A mechanical and chemical coupling method for activating refractory iron ore pellets for energy saving and emission reduction

A technology for energy saving, emission reduction, iron ore, applied in the field of pretreatment of refractory iron ore, can solve the problems of poor roasting performance of refractory iron ore, reduce pellet energy consumption, promote consolidation reaction, increase specific surface area and activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

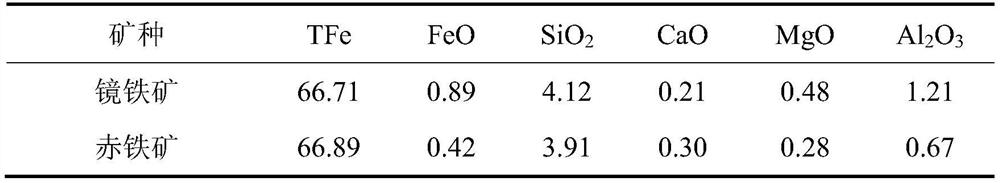

Embodiment 1

[0031] For the specularite in Table 1, adding 1.0% CaO content to the specularite is 54.2% limestone, the content of limestone less than 0.045mm is 80%, the content less than 0.02mm is 33%, and the moisture of limestone is controlled at 7.5%, after the limestone is added to the specularite, it is mixed with a horizontal strong mixer with coulter-type stirring blades, the stirring speed is 4r / min, and then high-pressure roller milling under the conditions of 2.5MPa and 7.5% moisture, The grate-rotary kiln is used for roasting, the temperature rise rate of the grate preheating stage I is controlled to be 100°C / min, and the decomposition ratio of limestone before entering the roasting reaches 90%. Compared with the conventional pellet preparation and sintering process of Example 1, the optimal pellet calcination temperature can be reduced to 1260°C, the pellet strength can be increased to 2678N / piece, the energy consumption can be reduced by 19%, and the SO 2 22% reduction in emi...

Embodiment 2

[0033]For the specularite in table 1, adding 1.5% CaO content to the specularite is 54.2% limestone, the content of limestone less than 0.045mm is 80%, the content less than 0.02mm is 33%, and the moisture of limestone is controlled at 7.0%, after the limestone is added to the specular iron ore, it is mixed with a horizontal strong mixer with a plow-type stirring blade at a stirring speed of 6r / min, and then high-pressure roller milled under the conditions of 3.2MPa and 7.0% moisture The grate-rotary kiln is used for roasting, the temperature rise rate of the grate preheating stage I is controlled to be 70°C / min, and the decomposition ratio of limestone before entering the roasting reaches 93%. Compared with the conventional pellet preparation and sintering process of Example 1, the optimal pellet calcination temperature can be reduced to 1240°C, the pellet strength can be increased to 2712N / piece, the energy consumption can be reduced by 25%, and the SO 2 30% reduction in emi...

Embodiment 3

[0035] For the hematite in Table 1, add 0.5% CaO to the hematite and add limestone with a content of 54.2%. The content of limestone less than 0.045mm is 80%, and the content less than 0.02mm is 33%. The moisture content of limestone is controlled at 7.0%, after limestone is added to the hematite, it is mixed with a horizontal strong mixer with coulter-type stirring blades, the stirring speed is 5r / min, and then high-pressure roller milling under the conditions of 2.5MPa and moisture 6.5%. The grate-rotary kiln is used for roasting, the temperature rise rate of the grate preheating stage I is controlled to be 85°C / min, and the decomposition ratio of limestone before entering the roasting reaches 92%. Compared with the conventional pellet preparation and sintering process of Example 1, the optimal pellet calcination temperature can be reduced from 1320°C to 1260°C, the strength of pellets can be increased from 2521N / piece to 2895N / piece, and the energy consumption can be reduced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com