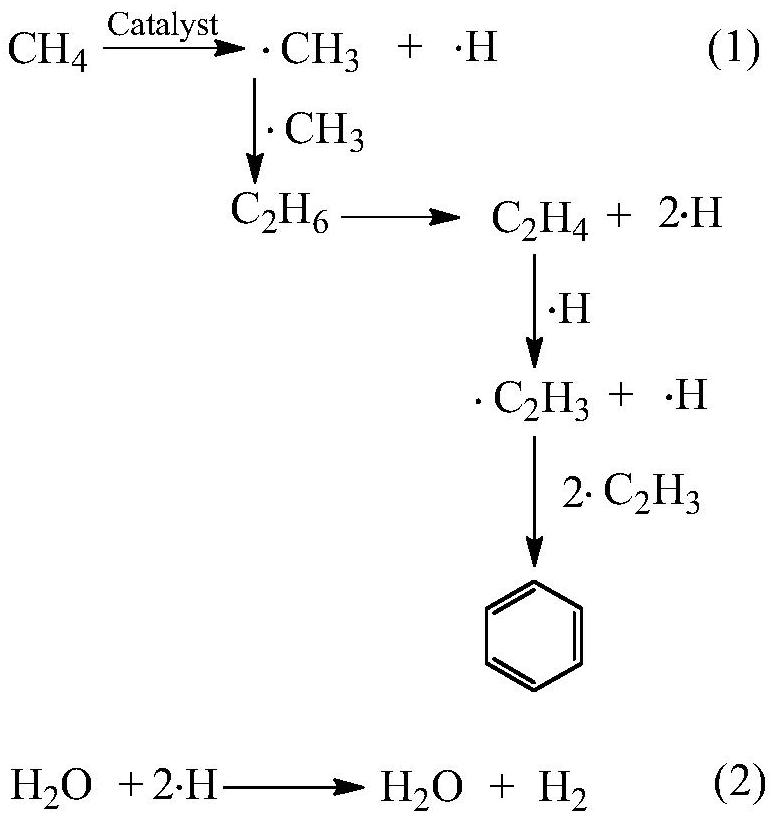

A method for steam catalytic conversion of methane to olefins, aromatics and hydrogen

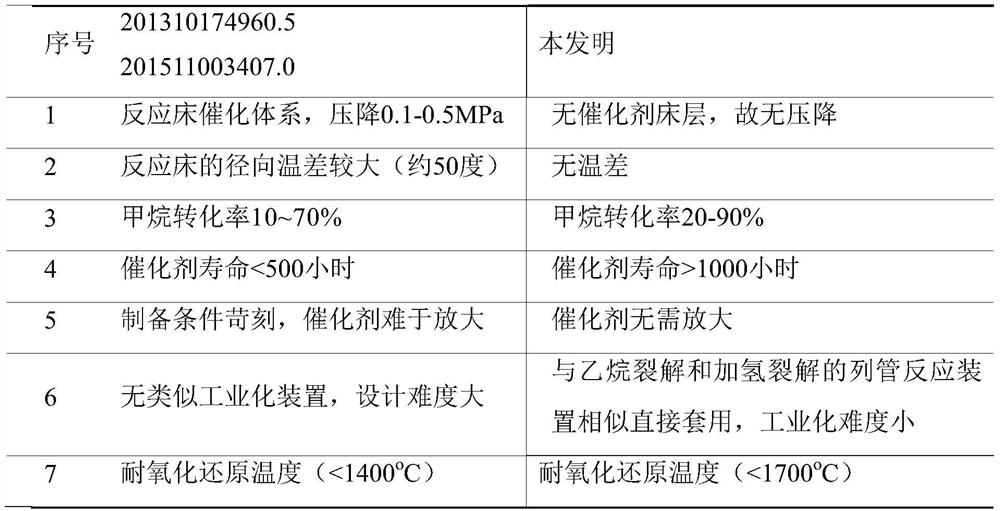

A technology for producing olefins and methane, which is applied in chemical instruments and methods, catalysts, carbon compound catalysts, etc., and can solve the problems of harsh catalyst preparation conditions, difficult scale-up, poor thermal conductivity of catalysts, and large bed temperature difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] 1. Preparation of catalytic reactor (thin layer thickness and active component content need to be indicated)

