Short flow preparation method of high-strength and high-elasticity Cu-Ni-Mn alloy

A cu-ni-mn, high-elasticity technology, applied in the field of copper alloy materials, can solve the problems of easy oxidation, gas absorption, casting and preparation of Cu-Ni-Mn alloy materials, etc., achieve high strength, shorten the process flow, improve The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

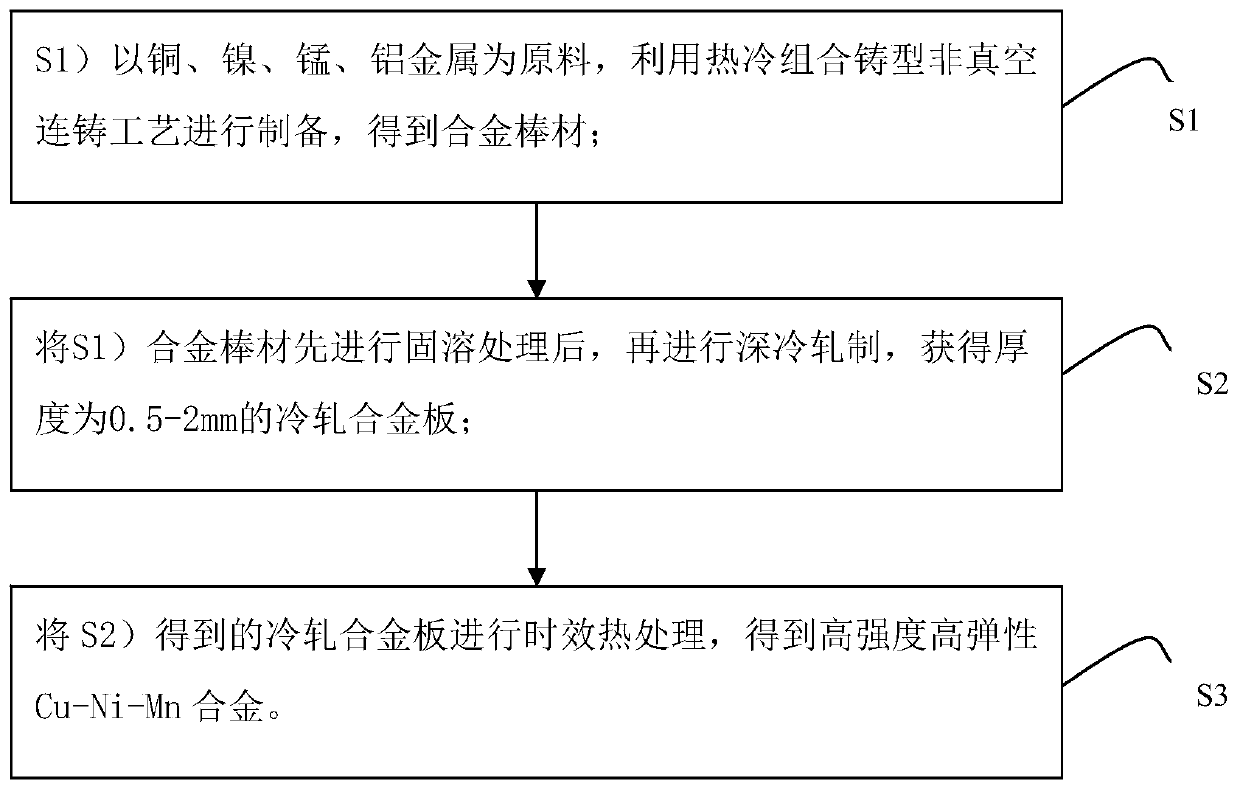

[0022] Such as figure 1 Shown, the short process preparation method of high-strength high-elasticity Cu-Ni-Mn alloy of the present invention, this method specifically comprises the following steps:

[0023] S1) using copper, nickel, manganese, and aluminum metals as raw materials, using a hot-cold combined mold non-vacuum continuous casting process to prepare alloy rods;

[0024] S2) performing solution treatment on the alloy bar of S1), and then performing cryogenic rolling to obtain a cold-rolled alloy plate with a thickness of 0.5-2mm;

[0025] S3) Perform aging heat treatment on the cold-rolled alloy sheet obtained in S2), to obtain a Cu-Ni-Mn alloy with high strength and high elasticity.

