Container-free ultramicro chemical reaction observation device

An observation device and a technology for chemical reactions, which are applied in the field of container-less ultra-micro chemical reaction observation devices, can solve the problems that expensive reagents cannot be used in experimental teaching, do not conform to green chemistry, and have been widely promoted, so as to facilitate popularization, save experimental costs, Guarantee the effect of the experimental effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

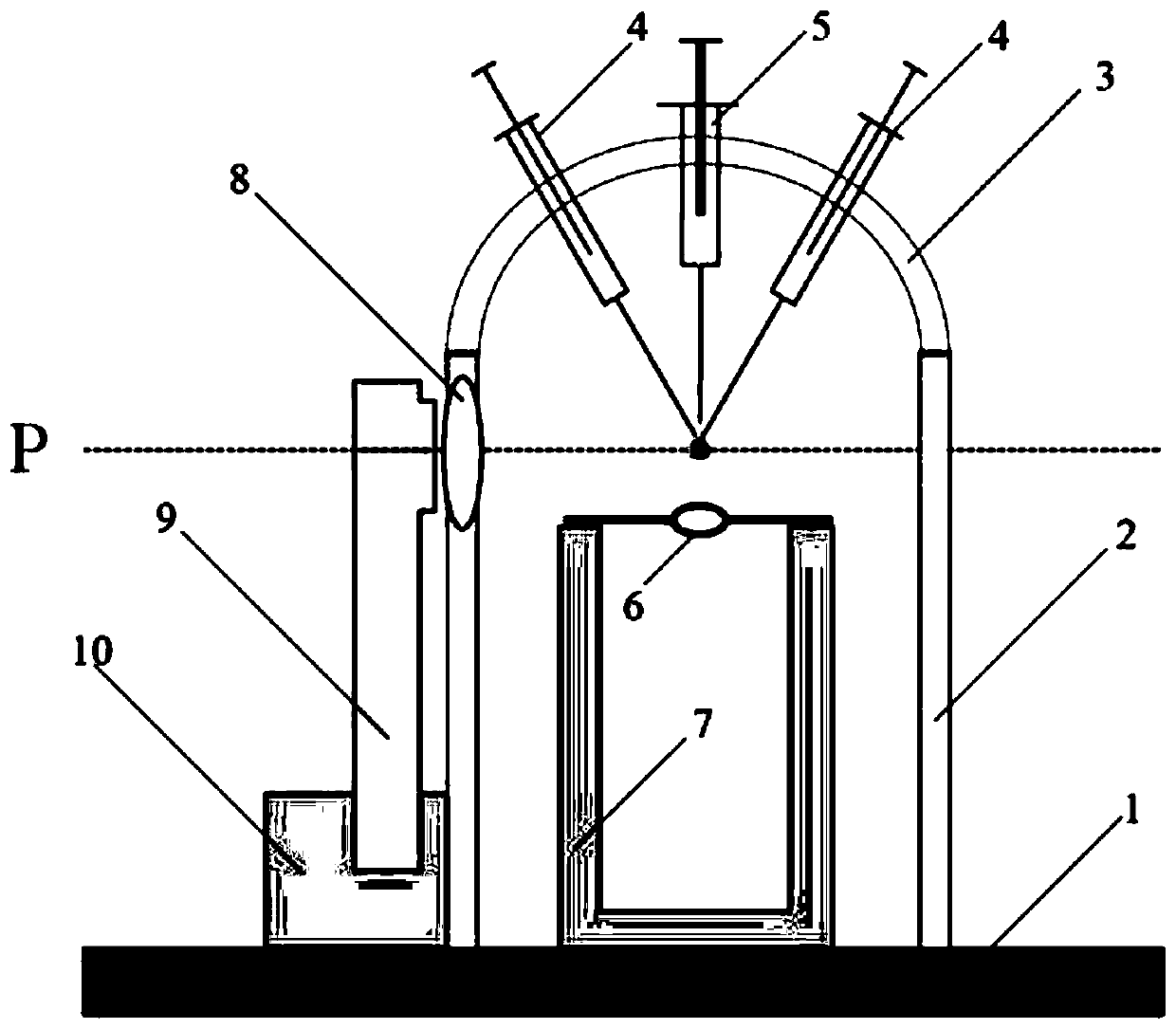

[0034] A container-less ultra-trace chemical reaction observation device, such as figure 1 As shown, it consists of a base (1), a protective cover (2), a protective cover top cover (3), a reagent adder (4), a cleaner (5), a heating coil (6), a waste liquid collector (7), A magnifying glass (8), a video acquisition device (9), and a clamp (10) are composed, and press figure 1 way to install.

