Nanometer zinc oxide, preparation method thereof and desulfurizing agent

A nano-zinc oxide and desulfurizer technology, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, etc., can solve the problems of little active zinc oxide, wide product particle size distribution, and reduced specific surface area, so as to reduce the calcination temperature , Improve the purity and reduce the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

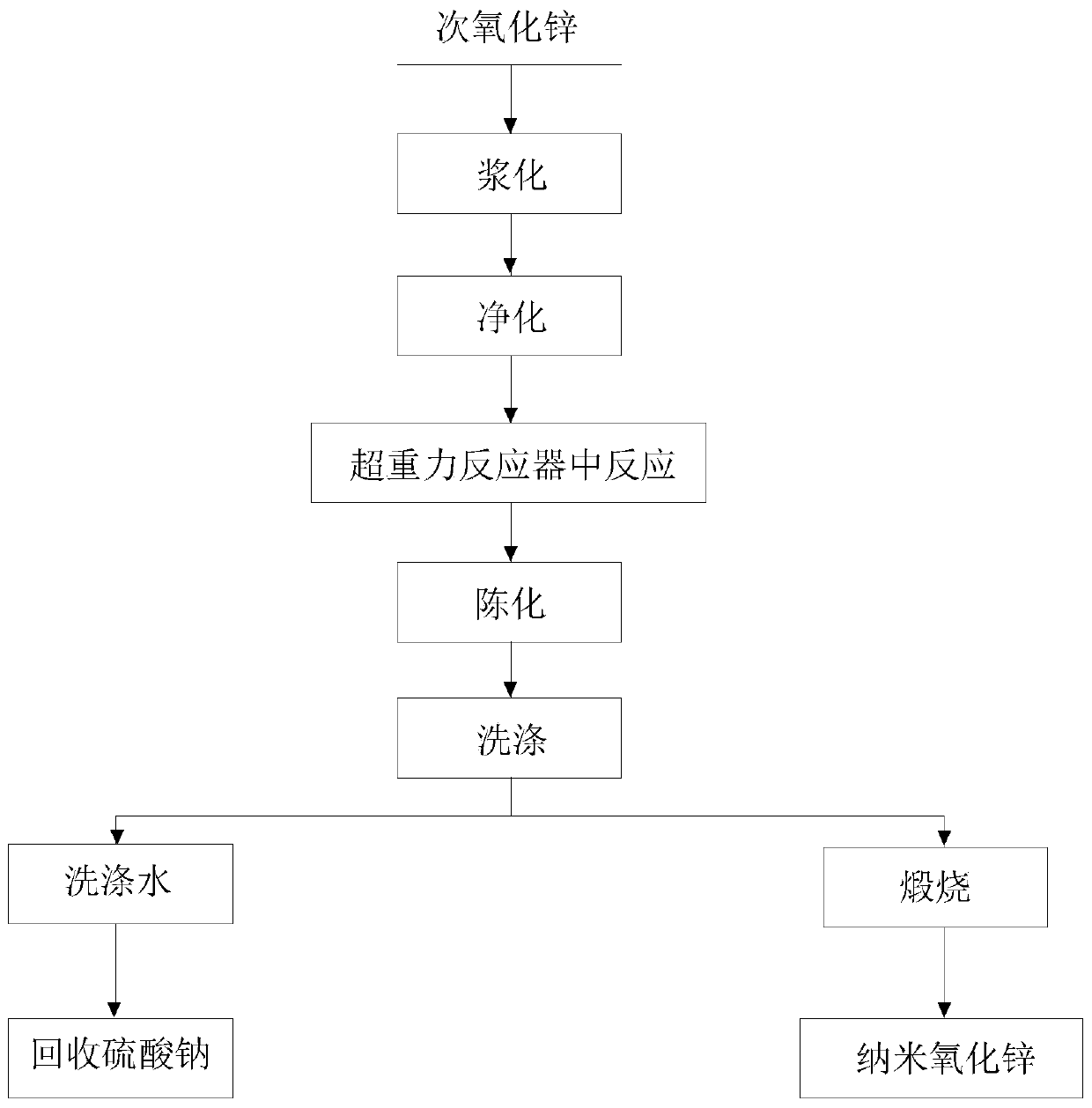

[0049] For details, please refer to figure 1 , a preparation method of nano-zinc oxide, which comprises:

[0050] S1. Obtain zinc sulfate solution and soda ash solution.

[0051] Among them, the zinc sulfate solution includes allowed impurities, and the impurities mainly include Fe 2+ 、Cu 2+ , Mn 2+ and Cd 2+ , and when [Zn 2 + ]=100g / L, [Fe 2+ ]2+ ]≤2mg / L, [Cu 2+ ]2+ ]<2mg / L.

[0052] When the impurity includes in addition to protecting Fe 2+ 、Cu 2+ , Mn 2+ and Cd 2+ In addition, it also includes Al 3+ , when the zinc sulfate solution [Zn 2+ ]=100g / L, [Al 3+ ]<10mg / L.

[0053] Zinc sulfate solution can be prepared by yourself or purchased, as long as it meets the above requirements.

[0054] Alternatively, the zinc sulfate solution is prepared by:

[0055] (1) obtain zinc sulfate crude liquid

[0056] Optionally, the crude zinc sulfate solution is put into water by sub-zinc oxide for leaching and slurrying, until the leachate pH=5 and [Zn 2 + ]=60-105g / L,...

Embodiment 1

[0092] Zinc sulfate solution is prepared by the following method:

[0093] A. Put 1 part by weight of zinc oxide into 4-8 parts by weight of water for leaching until pH=5 and [Zn 2+]=100g / L, filter, obtain zinc sulfate thick liquid.

