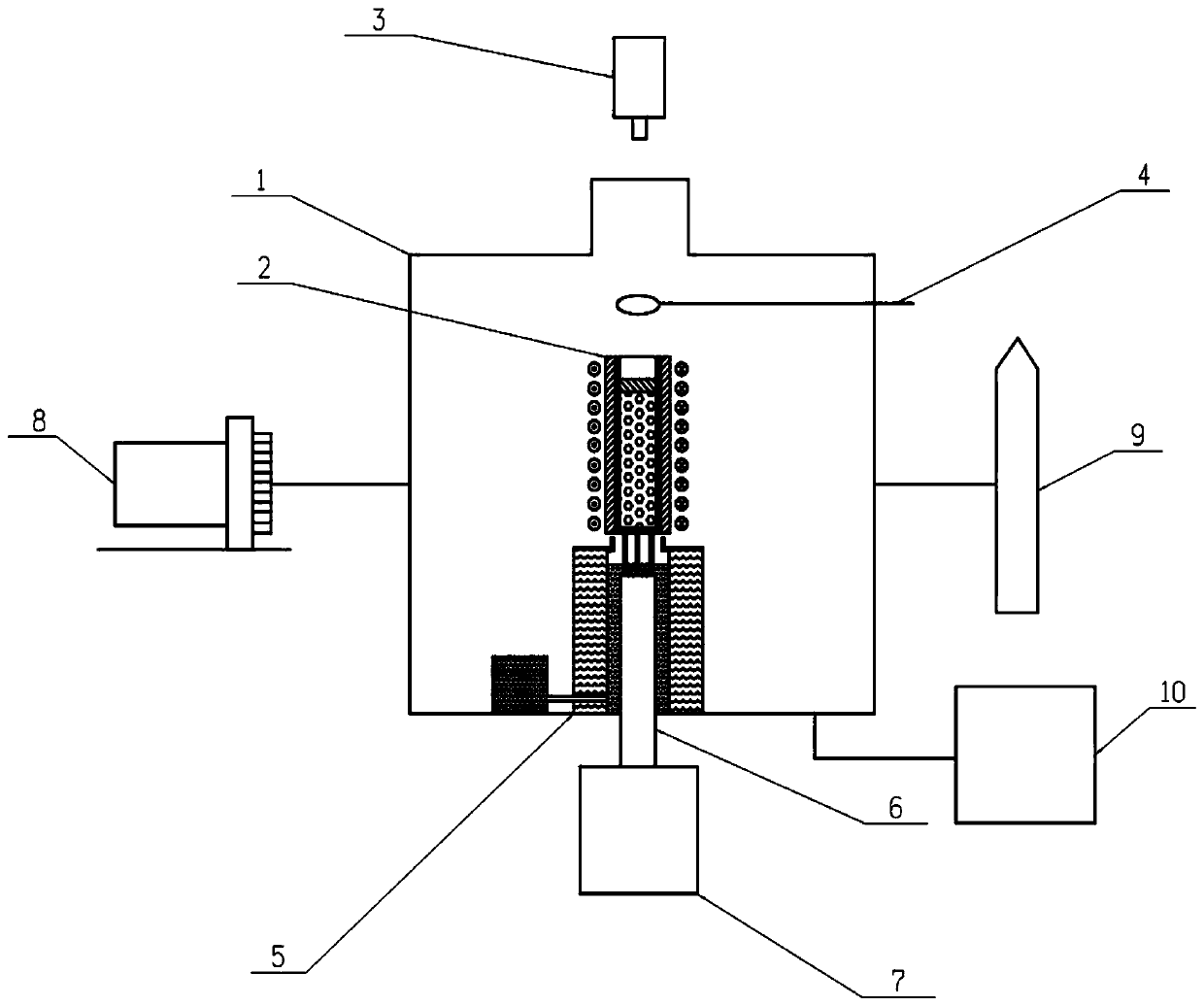

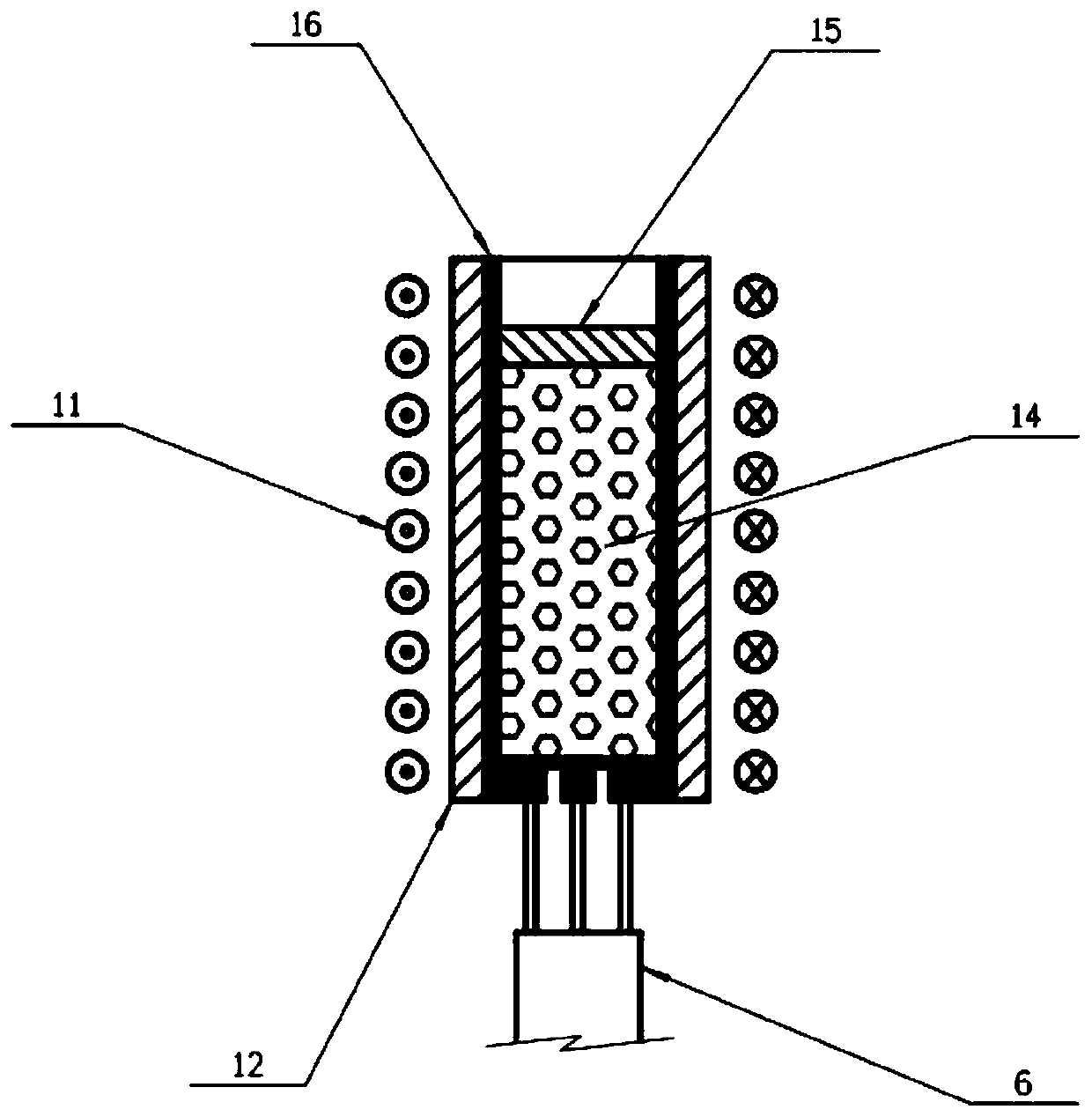

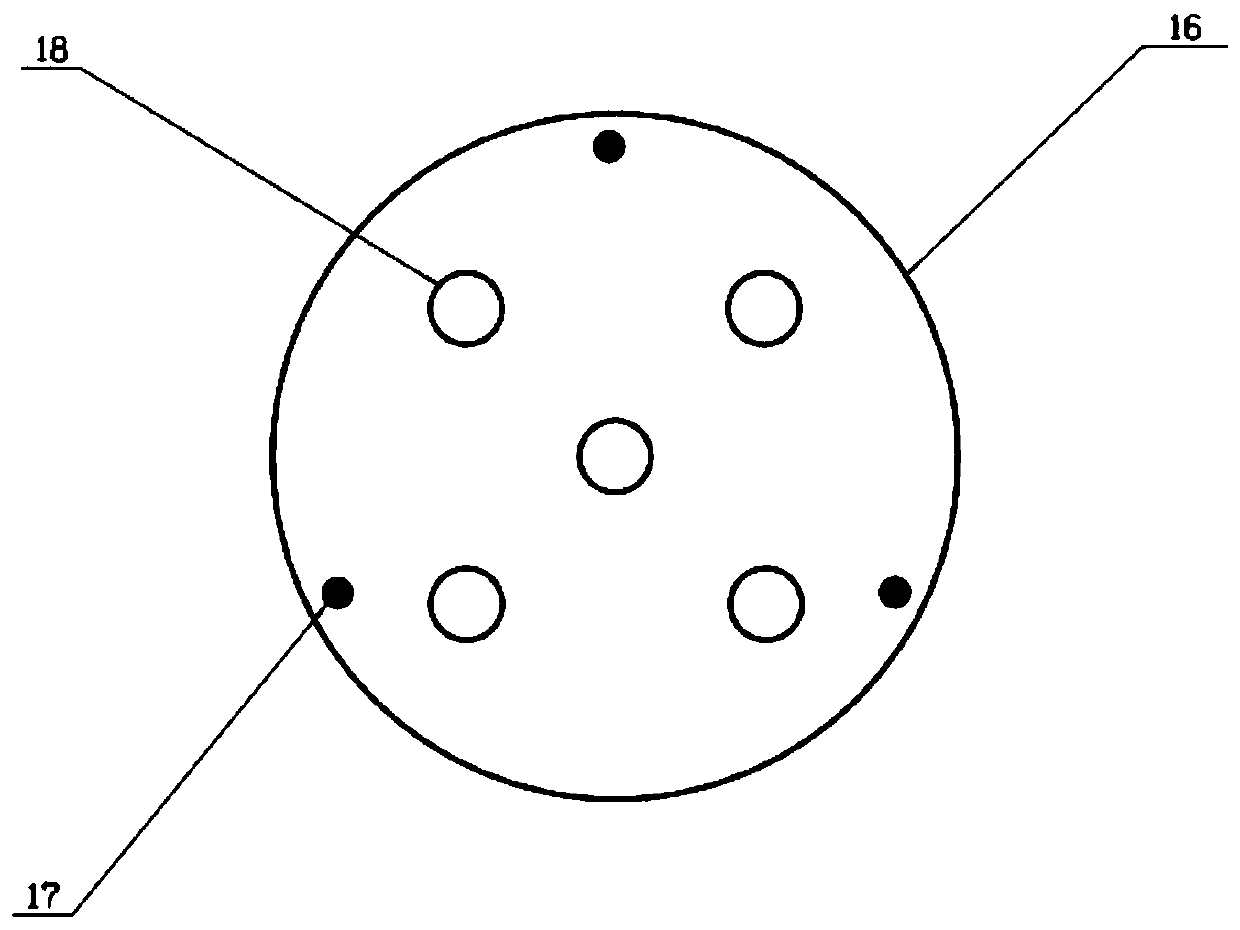

Multi-mode excitation deep supercooling directional solidification device and method

A technology of directional solidification and deep undercooling, applied in the direction of improving process efficiency, etc., can solve the problems of complicated processes, inability to perform in-situ melting and directional solidification, and single excitation method, so as to achieve sufficient melting, improve material utilization and production. The effect of less defects such as efficiency and shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] 1. Prepare 1kg of 302 stainless steel (1Cr18Ni9) alloy raw material and put it into the crucible; according to B 2 O 3 , Na 2 B 4 O 7 The ratio is 1:1 to prepare the glass cleaner and put it into the dosing spoon.

[0103] 2. Turn on the vacuum pump 8 to pump the sealed chamber to 1×10 -6 Pa, and then fill the sealed chamber with high-purity argon to 0.8×10 5 Pa, repeat this process five times. Start the smelting device 2 and increase the heating power, observe the melting of the alloy through the thermometer 3, and keep the temperature for 30 minutes after the alloy is completely melted.

