A method for vanadium-containing stone coal decarburization-crystal breaking roasting enhanced acid leaching vanadium extraction

An acid leaching and decarbonization technology, applied in the field of vanadium extraction from stone coal, can solve the problems of poor oxidation uniformity of the inner and outer layers of the pellets, easy under-burning or over-burning of the rotary kiln, low energy utilization rate of bituminous coal, etc., and achieve gas-solid reaction High efficiency, improved effect and stability, improved oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

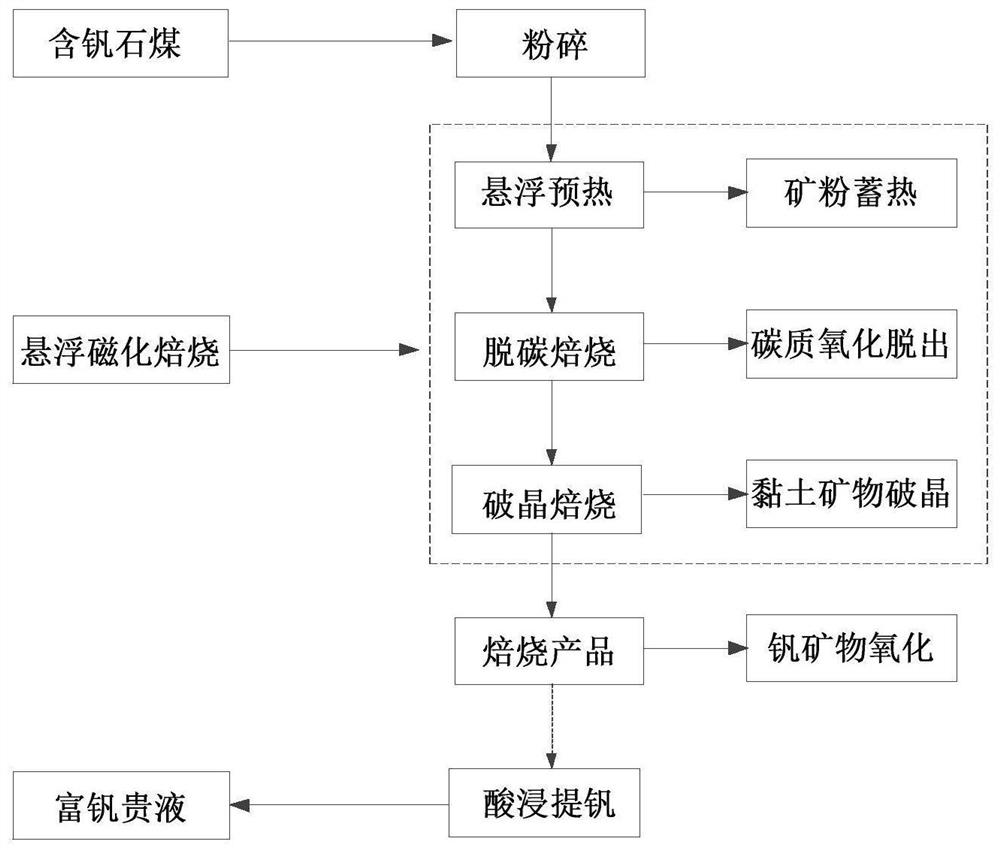

[0042] Process such as figure 1 shown;

[0043] The vanadium-containing stone coal block contains V by mass percentage 2 o 5 1.21%, C 11.87%, TFe 2.69%, SiO 258.33%; crush the vanadium-containing stone coal block with a particle size of 10-200mm to 2-10mm to make stone coal ore particles; grind the stone coal ore particles to -0.074mm with a mass content of 60% to make stone coal ore powder ;

