Semiconductor device and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problems of improvement, inability to perform electrical connection, and inability to optimize the electrical performance of back-illuminated CMOS image sensors. Performance optimization, electrical performance improvement, effect of electrical performance optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] A fabrication process of a metal grid layer in a pixel area is as follows:

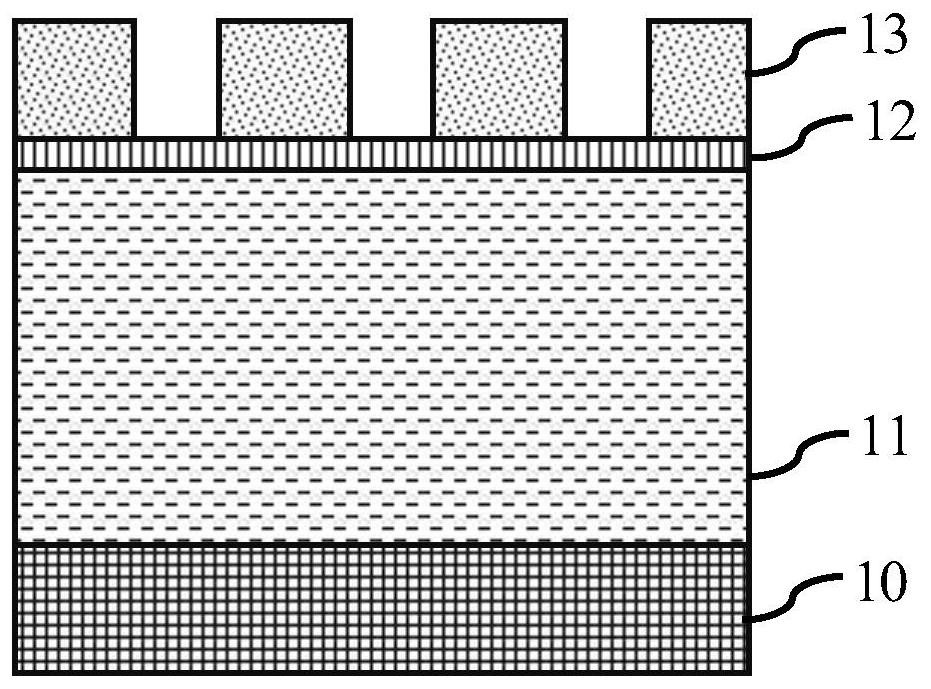

[0060] like Figure 1a As shown, a substrate 10 having a pixel region 11 is provided;

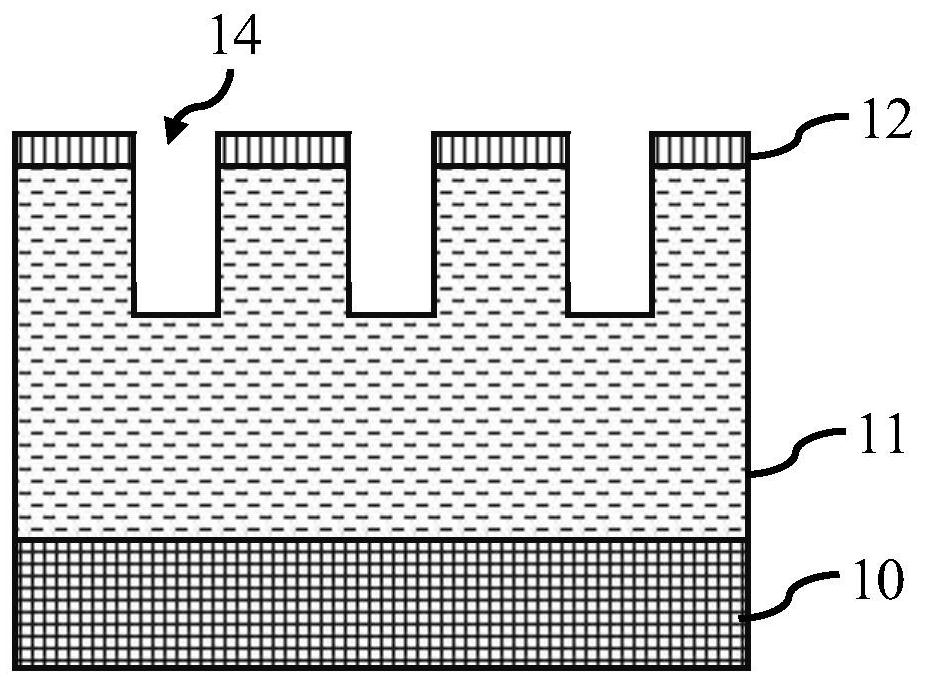

[0061] like Figure 1a and 1b As shown, a pad oxide layer 12 is formed on the pixel region 11 , a first patterned photoresist layer 13 is formed on the pad oxide layer 12 , and the first patterned photoresist layer 13 is formed on the pad oxide layer 12 . As a mask, the pad oxide layer 12 on the pixel area 11 and the substrate 10 with a partial thickness are etched to form trenches 14 in the substrate 10 of the pixel area 11, and the a patterned photoresist layer 13;

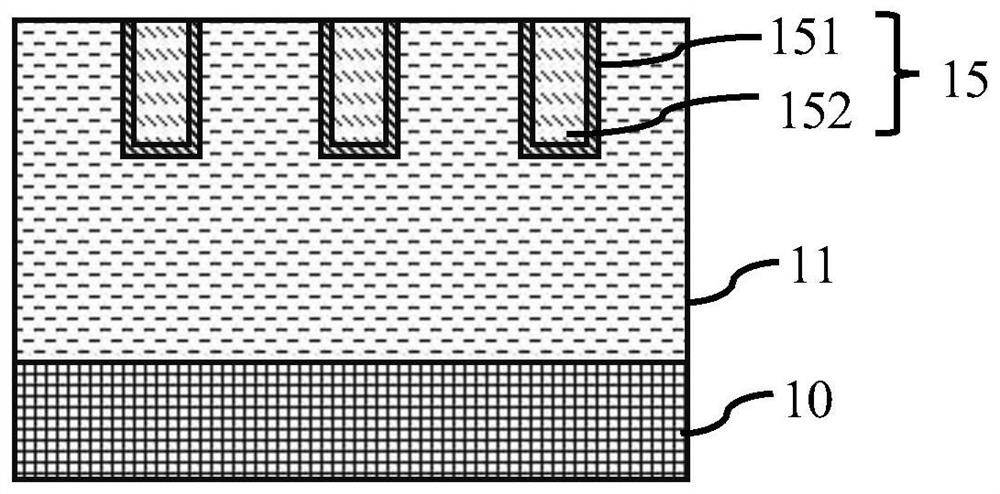

[0062] like Figure 1c As shown, an isolation oxide layer 151 is formed on the surface of the trench 14 and the surface of the pad oxide layer 12, and a conductive metal layer 152 is filled in the trench 14, and the conductive metal layer 152 covers all the On the pad oxide layer 12 , the conductive metal layer 152 , the isolation oxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com