[0061] The preparation method of the lattice doped catalyst includes chemical vapor deposition (MCVD) coating solid-phase doping technology or solid-liquid phase sol-gel combined with high-temperature melting coating technology. Membrane catalysts are marked as:

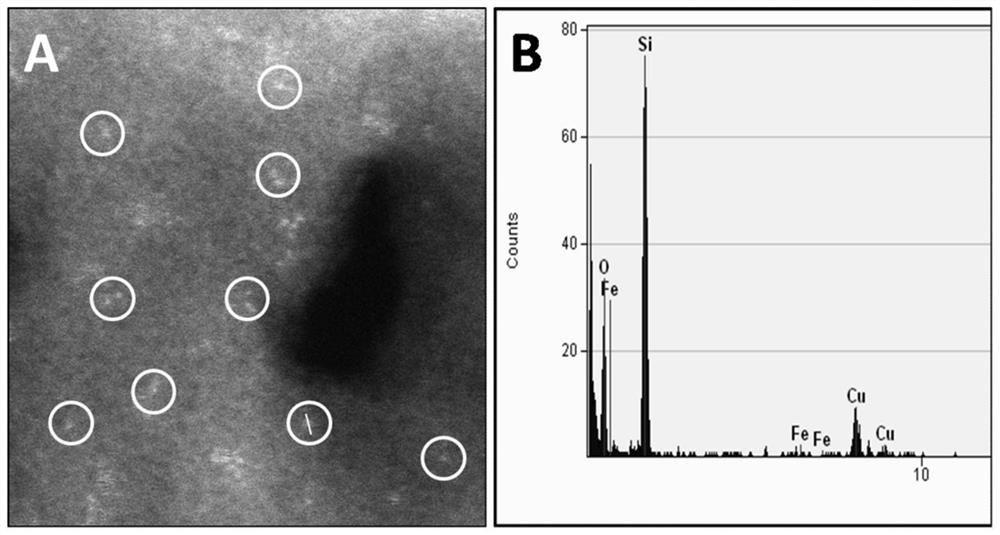

Embodiment 1

[0064] Modified Chemical Vapor Deposition (MCVD)

[0065] Use 30mL / min of high-purity oxygen to SiCl 4 Liquid and FeCl under saturated vapor pressure at 350°C using 200mL / min high-purity helium 3 The gas is brought into the high-temperature MCVD device, and the inner wall of the quartz tube (wall thickness 1.5mm) with an outer diameter of 20 mm and a length of 100 mm is heated at 1600 ° C by SiCl 4 and FeCl 3 After 10 min of oxide deposition, Fe-doped SiO was obtained 2 The powder material is then melted for 40 minutes at a temperature of 1980°C under a 2bar high-purity helium atmosphere to form a thin layer of dopant with a thickness of 100nm on the inner wall of the reactor, and then naturally cooled to obtain a 20mm in diameter and 100mm in length Catalytic quartz reactor, wherein Fe doping amount is 0.05wt.%.

Embodiment 2

[0067] Modified Chemical Vapor Deposition (MCVD)

[0068] Use 30mL / min of high-purity oxygen to SiCl 4 Liquid and FeCl under saturated vapor pressure at 350°C using 650mL / min high-purity helium 3 The gas is brought into the high-temperature MCVD device, and the inner wall of the quartz tube (wall thickness 1.5mm) with an outer diameter of 20 mm and a length of 100 mm is heated at 1600 ° C by SiCl 4 and FeCl 3 After 10 min of oxide deposition, Fe-doped SiO was obtained 2 The powder material is then melted for 40 minutes at a temperature of 1980°C under a 2bar high-purity helium atmosphere to form a thin layer of dopant with a thickness of 100nm on the inner wall of the reactor, and then naturally cooled to obtain a 20mm in diameter and 100mm in length Catalytic quartz reactor, wherein Fe doping amount is 0.1wt.%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com