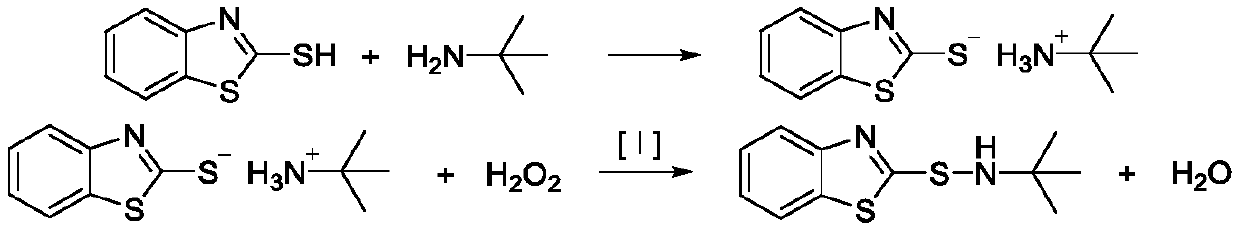

Process for preparing NS by oxidizing M tert-butyl ammonium salt with hydrogen peroxide

A technology of hydrogen peroxide and butylammonium salt, applied in organic chemistry and other directions, can solve the problems of difficult treatment of salt-containing organic wastewater, human and environmental hazards, difficult operation, etc. mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 167.25g of accelerator M to 109.71g of tert-butylamine and 20g of water for beating, raise the temperature to 30°C and stir to make all M and tert-butylamine combine to form a salt. After TLC detects that there is no free M, add 0.2g of KI, heat to 30°C, and add 156.4g dropwise Concentration of 27.5% hydrogen peroxide. Hydrogen peroxide was added dropwise for 10 min, and the reaction was incubated until no M tert-butylammonium salt remained in TLC detection. Cool down, centrifuge, wash, recover tert-butylamine, and dry the filter cake to obtain NS finished product. Initial melting point: 107.4°C, purity 98.6%, yield: 98.1%, product appearance is white particles.

Embodiment 2

[0035] Add 167.25g of accelerator M to 182.85g of tert-butylamine and 5g of water for beating, raise the temperature to 20°C and stir to make all M and tert-butylamine combine to form a salt. After TLC detects that there is no free M, add 0.01g of I 2 , the temperature was raised to 25° C., and then 156.4 g of hydrogen peroxide with a concentration of 27.5% was added, and the hydrogen peroxide was added dropwise for 10 min, and the temperature was kept until no M tert-butylammonium salt was left in TLC detection. Cool down, centrifuge, wash, recover tert-butylamine, and dry the filter cake to obtain NS finished product. Initial melting point: 107.2°C, purity 99.5%, yield: 98.2%, product appearance is white particles.

Embodiment 3

[0037] Add 167.25g of accelerator M to 167.1g of tert-butylamine and 10g of water for beating, raise the temperature to 30°C and stir to make all M and tert-butylamine combine to form a salt, and add 0.8g of KIO after TLC detects free M 3 , continue to maintain 30 ° C, and dropwise add 172.1 g of hydrogen peroxide with a concentration of 25.1%. Hydrogen peroxide was added dropwise for 30 minutes, and the reaction was incubated until no M tert-butylammonium salt remained in TLC detection. Cool down, centrifuge, wash, recover tert-butylamine, and dry the filter cake to obtain NS finished product. Initial melting point: 107.6°C, purity 99.2%, yield: 98.6%, product appearance is white particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com