Offshore oil thermal recovery produced water treatment de-emulsifier and preparation method thereof

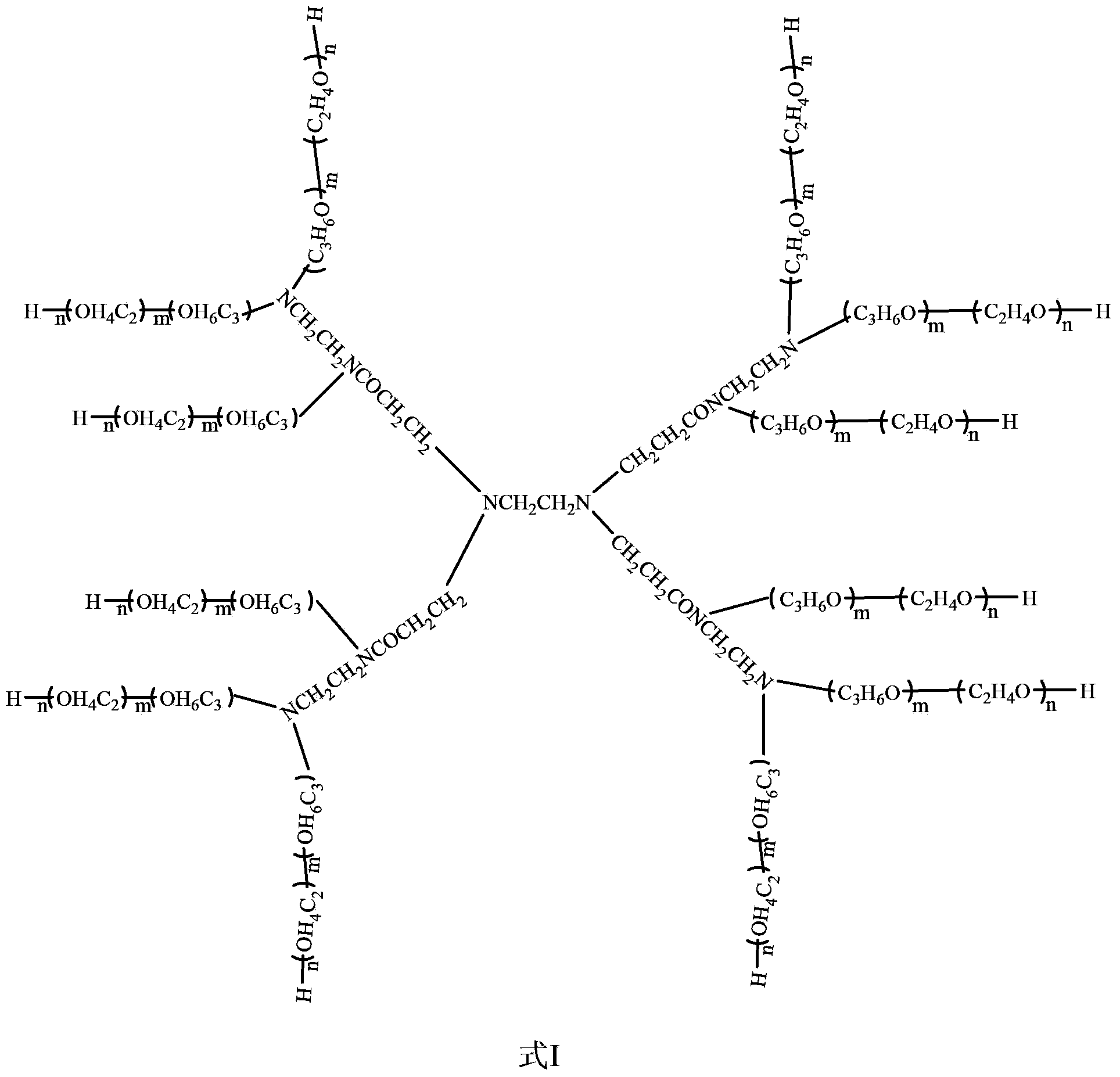

A technology of demulsifier and polyamide, which is applied in the field of demulsifier for thermal recovery and produced water treatment in offshore oil fields, can solve the problem of high synthesis cost, and achieve the effects of small dosage, good demulsification performance and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

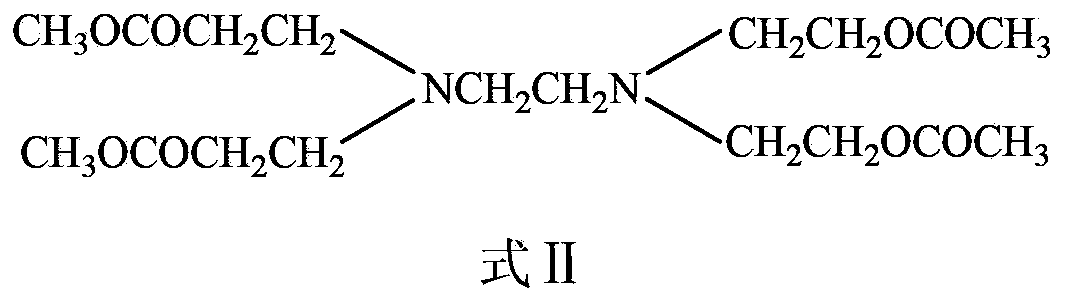

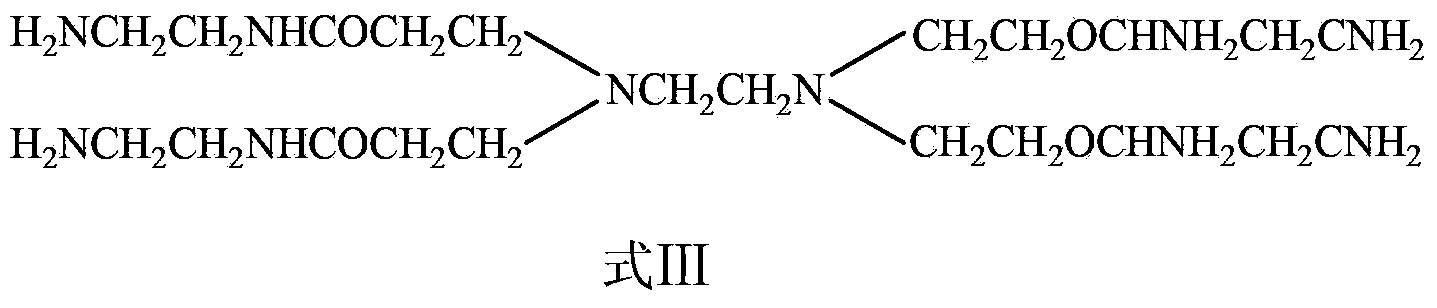

Method used

Image

Examples

Embodiment 1

[0030] Example 1. Synthesis of Demulsifier ZH-1

[0031] Propylene oxide with a polymerization number of 4 and ethylene oxide with a polymerization number of 4 are mixed for polymerization reaction to produce a propylene oxide ethylene oxide diblock polyether ZH-1.

Embodiment 2

[0032] Example 2. Synthesis of Demulsifier ZH-2

[0033] Propylene oxide with a polymerization number of 4 and ethylene oxide with a polymerization number of 9 are mixed for polymerization reaction to produce a propylene oxide ethylene oxide diblock polyether ZH-2.

Embodiment 3

[0034] Example 3. Synthesis of Demulsifier ZH-3

[0035] Propylene oxide with a polymerization number of 4 and ethylene oxide with a polymerization number of 13 are mixed and polymerized to produce a demulsifier model of propylene oxide ethylene oxide diblock polyether ZH-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dehydration rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com