[0026] The mass percentages of each component of the raw materials in S1) are: Cu 45-70%, Ni 14-26%, Mn 14-26%, Al 0.1-5%, and the purity is greater than 99.9%.

[0027] The S1) raw material also includes boron with a purity greater than 99.9%, and the mass percentage is: 0.001-0.3%. ...

Embodiment 1

[0035] Example 1: Cu-20Ni-20Mn alloy

[0036] Prepare Cu-20Ni-20Mn alloy, comprises the steps:

[0037] (1) Continuous casting process: using pure copper, pure nickel, pure manganese, pure aluminum, and pure boron with a purity greater than 99.9% as raw materials, according to the main components, Cu element is 60wt%, Ni element is 20wt%, and Mn element is 20wt% %, is prepared by using hot-cold combined mold non-vacuum continuous casting process, the drawing temperature is 1250°C, the drawing speed is 1mm / s, and the cooling water is 600L / h, and a rod with a diameter of 20mm is obtained.

[0038] (2) Deformation process: After the alloy bar is subjected to solution treatment, it is subjected to 10 passes of deep cold rolling deformation at a temperature of -190 ° C, with a total deformation of 75%, and a cold-rolled alloy plate with a thickness of 1.5 mm is obtained;

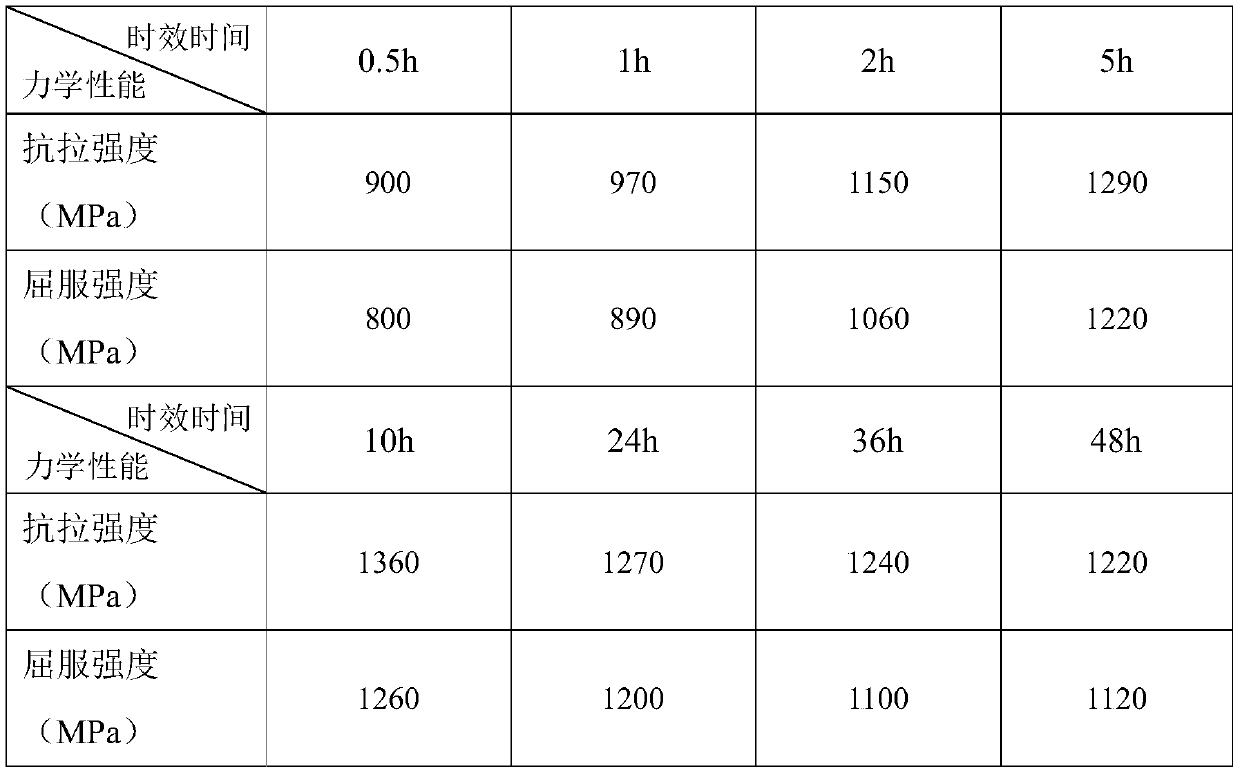

[0039] (3) Aging heat treatment: Heat the alloy plate after solution treatment and deep cold rolling to 400°C...

