A kind of self-healing lubricating grease and preparation method thereof

A lubricating grease and self-healing technology, applied in lubricating compositions, petroleum industry, additives, etc., can solve the problems of no self-repairing technology, complicated preparation process, expensive raw materials, etc., to extend the machine overhaul period, improve performance, The effect of improving the carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

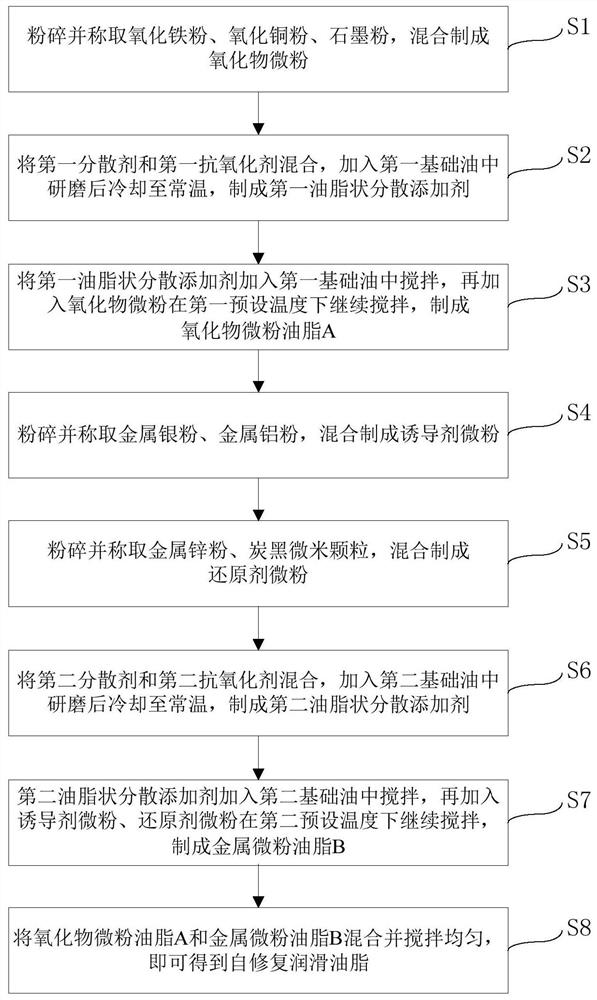

Image

Examples

Embodiment 1

[0042] Step 1. Oxide Micropowder Grease A:

[0043] Crush and sieve the iron oxide powder, screen out 5.8 grams of components of 1-100 μm, mix with 0.1 g of copper oxide powder crushed into the same particle diameter of 1-100 μm, add 0.1 g of graphite nanoparticles crushed into 0.05-10 μm, and mix Additives into 6 grams of powder.

[0044] Mix 0.5 g of succinimide and 3.5 g of p-diisooctyl diphenylamine, add it to 16 g of HVIWH150 base oil, grind it on a high-energy grinder for 2-4 hours to make a grease-like dispersing additive, and cool it to room temperature.

[0045] Add 20 grams of oil-like dispersing additives to 51 grams of HVIWH150 base oil and stir thoroughly, then slowly add 6 grams of powder additives and mix evenly, mix at 40-60 ° C, and mechanically stir for 1.5 hours. Make 77 grams of oxidant micropowder grease A.

[0046] Step 2, metal powder grease B:

[0047]Metal silver and metal aluminum are pulverized, sieved to obtain components with a particle diameter...

Embodiment 2

[0054] Step 1. Oxide Micropowder Grease A:

[0055] Crush and sieve the iron oxide powder, screen out 10 grams of components of 1-100 μm, mix with 1 gram of copper oxide powder crushed into the same particle diameter of 1-100 μm, add 1 gram of graphite nanoparticles crushed into 0.05-10 μm, and mix into 12 grams of powdered additives.

[0056] Mix 5 grams of succinimide and 16 grams of p-diisooctyl diphenylamine, add it to 30 grams of HVIWH300 base oil, grind it on a high-energy grinder for 2-4 hours to make a grease-like dispersing additive, and cool it to room temperature.

[0057] Add 51 grams of oil-like dispersing additives to 60 grams of HVIWH300 base oil and stir thoroughly, then slowly add 12 grams of powder additives and mix evenly, mix and mechanically stir at 40-60°C for 1.5 hours. Make 123 grams of oxidizing agent micropowder grease A.

[0058] Step 2, metal powder grease B:

[0059] Metal silver and metal aluminum are pulverized, sieved to obtain components wit...

Embodiment 3

[0066] Step 1. Oxide Micropowder Grease A:

[0067] Crush and sieve the iron oxide powder, screen out 7 grams of components of 1-100 μm, mix with 0.5 grams of copper oxide powder crushed into the same particle diameter of 1-100 μm, add 0.5 grams of graphite nanoparticles crushed into 0.05-10 μm, and mix Additives into 8 grams of powder.

[0068] Mix 1 gram of succinimide and 5 grams of p-diisooctyl diphenylamine, add it to 16 grams of HVIWH150 base oil, and grind it on a high-energy grinder for 2-4 hours to make a grease-like dispersing additive, and cool it to room temperature.

[0069] Add 22 grams of oil-like dispersing additives to 70 grams of HVIWH150 base oil and stir thoroughly, then slowly add 8 grams of powder additives and mix evenly, mix at 40-60 ° C, and mechanically stir for 1.5 hours. Make 100 grams of oxidant micropowder grease A.

[0070] Step 2, metal powder grease B:

[0071] Metal silver and metal aluminum are pulverized, sieved to obtain components with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com