Novel anti-cracking tundish water inlet and preparation method thereof

An anti-explosion and new technology, applied in the field of metallurgical refractory materials, can solve the problems of tundish nozzle burst and product loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

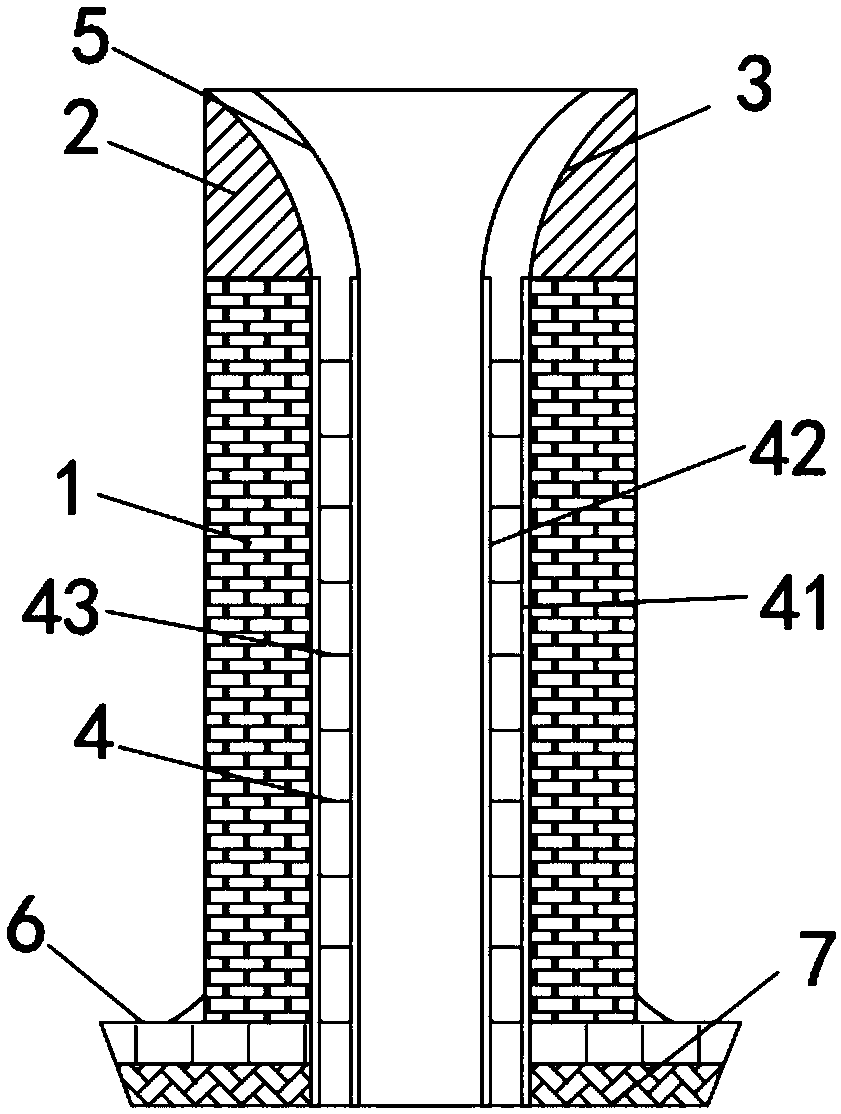

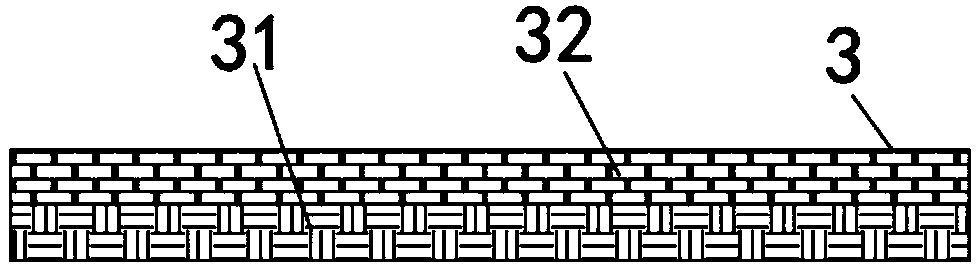

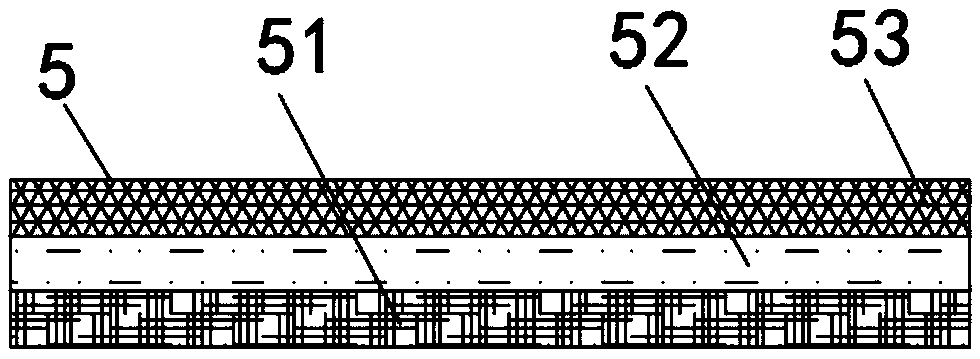

[0022] refer to Figure 1-3 , a novel anti-explosion tundish upper nozzle and a preparation method thereof, comprising an outer wall 1, the upper end of the outer wall 1 is fixedly connected with a bowl mouth 2, the bowl mouth 2 and the side walls of the outer wall 1 are provided with a first protective layer 3, the second A protective layer 3 includes a tantalum hafnium carbide coating 31 respectively arranged on the bowl mouth 2 and the side wall of the outer wall 1, wherein the tantalum hafnium carbide coating 31 is actually made of a tantalum hafnium carbide alloy, which actually refers to tetratantalum hafnium pentacarbide compound, It is the substance with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com