Preparation of demulsifier for rapidly dehydrating crude oil of offshore platform

A rapid dehydration, offshore platform technology, used in chemical dehydration/demulsification, petroleum industry, processing hydrocarbon oil, etc., can solve the problems of difficult destruction, reduced oil production, etc., and achieve low cost, good effect, high surface active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

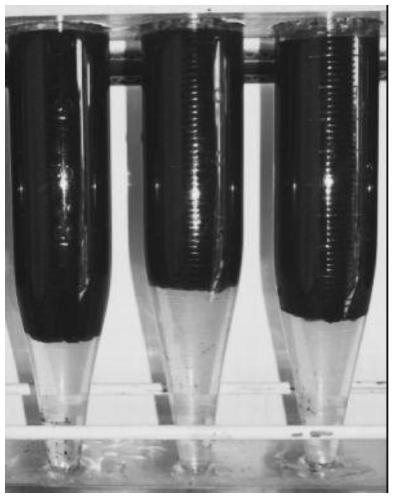

Image

Examples

Embodiment 1

[0046] (1) Add 20g of bisphenol A and 50g of triethylenetetramine into a four-necked bottle, stir and raise the temperature in a water bath to 50°C for 15 minutes, then slowly add 62.5g of 40% formaldehyde solution dropwise, and keep it warm for 30 minutes after the dropwise addition, then add 66.25 g xylene, after heating up to 105°C, carry out reflux dehydration, and then gradually raise the temperature to 190°C after 2 hours. At this time, the transparency of the reactant and xylene gradually increases, and the xylene is completely distilled at 190°C. Keep the reaction for 1 hour to complete the reaction. The product is dark red viscous liquid, and the initiator is obtained;

[0047] (2) Get 4g of starter and 15.84g of potassium hydroxide and put it into the reactor, and seal the reactor. Use nitrogen to purge and replace the air, then use a vacuum pump to evacuate, start heating after 5 minutes, stop heating when the temperature rises to 110°C, open the feed valve, feed 13...

Embodiment 1

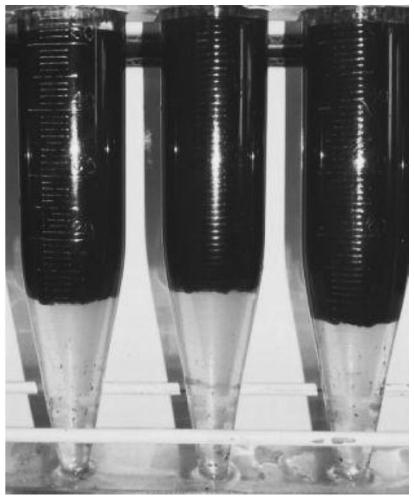

[0051] In Example 1, the mass ratio of initiator, ethylene oxide, and propylene oxide was changed to 1:53:106 to obtain polyether A2, and modified to obtain modified demulsifier sample 2.

[0052] (1) Add 20g of bisphenol A and 50g of triethylenetetramine into a four-necked bottle, stir and raise the temperature in a water bath to 50°C for 15 minutes, then slowly add 62.5g of 40% formaldehyde solution dropwise, and keep it warm for 30 minutes after the dropwise addition, then add 66.25 g xylene, after heating up to 105°C, carry out reflux dehydration, and then gradually raise the temperature to 190°C after 2 hours. At this time, the transparency of the reactant and xylene gradually increases, and the xylene is completely distilled at 190°C. Keep the reaction for 1 hour to complete the reaction. The product is dark red viscous liquid, and the initiator is obtained;

[0053] (2) Get 4g of starter and 15.84g of potassium hydroxide and put it into the reactor, and seal the reactor...

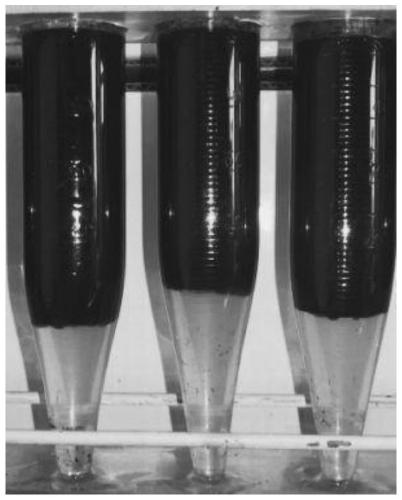

Embodiment 3

[0057] In Example 1, the mass ratio of initiator, ethylene oxide, and propylene oxide was changed to 1:66:132 to obtain polyether A3, and modified to obtain modified demulsifier sample 3.

[0058] (1) Add 20g of bisphenol A and 50g of triethylenetetramine into a four-necked bottle, stir and raise the temperature in a water bath to 50°C for 15 minutes, then slowly add 62.5g of 40% formaldehyde solution dropwise, and keep it warm for 30 minutes after the dropwise addition, then add 66.25 g xylene, after heating up to 105°C, carry out reflux dehydration, and then gradually raise the temperature to 190°C after 2 hours. At this time, the transparency of the reactant and xylene gradually increases, and the xylene is completely distilled at 190°C. Keep the reaction for 1 hour to complete the reaction. The product is dark red viscous liquid, and the initiator is obtained;

[0059] (2) Get 4g of starter and 15.84g of potassium hydroxide and put it into the reactor, and seal the reactor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com