[0104] 3. Add the glass purifying agent into the crucible through the feeding device 4, heat the sample to overheat 250K and keep it for 10 minutes, then turn off the power of the smelting device 2, and repeat the above steps five times after the sample is cooled to room temperature.

[0105] 4. When the alloy temperature drops to 50K subcooling, start the power supply of the ...

Embodiment 2

[0108] 1. Prepare 5kg of Monel K500 nickel-based alloy raw material and put it into the crucible; 2 O 3 Put the glass cleaner into the dosing spoon.

[0109] 2. Turn on the vacuum pump 8 to pump the sealed chamber to 1×10 -6 Pa, and then fill the sealed chamber with high-purity helium to 1×10 5 Pa, repeat this process three times. Start the smelting device 2 and increase the heating power, observe the melting of the metal through the thermometer 3, and keep the temperature for 30 minutes after the metal is completely melted.

[0110] 3. Add the glass purifying agent into the crucible through the feeding device 4, heat the sample to overheat 300K and keep it for 20 minutes, then turn off the power of the smelting device 2, and repeat the above steps six times after the sample is cooled to room temperature.

[0111] 4. When the alloy temperature drops to 230K subcooling degree, start the power supply of the pulling device 7, pull down the crucible at a rate of 1mm / s and just...

Embodiment 3

[0114] 1. Prepare 0.01kg of metal raw material according to the atomic ratio of Ti, Ni, Al, and Cr at 14:3:2:1 and put it into the crucible; according to SiO 2 , B 2 O 3 , CaO, Al 2 O 3 , Na 2 O, K 2 The ratio of O is 5:2:2:1:1:1 to prepare the glass cleaner and put it into the feeding spoon.

[0115] 2. Turn on the vacuum pump 8 to pump the sealed chamber to 1×10 -6 Pa, and then fill the sealed chamber with a mixture of high-purity helium and argon at a ratio of 1:3 to 0.5×10 5 Pa, repeat this process three times. Start the smelting device 2 and increase the heating power, observe the melting of the metal through the thermometer 3, and keep the temperature for 10 minutes after the metal is completely melted.

[0116] 3. Add the glass purifying agent into the crucible through the feeding device 4, heat the sample to overheat 100K and keep it for 5 minutes, then turn off the power of the smelting device 2, and repeat the above steps twice after the sample is cooled to r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com