Laminated silicon-rich silicon carbide thin-film solar cell and preparation method thereof

A silicon-rich silicon carbide and solar cell technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problem that the size and uniformity of silicon quantum dots are difficult to control, the photoelectric conversion efficiency of solar cells is reduced, and the low energy consumption in the preparation process cannot be realized. problems, to achieve the effect of broadening the spectral response range, reducing the preparation cost and avoiding energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

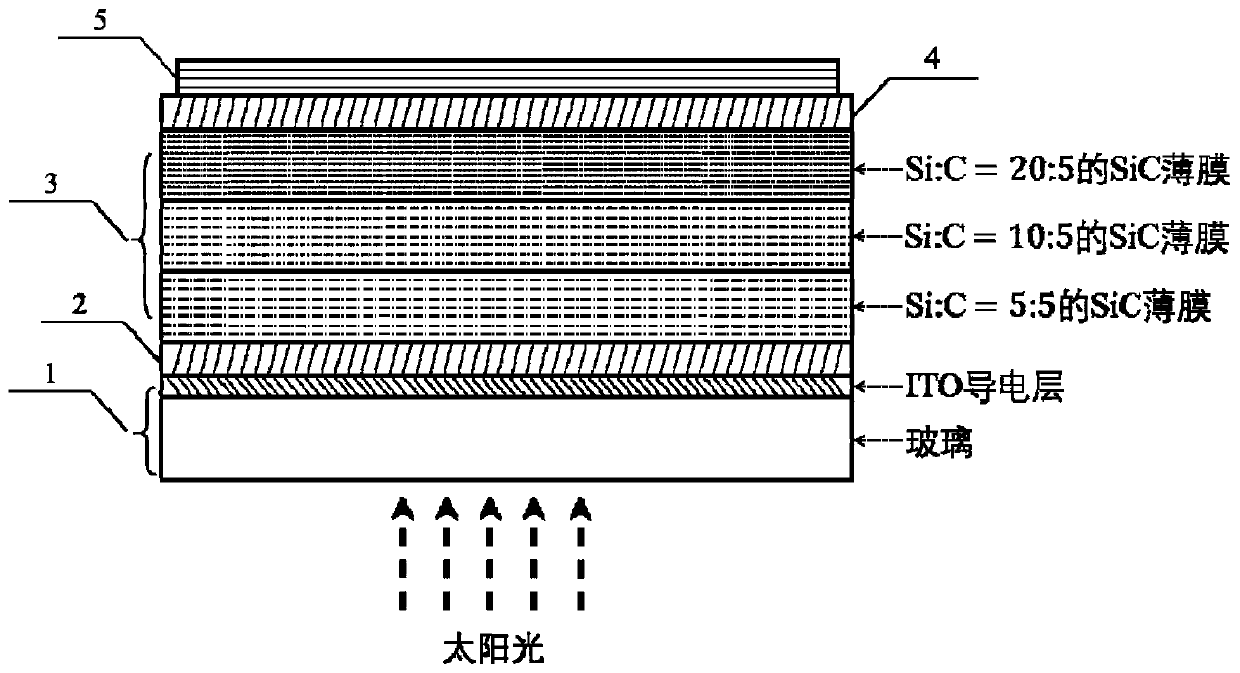

[0025] Such as figure 1 As shown, the stacked silicon-rich silicon carbide thin film solar cell according to the present invention, its structure includes from bottom to top: ITO conductive glass 1; boron-doped amorphous silicon carbide (B-doped a-SiC) thin film 2, thin film The thickness is 10nm; a laminated silicon-rich silicon carbide film 3 with a film thickness of 60nm; a phosphorus-doped amorphous silicon carbide (P-doped a-SiC) film 4 with a film thickness of 10nm; an aluminum Al electrode 5 . Among them, the stacked silicon-rich silicon carbide film is composed of three layers of silicon-rich silicon carbide films with different silicon-to-carbon ratios.

[0026] The preparation method of the stacked silicon-rich silicon carbide thin film solar cell described in the present invention is as follows:

[0027] (1) Selec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com