Method for recovering cobalt and lithium metals in waste lithium-ion battery

A lithium-ion battery and recycling method technology, applied in the field of lithium-ion battery recycling, can solve the problems of secondary pollution of reagents, consumption of large organic solvents, secondary pollution of water bodies, etc., to reduce energy consumption and cost, facilitate industrial production, and avoid The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

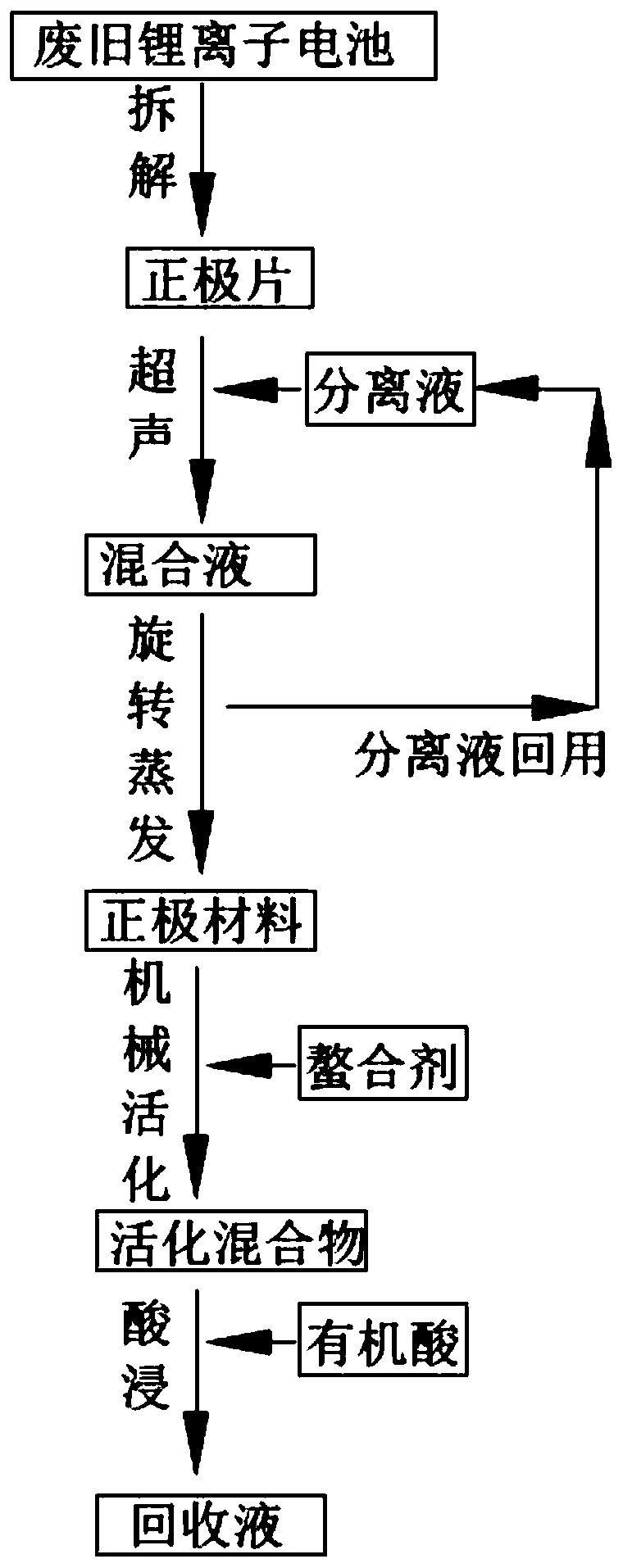

Image

Examples

Embodiment 1

[0040] (1) Take a certain brand of waste lithium-ion battery and manually disassemble it to obtain 200g of positive electrode sheet containing aluminum foil and positive electrode material;

[0041] (2) Cut the 30g positive electrode sheet into small pieces with a length of 5cm and a width of 6cm and soak them in 100mL DMAC. Place the beaker containing the positive electrode sheet and separation liquid in an ultrasonic environment. Time 60min, then take out the aluminum foil to obtain the mixed solution;

[0042] (3) The mixed solution containing the positive electrode material was obtained by rotary evaporation at 80° C. to obtain a solid substance, and the solid substance was dried at 105° C. to obtain 14.3 g of the positive electrode material of a lithium ion battery;

[0043] (4) After mixing 10 g of positive electrode material with 10 g of nitrilotriacetic acid, perform mechanical ball milling, the ball milling speed is 400 rpm, the ball milling time is 90 min, and the ba...

Embodiment 2

[0047] (1) Take a certain brand of waste lithium-ion battery and manually disassemble it to obtain 300g of positive electrode sheet containing aluminum foil and positive electrode material;

[0048] (2) Cut the 40g positive electrode sheet into small pieces with a length of 5cm and a width of 6cm and soak them in 150mL DMAC. Time 60min, then take out the aluminum foil to obtain the mixed solution;

[0049](3) The mixed solution containing the positive electrode material was obtained by rotary evaporation at 80°C to obtain a solid substance, and the solid substance was dried at 105°C to obtain 25.6g of the positive electrode material of the lithium ion battery;

[0050] (4) Take 25.6g of the positive electrode material and mix it with 30g of sodium aminotriacetate, then carry out mechanical ball milling treatment, the ball milling speed is 500rpm, the ball milling time is 90min, the ball to material ratio is 3g / g, and 54.8g of the activated mixture is obtained;

[0051] (5) 54...

Embodiment 3

[0054] (1) Take a certain brand of waste lithium-ion battery and manually disassemble it to obtain 200g of positive electrode sheet containing aluminum foil and positive electrode material;

[0055] (2) Cut the 30g positive plate into small pieces with a length of 5cm and a width of 6cm and soak them in 100mL DMAC. Time 80min, then take out the aluminum foil to obtain the mixed solution;

[0056] (3) The mixed solution containing the positive electrode material was obtained by rotary evaporation at 80° C. to obtain a solid substance, and the solid substance was dried at 105° C. to obtain 15.8 g of the positive electrode material of a lithium ion battery;

[0057] (4) Take 15.8g of positive electrode material and 20g of disodium ethylenediaminetetraacetate and mix them with mechanical ball milling. The ball milling speed is 500rpm, the ball milling time is 90min, and the ball to material ratio is 3g / g to obtain 35.1g of the activated mixture;

[0058] (5) Mix 35.1g of the acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com