Sublimation workshop unorganized waste gas and dust recovery system

A technology of dust recovery and treatment system, applied in sublimation, combined device, transportation and packaging, etc., can solve the problems of product waste environment, dust volatilization, pollution, etc., and achieve the effect of saving resources, prolonging service life and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

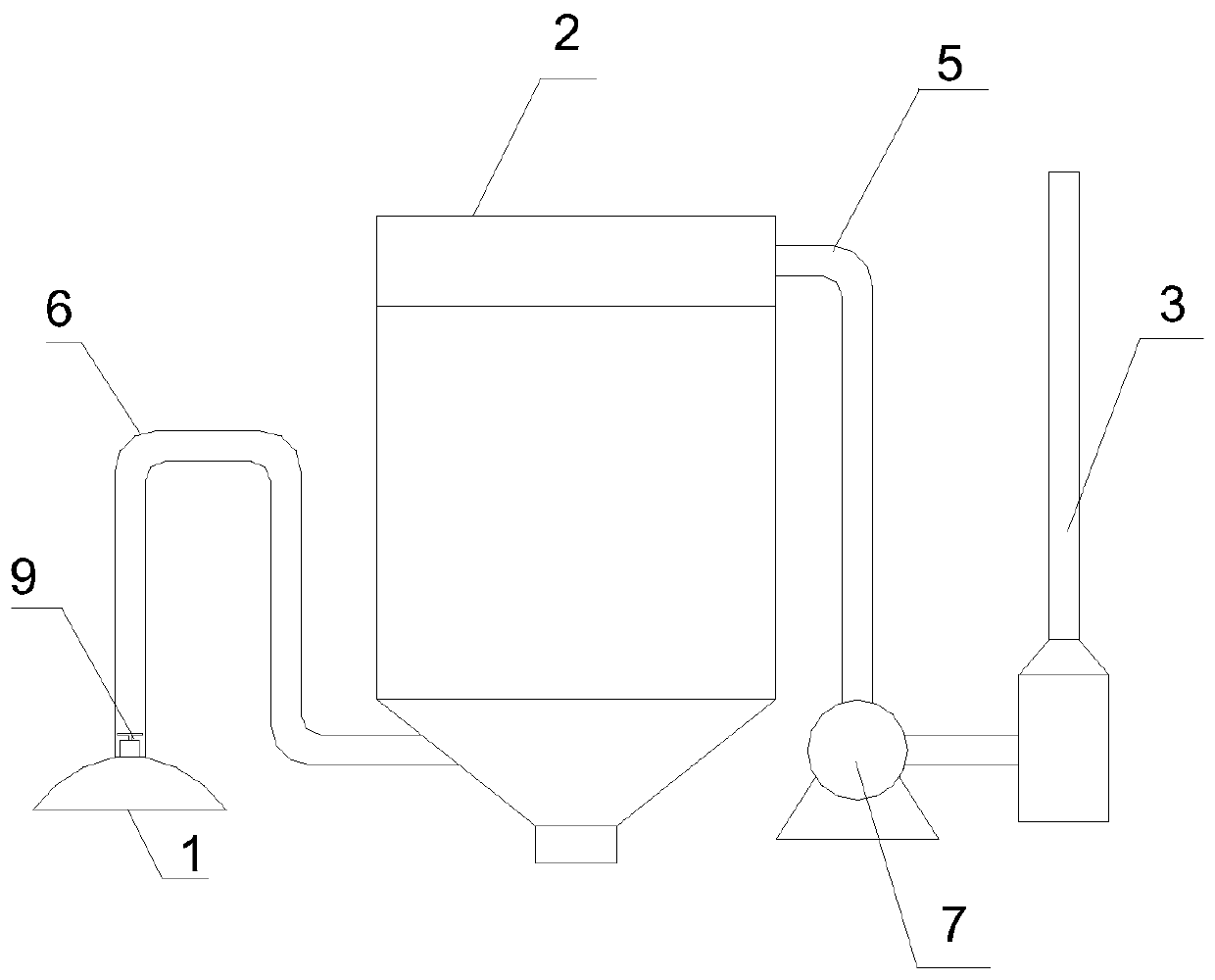

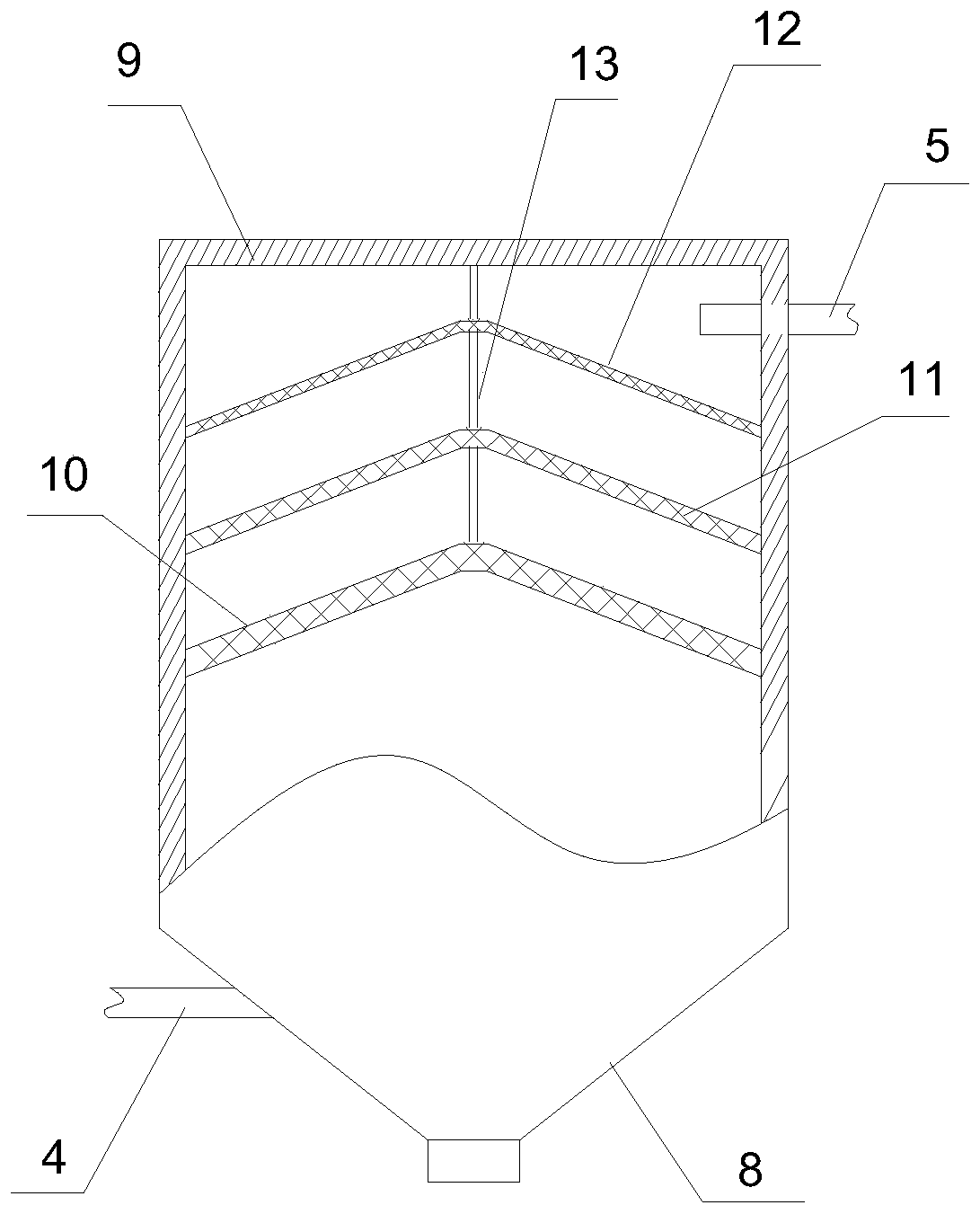

[0043] Such as Figure 1-5 As shown, the unorganized waste gas and dust recovery treatment system of the sublimation workshop of the present invention has the following general structure:

[0044]The recycling system is composed of a collection cover 1, a bag filter 2 and an exhaust tube 3 connected in series through pipelines. Specifically, the collection cover 1 and the bag filter 2 are connected through a first pipeline 4. The bag filter 2 and the exhaust cylinder 3 are connected through the second pipeline 5, the first pipeline 4 is provided with an induced draft fan 6 near the collection cover 1, and the second pipeline 5 is provided with a Fan 7, the fan 7 is a high-pressure and high-flow fan, which forms a waste gas and dust recovery and treatment system. The specific treatment process is: turn on the induced draft fan 6 and the fan 7, and first pass through the collection cover 1 to collect the unorganized waste gas generated in the sublimation workshop. and dust are ...

