Electrode silver paste for functional ceramics and preparation method of electrode silver paste

A technology of functional ceramics and electrodes, which is applied in the field of electrode silver paste for functional ceramics and its preparation, can solve the problems of affecting the carrier transmission of ceramic interfaces, the inability to guarantee the stability of devices in service, and the loss of wetting performance, etc., to improve the interface bonding strength , Inhibit diffusion erosion, reduce the effect of vitreous content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

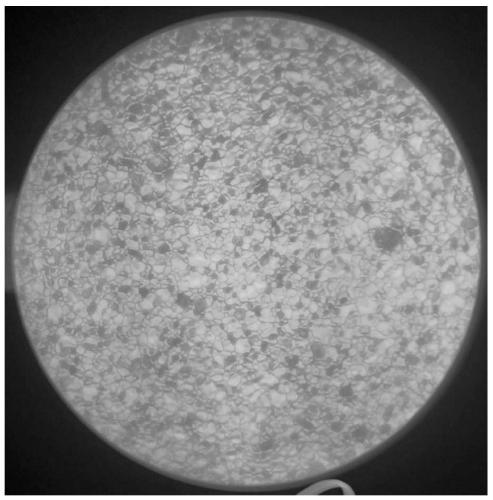

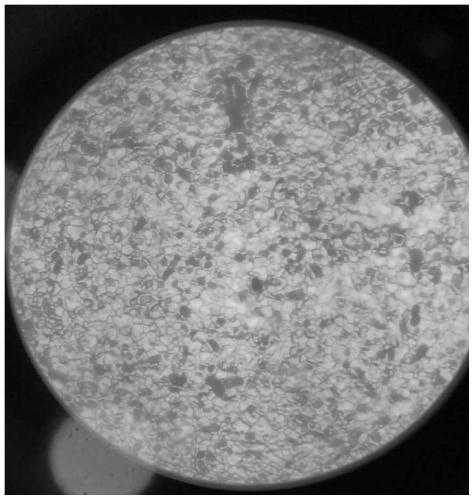

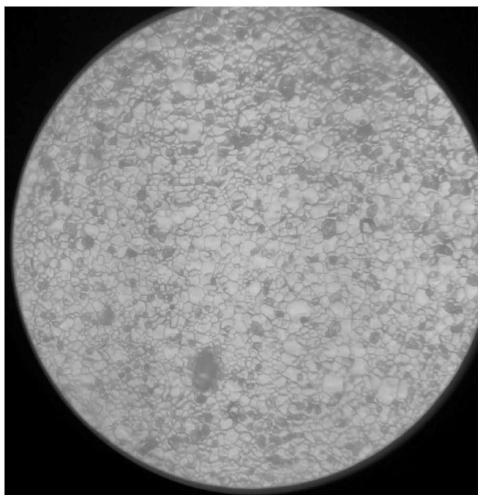

Image

Examples

Embodiment 1

[0034] An electrode silver paste for functional ceramics, which consists of the following raw material components in mass percentage: 85wt% silver-based mixture, 0.8wt% lead-free glass powder, 1wt% phase-forming compound, and 13.2wt% organic carrier;

[0035] Add 5wt% ethyl cellulose to 87wt% terpineol and butyl carbitol mixed solvent, its volume ratio V:V=l:3, stir at a constant temperature of 70°C until it dissolves completely, stir and cool to room temperature, add 8wt %lecithin, Span-85 and rosin mass ratio W:W:W=1:1:0.5, dispersed at high speed for 15 minutes, and ultrasonically filtered to obtain a uniformly dispersed organic vehicle.

[0036] Weigh the raw materials according to the following mass percentage: the range of 20wt% flake silver powder has a tap density of 4.0g / cm 3 , DMAX≤5μm, burning loss≤1%, specific surface area 0.7m 2 / g, the range of 60wt% spherical silver powder tap density 4.7g / cm 3 , average particle size 3.0μm, burning loss ≤ 1%, specific surface...

Embodiment 2

[0040] An electrode silver paste for functional ceramics, comprising the following components in mass percentage:

[0041] 76wt% silver mixture, 1.8wt% lead-free glass powder, 0.2wt% phase-forming compound, 22wt% organic vehicle.

[0042] 6wt% ethyl cellulose and phenolic resin mass ratio W:W=5:1 are added in 90wt% terpineol and butyl carbitol mixed solvent, its volume ratio V:V=3:l, constant temperature 70 ℃ Stir until it is completely dissolved, stir and cool to room temperature, add 4wt% lecithin, castor oil and organic wax at a mass ratio of W:W:W=1:1:0.5, disperse at high speed for 15 minutes, and ultrasonically filter to obtain a uniformly dispersed organic vehicle .

[0043] Weigh raw materials according to the following mass percentage: 70wt% spherical silver powder, tap density 4.5g / cm 3 , average particle size 2.8μm, specific surface area 1.0m 2 / g, 6wt% silver carbonate, 1.8wt% lead-free glass softening point 610°C, average particle size 2 O, 22 wt% organic vehic...

Embodiment 3

[0047] An electrode silver paste for functional ceramics, which consists of the following raw material components in mass percentage: 65wt% silver-based mixture, 1.2wt% lead-free glass powder, 0.5wt% phase-forming compound, and 33.3wt% organic carrier;

[0048] Add 8wt% ethyl cellulose to 89wt% butyl carbitol and DBE mixed solvent, its volume ratio V:V=2:l, stir at a constant temperature of 70°C until it dissolves completely, stir and cool to room temperature, add 3wt% lecithin , castor oil and sodium hexametaphosphate mass ratio W:W:W=2:1:1, disperse 15min under the high rotating speed, and obtain the evenly dispersed organic carrier by ultrasonic filtration, take raw material by the following mass percentage:

[0049] The range of 14wt% flake silver powder Tap density 1.4g / cm 3 , DMAX≤10μm, burning loss≤1%, specific surface area 1.5m 2 / g; 44wt% range of spherical silver powder tap density 3.7g / cm 3 , average particle size 1.7μm, burning loss ≤ 1%, specific surface area 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com