Twin-tower type flue gas deep purification device through plasma coupling and sodium based absorption and method thereof

A technology of deep purification of flue gas and plasma, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, and can solve problems such as the inability to effectively remove elemental mercury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

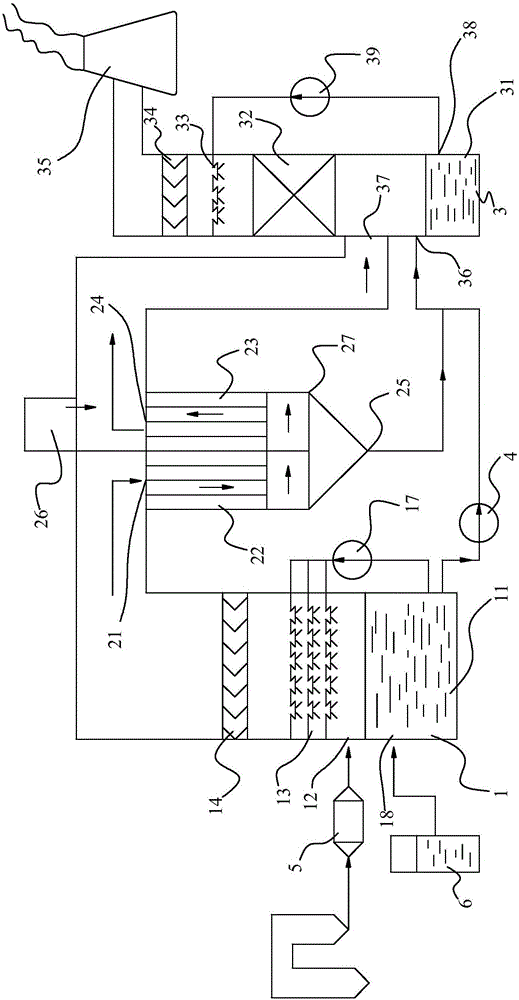

[0066] Embodiment 1, figure 1 A double-tower plasma-coupled sodium-based absorption flue gas deep purification device and method is given, including a desulfurization tower 1, a plasma demisting and oxidation device 2, and a denitrification and demercuration tower 3.

[0067] The present invention adopts the setting that the desulfurization tower 1 and the denitrification and mercury removal tower 3 are separated from each other; the mode of this separation setting firstly reduces the mutual competition between desulfurization and denitrification, and improves the desulfurization effect; secondly, after desulfurization, NOx and Hg are oxidized out, and there is help to improve the oxidation efficiency; finally according to the SO 2, NOx and Hg chemical characteristics, and carry out the targeted design of the absorption tower.

[0068] The desulfurization tower 1 includes a desulfurization slurry circulation pool 11 , a desulfurization flue gas inlet 12 , a desulfurization sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com