Embodiment approach 2

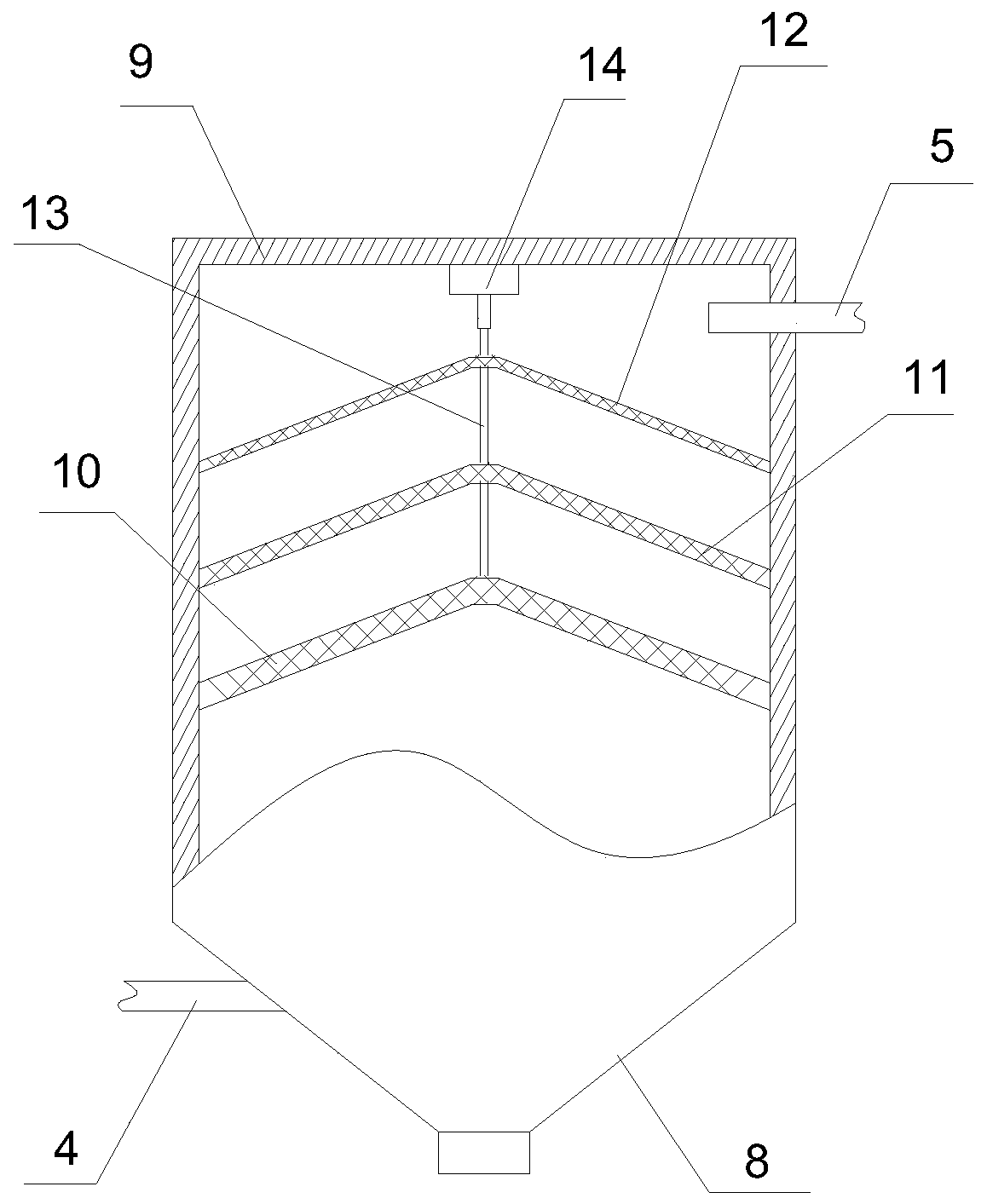

[0053] see Figure 6 Shown is the second embodiment of the exhaust gas and dust recovery treatment system of the present invention. The difference between this embodiment and the first embodiment is that in order to realize the protection of the filter bag and to collect the dust into the ash hopper for convenience, the The surrounding edges of the first filter bag 10, the second filter bag 11 and the third filter bag 12 are respectively connected with a first filter disc 17, a second filter disc 18 and a third filter disc 19, the first filter disc 17, The second filter disc 18 and the third filter disc 19 are respectively evenly distributed with the same holes as the apertures on the first filter bag 10, the second filter bag 11 and the third filter bag 12, and the first filter disc 17 , the second filter disc 18 and the third filter disc 19 are disc-shaped structures, and the peripheries of the first filter disc 17, the second filter disc 18 and the third filter disc 19 are ...

Embodiment approach 3

[0056] see Figure 7 Shown is the third embodiment of the exhaust gas and dust recovery and treatment system of the present invention. The difference between this embodiment and the second embodiment is that the recovery and treatment system further includes a cooling device, and the cooling device includes a water tank 23, a water pump 24 and the spiral cooling groove 25, the spiral cooling groove 25 is arranged in the bag filter 2, and is located at the bottom of the bag filter 2, and the outlet of the first pipeline 4 is located below the spiral cooling groove 25, the The two ends of the spiral cooling tank 25 are connected with a water inlet pipe 26 and an outlet pipe 27. The other end of the water inlet pipe 26 passes through the bag filter 2 and extends into the water tank 23. The water tank 23 is preferably fixedly connected to the bag filter. 2, and the water pump 24 is connected to the water inlet pipe 26 for pumping the cooling water in the water tank 23 into the spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com