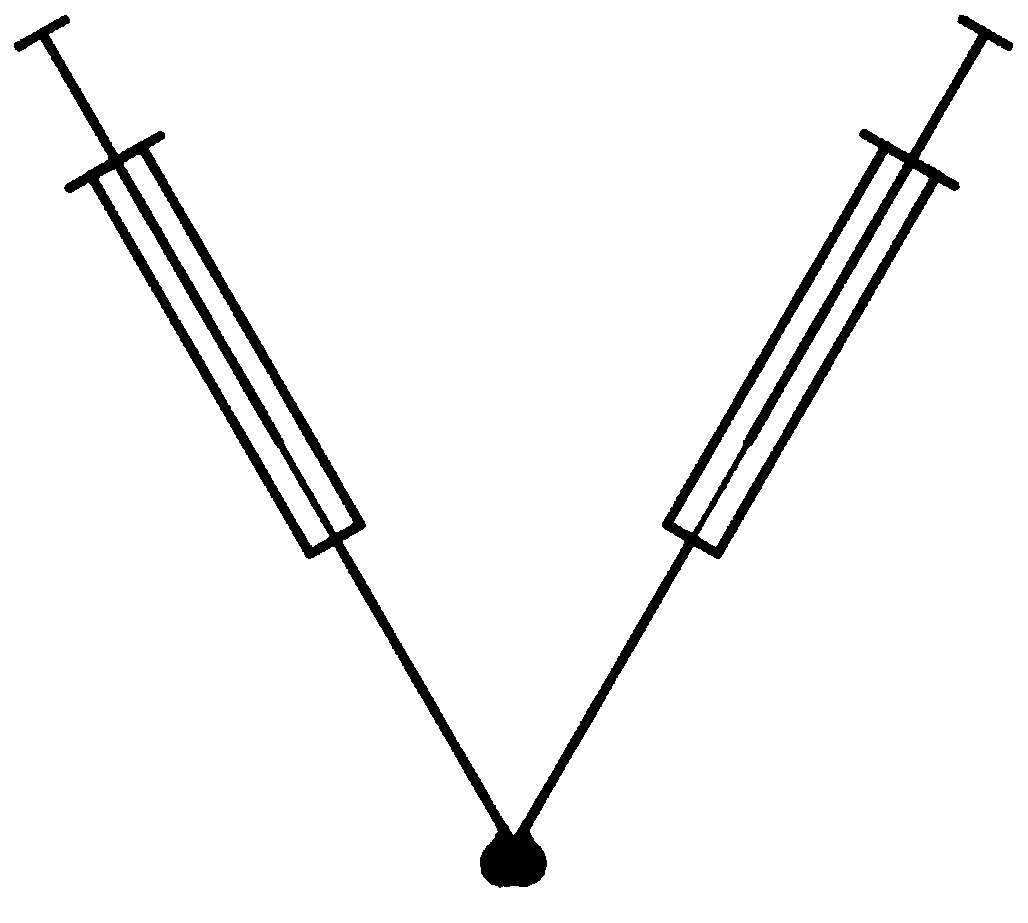

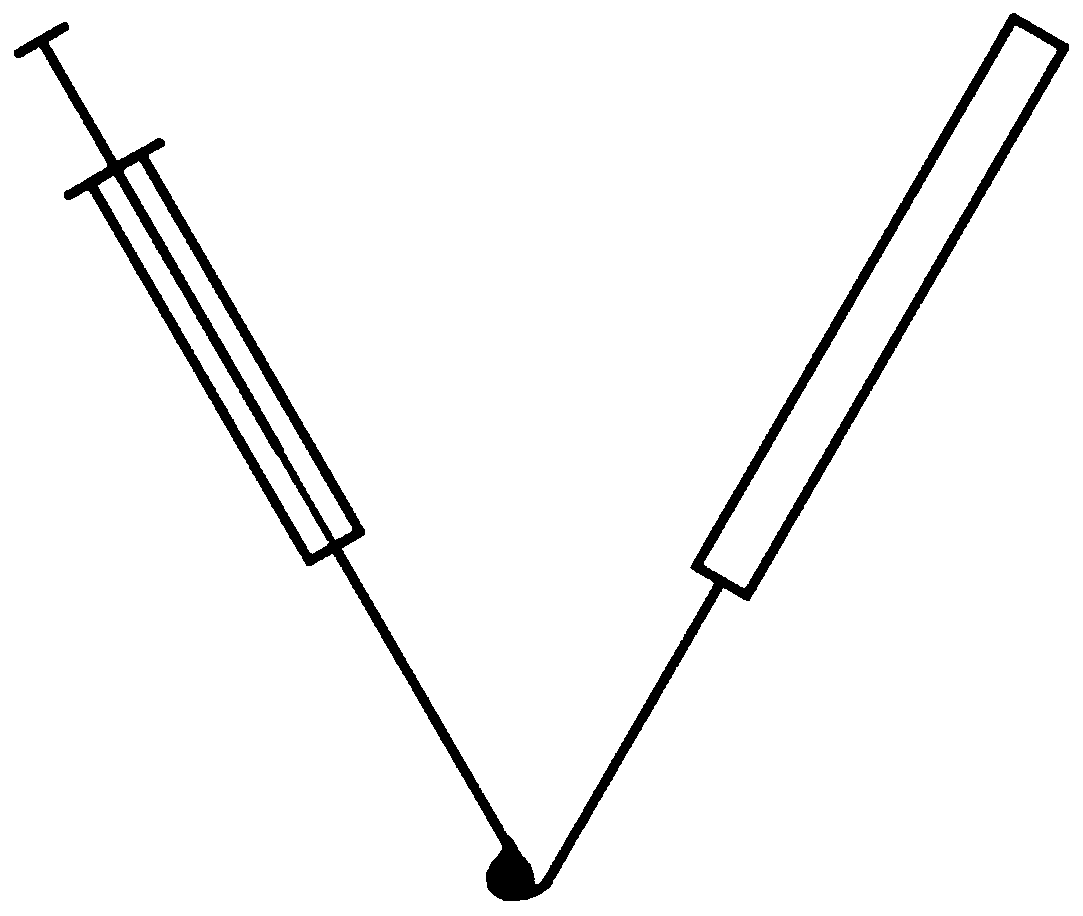

[0035] Wherein, the protective cover (2) is installed on the base (1), and is used to prevent chemical reagents from splashing out during the experiment. The protective cover top cover (3) is installed on the top of the protective cover (2), and the surface is provided with a number of holes with thumbscrew locking devices for installing the reagent adder (4) and the cleaner (5). The number of reagent adders (4) depends on actual needs, generally 2 to 4, and the number of cleaners (5) is generally 1 to 2. When adding liquid reagents, the reagent adder (4) uses an injection device in th...

Embodiment 2

[0041] The present invention is used for observing the reaction of ferric chloride solution and potassium thiocyanate solution

[0042] In this embodiment, a ferric chloride solution with a concentration of 0.015 mol / L and a potassium thiocyanate solution with a concentration of 0.015 mol / L are used for the reaction. Such as Figure 4 As shown, the process of the solution from nearly colorless to brown-red was clearly observed. It can be seen that the present invention is suitable for observing chemical reactions of discoloration.

Embodiment 3

[0044] The present invention is used for observing the reaction of silver nitrate solution and potassium chloride solution

[0045] In this embodiment, a silver nitrate solution with a concentration of 0.15 mol / L and a potassium chloride solution with a concentration of 0.15 mol / L are used for the reaction. Such as Figure 5 As shown, the process of the solution from clear to cloudy was clearly observed. It can be seen that the present invention is suitable for observing chemical reactions that produce precipitation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com