[0094] B. Detect the iron content in the crude zinc sulfate solution. After calculation, add quantitative hydrogen peroxide and continue stirring for 10 minutes. Then according to the amount of hydrogen peroxide added, drop into calcium carbonate in proportion to carry out hydrolysis iron removal, adjust pH value=5, stir 10min, get filtrate detection, [Fe 2+ ] < 2mg / L, the material enters the plate and frame filter press for filtration to obtain the zinc sulfate crude liquid after iron removal.

[0095] C. Check the aluminum content in the crude zinc sulfate solution after iron removal, raise the temperature to 60-70°C, add the quantitative flocculant obtained after calculation, stir for 20 minutes and then let it settle for 3 hours, then the m...

Embodiment 2

[0100] A kind of nano zinc oxide, it is made by following preparation method:

[0101] Zn in the supernatant that embodiment 1 obtains 2+ The concentration was adjusted to 100g / L as the zinc sulfate solution used in this embodiment.

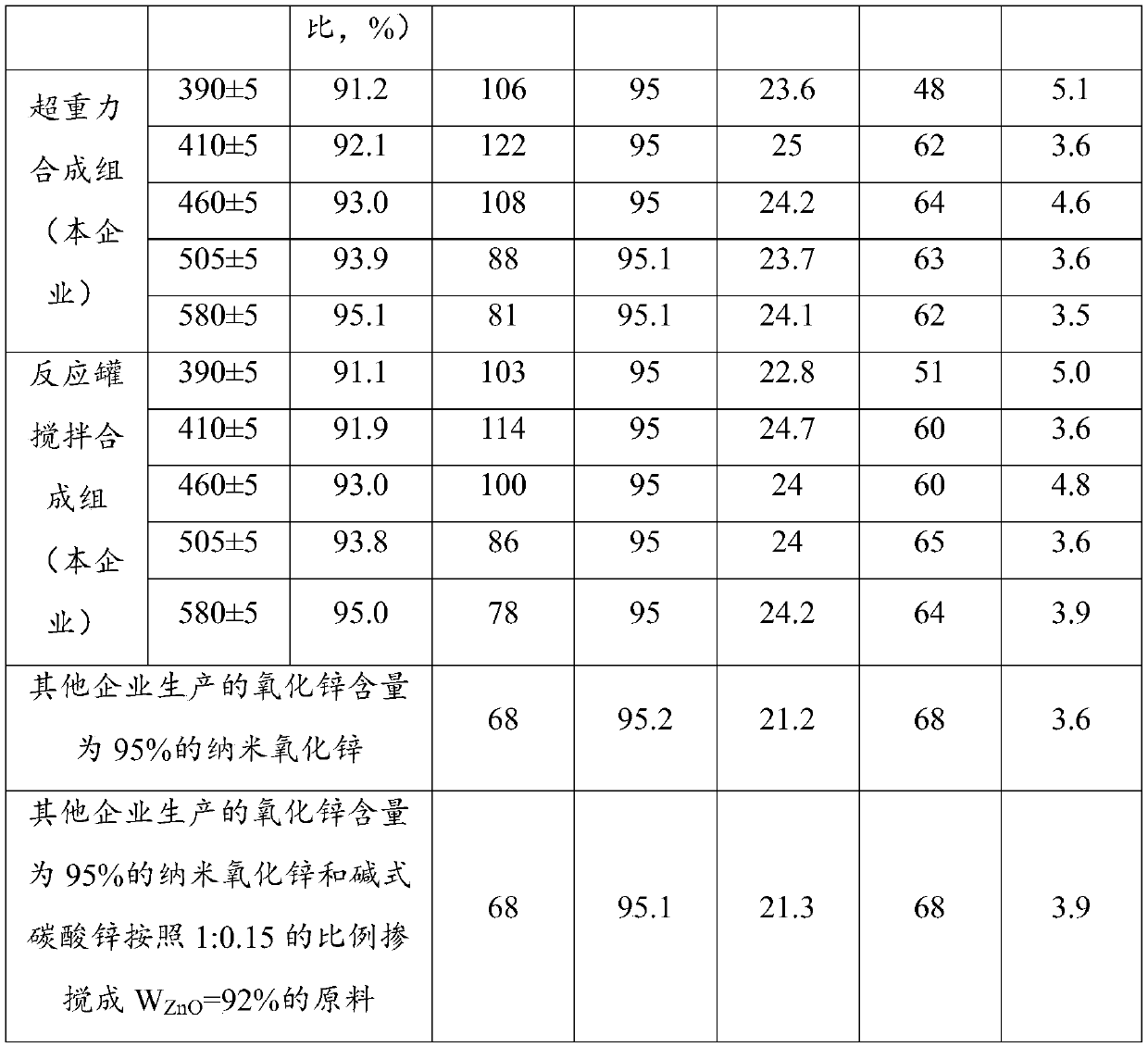

[0102] Get 1 volume part of zinc sulfate solution and 0.65 volume parts of concentration and be 20wt% soda ash solution, at 50 ℃, press the feed total amount of zinc sulfate solution and soda ash solution to be 18m 3 / h and the flow rate ratio of zinc sulfate solution to soda ash solution is 1:0.65 into the hypergravity reactor for neutralization reaction to generate precursor slurry.

[0103] Put the precursor slurry obtained after the reaction into the reaction tank, stir, adjust the pH value to 7, raise the temperature to 80°C, stir for 30 minutes, let it stand and age for 3 hours, then wash with water, press filter to obtain a water content of 50±1% precursors. The washed water is reclaimed, and sodium sulfate is reclaimed according to rel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com