Embodiment 2

[0044] Example 2: Cu-20Ni-20Mn-0.05Al alloy

[0045] Prepare Cu-20Ni-20Mn-0.05Al alloy, comprising the following steps:

[0046] (1) Continuous casting process: using pure copper, pure nickel, pure manganese, pure aluminum, and pure boron with a purity greater than 99.9% as raw materials, according to the main components, the Cu element is 59wt%, the Ni element is 20wt%, and the Mn element is 20wt% %, the Al element is 0.05wt%, and it is prepared by hot-cold combined casting mold non-vacuum continuous casting process. The drawing temperature is 1250°C, the drawing rate is 1mm / s, and the cooling water is 600L / h, and a rod with a diameter of 20mm is obtained. .

[0047] (2) Deformation process: After the alloy bar is subjected to solution treatment, it is subjected to 10 passes of deep cold rolling deformation at a temperature of -190 ° C, with a total deformation of 75%, and a cold-rolled alloy plate with a thickness of 1.5 mm is obtained;

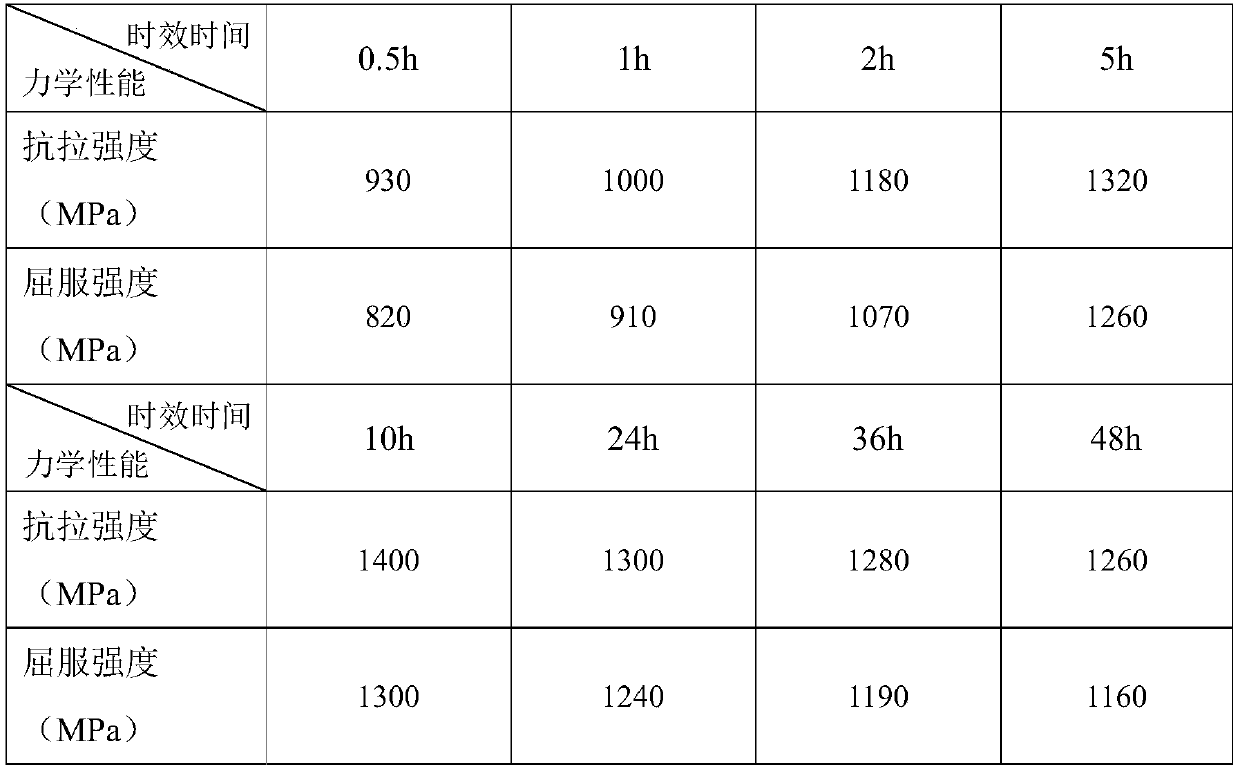

[0048](3) Aging heat treatment: He...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com