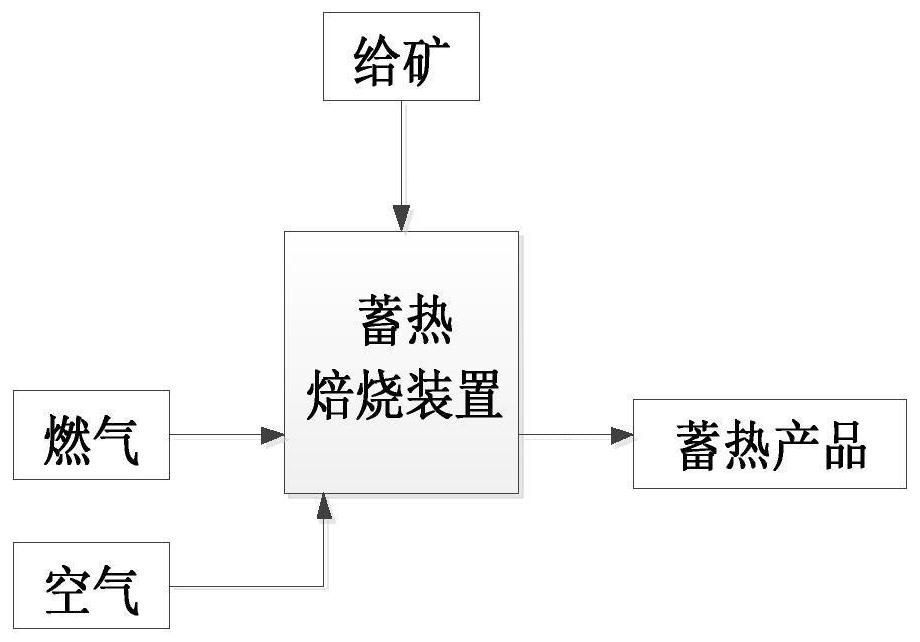

[0044] A suspension roasting device with a combustion station at the bottom and an induced draft fan on the top is adopted; when the induced draft fan is turned on, air and gas are introduced into the combustion station for combustion to generate hot flue gas, which then enters the suspension roasting device; at the same time, the stone coal mine The powder is transported to the suspension roasting device, and the stone coal ore powder enters from the upper part of the suspension roasting device; the stone coal ore powder is in a suspended state under negative pressure under the ac...

Embodiment 2

[0049] Method is with embodiment 1, and difference is:

[0050] (1) Vanadium-containing stone coal blocks contain V by mass percentage 2 o 5 0.95%, C 17.17%, TFe 6.51%, SiO 2 52.13%; the mass content of the part that grinds stone coal ore particles to -0.074mm is 80%;

[0051] (2) Stone coal powder is roasted at 800°C with heat storage; the residence time of stone coal powder in the suspension roasting device is 60s;

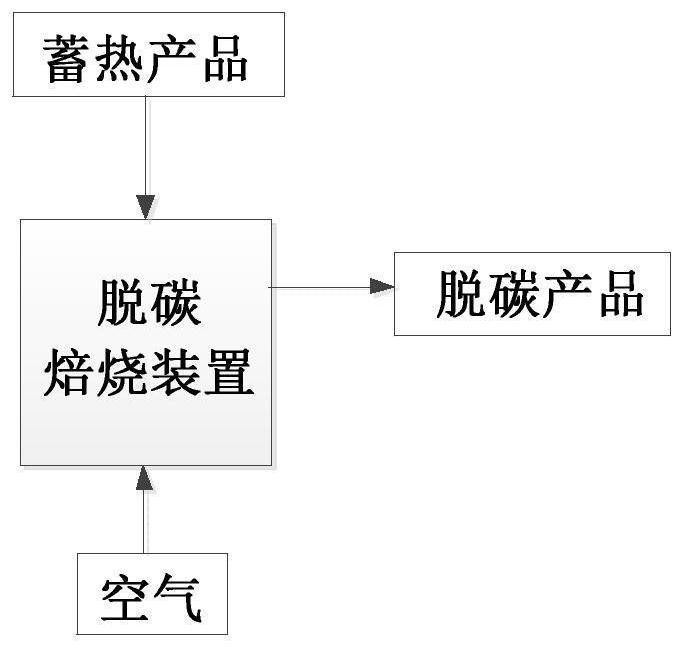

[0052] (3) The regenerative stone coal powder is decarburized and roasted at a temperature of 600°C, and the residence time in the decarburized roasting device is 26 minutes;

[0053] (4) In the mixed gas introduced in the crystal-breaking roasting device, the volume ratio of air and nitrogen is 2.5, the temperature of the decarburized material is controlled at 800°C, and the residence time of the decarburized material in the crystal-breaking roasting device is 50min;

[0054] (5) When acid leaching, the mass concentration of sulfuric acid solution is 30%, ...

Embodiment 3

[0056] Method is with embodiment 1, and difference is:

[0057] (1) Vanadium-containing stone coal blocks contain V by mass percentage 2 o 5 1.1%, C 13.2%, TFe 3.4%, SiO 2 54.6%; the mass content of the part that grinds stone coal ore particles to -0.038mm is 90% to make stone coal ore powder;

[0058] (2) Thermal storage roasting of stone coal powder at 850°C; the residence time of stone coal powder in the suspension roasting device is 40s;

[0059] (3) The regenerative stone coal powder is decarburized and roasted at a temperature of 850°C, and the residence time in the decarburized roasting device is 22 minutes;

[0060] (4) In the mixed gas introduced in the crystal-breaking roasting device, the volume ratio of air and nitrogen is 2.5, the temperature of the decarburized material is controlled at 850°C, and the residence time of the decarburized material in the crystal-breaking roasting device is 40min;

[0061] (5) When acid leaching, the mass concentration of sulfur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com