pH after 8 hours of reaction to 7.8;

[0203] (4) Heat the peanut pulp after enzymolysis to 50°C, stir it mechanically, and dry it in a spray drying tower (GeaNiro spray dryer, model Mobile Minortm, the same below); set the inlet heating temperature to 180°C, and the flow rate of the atomizer to 4m 3 / h, the feed rate is 50ml / min, so that the outlet temperature is between 90°C±1°C; the water content after spray drying is <5wt%; collect the spray-dried powder and wait for the Maillard ...

Embodiment 2

[0207] (1) Take 60g of non-defatted peanut powder, add 240g of tap water, heat to 50°C with stirring, and adjust the pH to 8.5;

[0208] (2) Add 0.5% alkaline protease, adjust the pH to 8.5 with sodium hydroxide every hour, adjust the pH to 6.0 after reacting at 50°C for 8 hours;

[0209] (3) Add 1% liquid flavor protease, 0.6% medium-temperature amylase, 1% compound glucoamylase, and 1% pectinase, and react at 50°C; adjust the pH to 6.0 with hydrochloric acid solution every hour, and adjust the pH after 8 hours of reaction to 7.8;

[0210] (4) spray-drying the enzymatic solution (spray-drying conditions are the same as in Example 1);

[0211] (5) Take 30g of spray-dried powder, add 6g of water, add 210g of refined peanut oil, stir evenly, put it into a high-temperature and high-pressure reactor, and react at 170°C for 45min;

[0212] (6) After cooling, separate the oil phase to obtain Luzhou-flavored peanut oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com