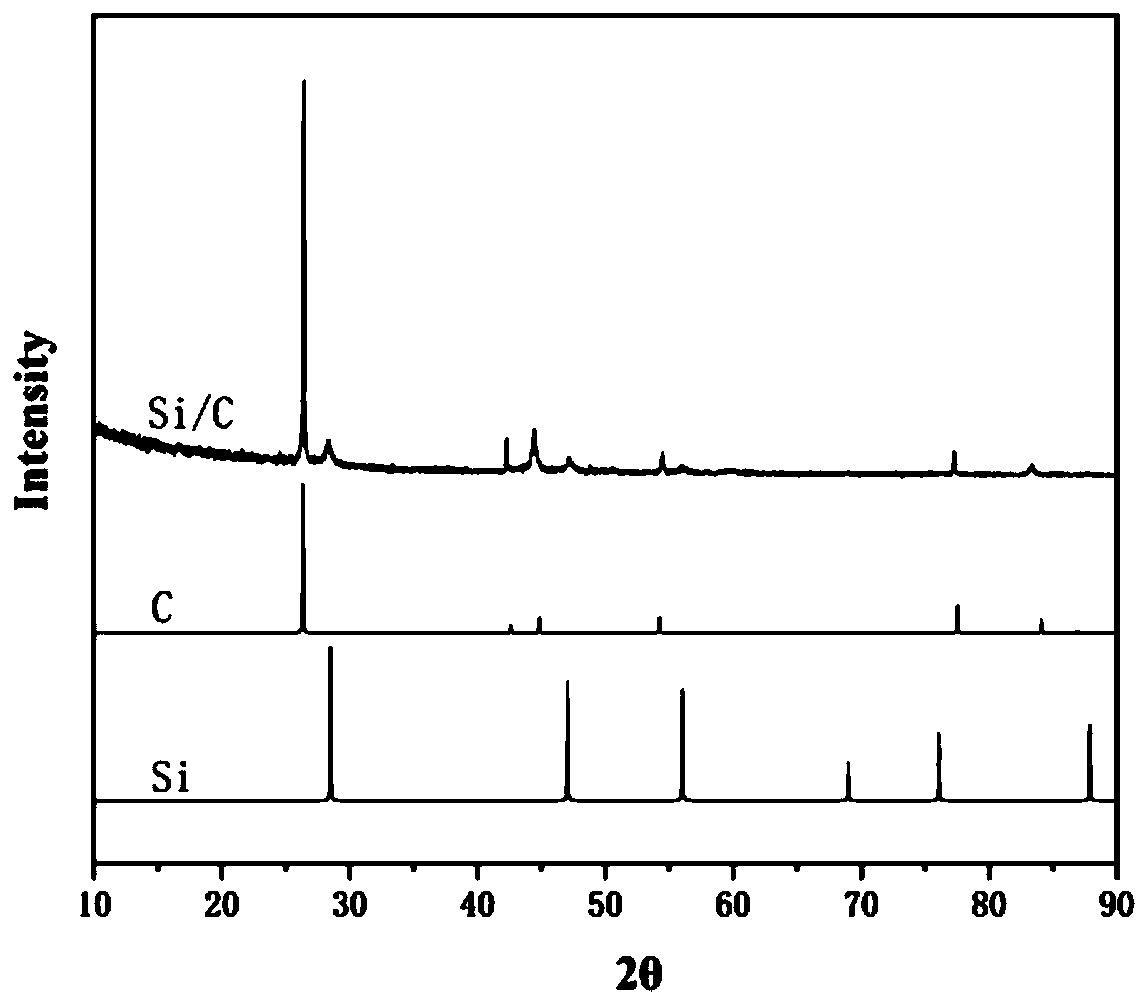

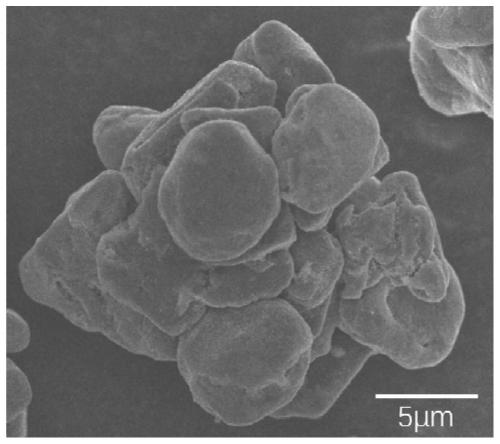

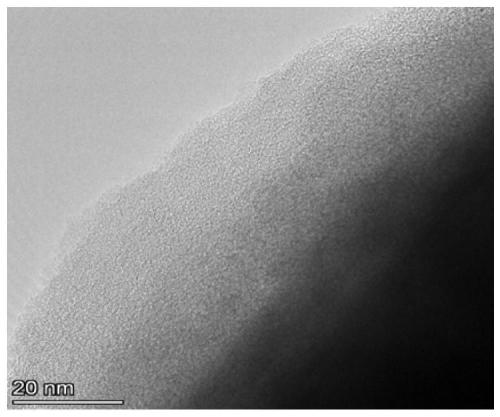

Silicon-carbon composite material with multi-layer coating structure and preparation method thereof

A silicon-carbon composite material and coating structure technology, applied in structural parts, carbon compounds, chemical instruments and methods, etc., can solve the problems of active lithium ion and electrolyte consumption, low battery coulomb efficiency, SEI film rupture, etc. Improve coulombic efficiency and cycle retention, reduce side reactions, and reduce consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0043] Step 1: Weigh 1 part of nano-silicon, mix it with 8 parts of ethanol and grind it in a sand mill to obtain an ethanol dispersion of D50 silicon at 150 nm;

[0044] Step 2: Weigh 8 parts of graphite with a D50 of 5 μm, and add it into the ethanol dispersion of nano-silicon, and stir evenly to obtain the ethanol dispersion of nano-silicon and graphite;

[0045] Step 3: Add 0.4 parts of asphalt with a softening point of 160°C and a particle size of D50 of 1.8 μm into the dispersion of nano-silicon and graphite and mix evenly;

[0046] Step 4: Spray-dry the ethanol dispersion of nano-silicon, graphite and asphalt, and the spray-drying temperature is 160°C to obtain a dry powdery single-stage coated silicon-carbon material precursor;

[0047] Step 5: Weigh 0.8 parts of high-temperature asphalt (softening point is 260°C, coking value is 70%, particle size is 3 μm), and mix it with the single-stage coated silicon carbon material precursor evenly, then add it to the high-temper...

Embodiment approach 2

[0083] Step 1: Weigh 2 parts of nano-silicon, mix it with 10 parts of ethanol and grind it in a sand mill to obtain an ethanol dispersion of D50 at 200nm silicon;

