Throttling control propulsion valve bank

A throttling control and valve group technology, applied in servo motor components, fluid pressure actuating devices, mechanical equipment, etc., can solve the problems of the main valve not working and the valve core not being able to be completely switched, so as to prolong the service life and reduce the pressure. Shock peak, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

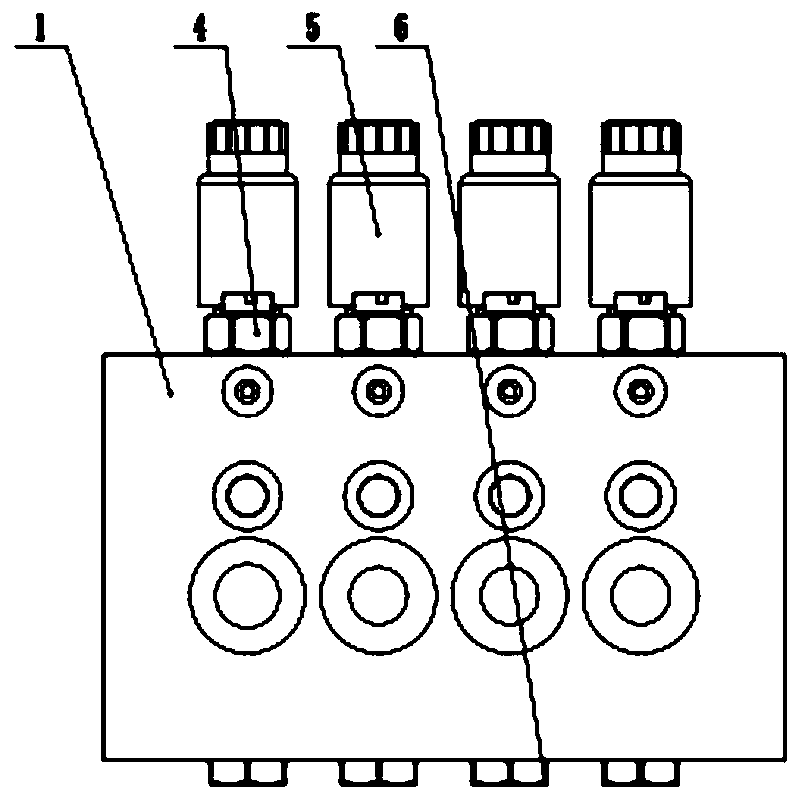

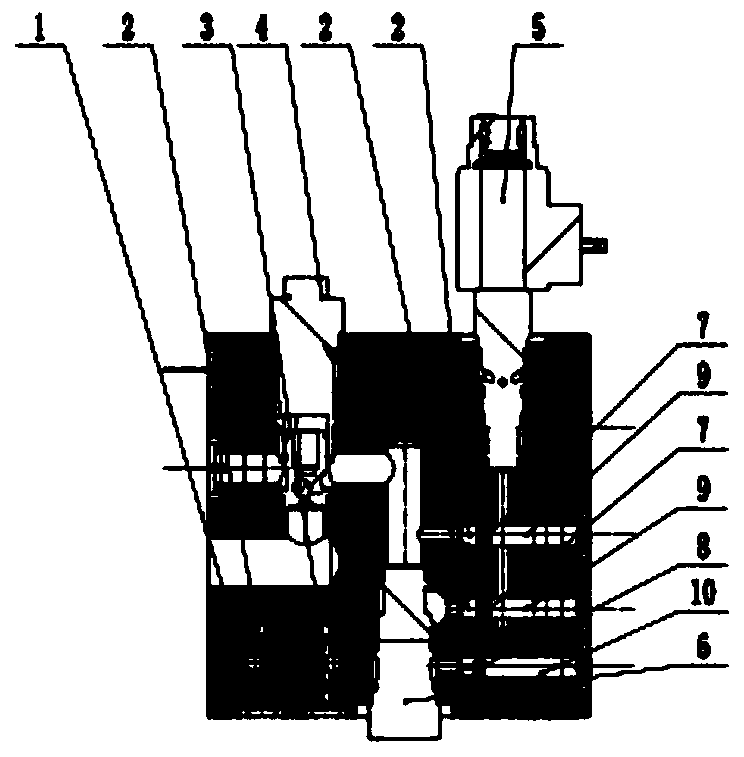

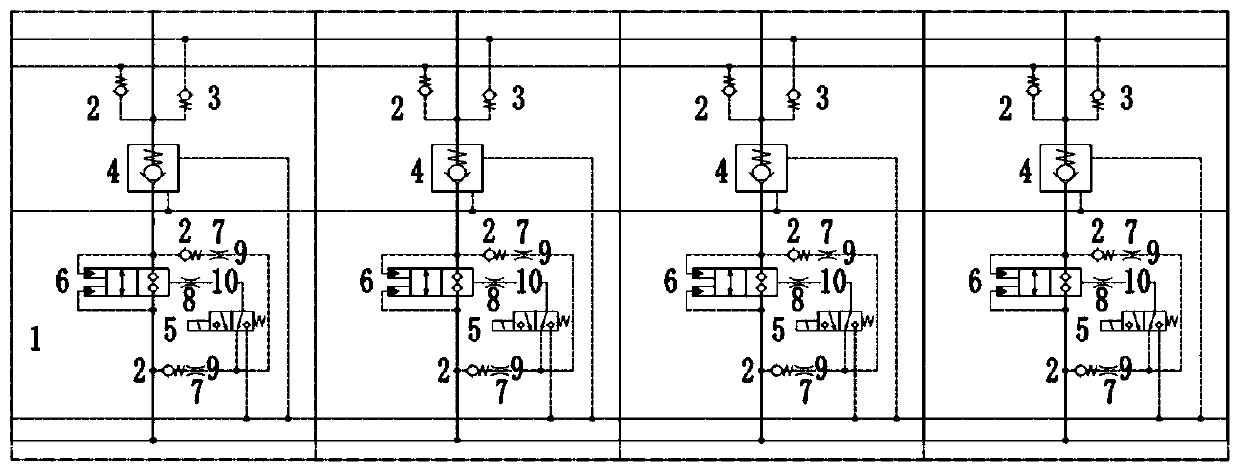

Image

Examples

Embodiment Construction

[0018] When the shield machine is working, the hydraulic system is always in a high-pressure state. With the prolongation of the working time, the temperature of the hydraulic oil gradually increases, resulting in a decrease in the viscosity of the oil, which enters the pilot control oil passage 1 (9 ) gradually increases, when the flow exceeds the working flow of the electromagnetic reversing valve (5), the electromagnetic reversing valve (5) will fail to work, which will affect the work of the pilot control logic valve (6), causing the propulsion system Work is unstable. By adding throttling damper one (7) to each of the two pilot control oil passages one (9), adjust the throttling damper one (7) to control the flow into the electromagnetic reversing valve (5), so that the flow rate is within the rated range , to ensure the stable operation of the pilot control logic valve (6).

[0019] During the switching process of the pilot control logic valve (6), the switching respons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com