[0084] Step 2: Weigh 10 parts of graphite with a D50 of 7 μm, and add it into the ethanol dispersion of nano-silicon, and stir evenly to obtain the ethanol dispersion of nano-silicon and graphite;

[0085] Step 3: Add 0.5 parts of asphalt with a softening point of 160°C and a particle size of D50 of 1.5 μm into the dispersion of nano-silicon and graphite and mix evenly;

[0086] Step 4: Spray-dry the ethanol dispersion of nano-silicon, graphite and pitch at a spray-drying temperature of 180°C to obtain a dry powder single-stage coated silicon-carbon material precursor;

[0087] Step 5: Weigh 1 part of high-temperature pitch (softening point of 250°C, coking value of 70%, particle size of 3 μm), and mix it with the single-stage coated silicon carbon material precursor evenly, then add it to the high-temperature VC m...

Embodiment approach 3

[0090] Step 1: Weigh 1 part of nano-silicon, mix it with 7 parts of methanol, and grind it in a sand mill to obtain a D50 dispersion of 150nm silicon;

[0091] Step 2: Weighing 8 parts of graphite with a D50 of 5 μm, and adding it to the nano-silicon dispersion, stirring evenly to obtain a mixed dispersion of nano-silicon and graphite;

[0092] Step 3: Add 0.4 parts of asphalt with a softening point of 160°C and a particle size of D50 of 1.3 μm into the dispersion of nano-silicon and graphite and mix evenly;

[0093] Step 4: Spray-dry the dispersion of nano-silicon, graphite and asphalt, and the spray-drying temperature is 210°C to obtain a dry powder single-stage coated silicon-carbon material precursor;

[0094] Step 5: Weigh 0.8 parts of high-temperature asphalt (softening point is 260°C, coking value is 70%, particle size is 3 μm), and mix it with the single-stage coated silicon carbon material precursor evenly, then add it to the high-temperature VC mixer, under nitrogen C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com