Microwave preparation method of cross-linked polymer based on beta-cyclodextrin

A technology of cross-linked polymer and cyclodextrin, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of waste of raw materials, long reaction time, uneven heating, etc., achieve wide application prospects, shorten reaction time, improve Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

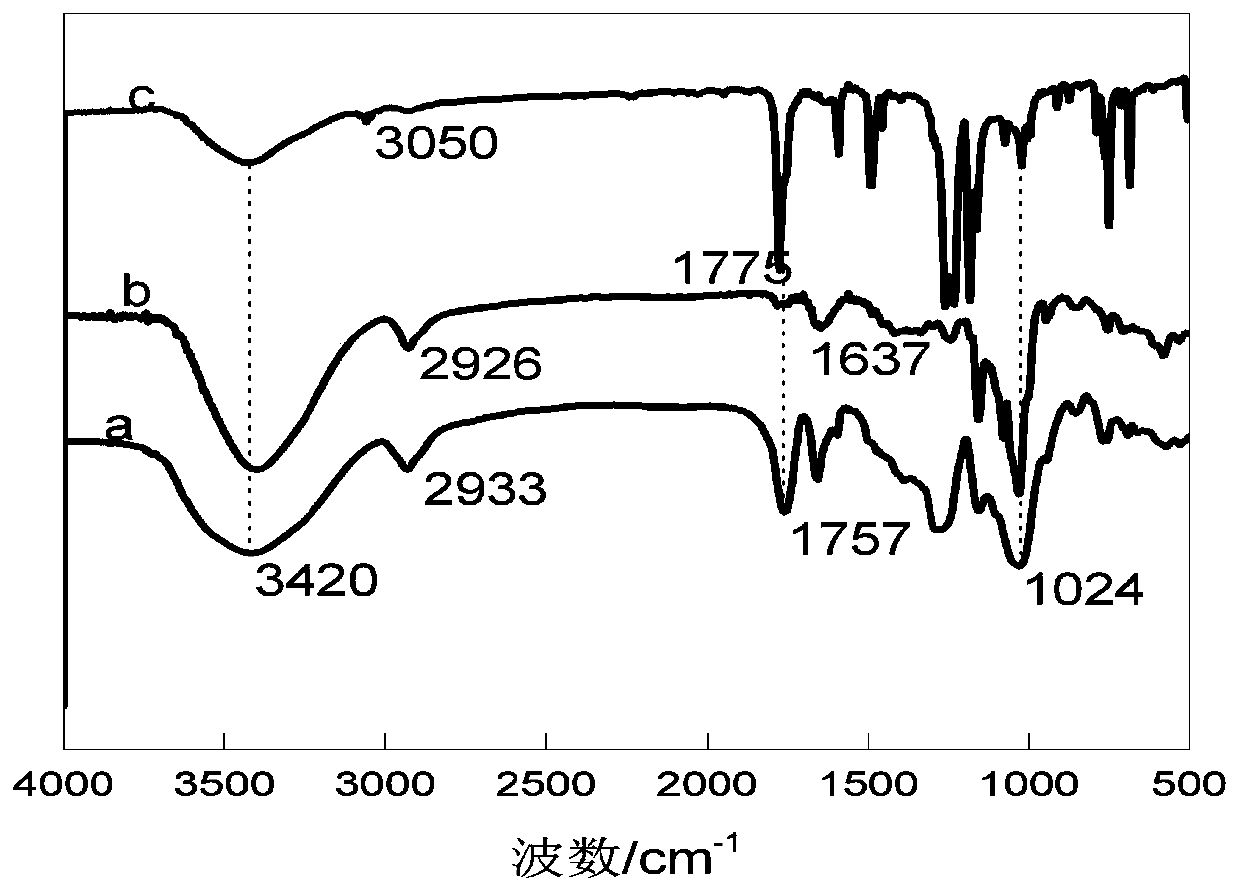

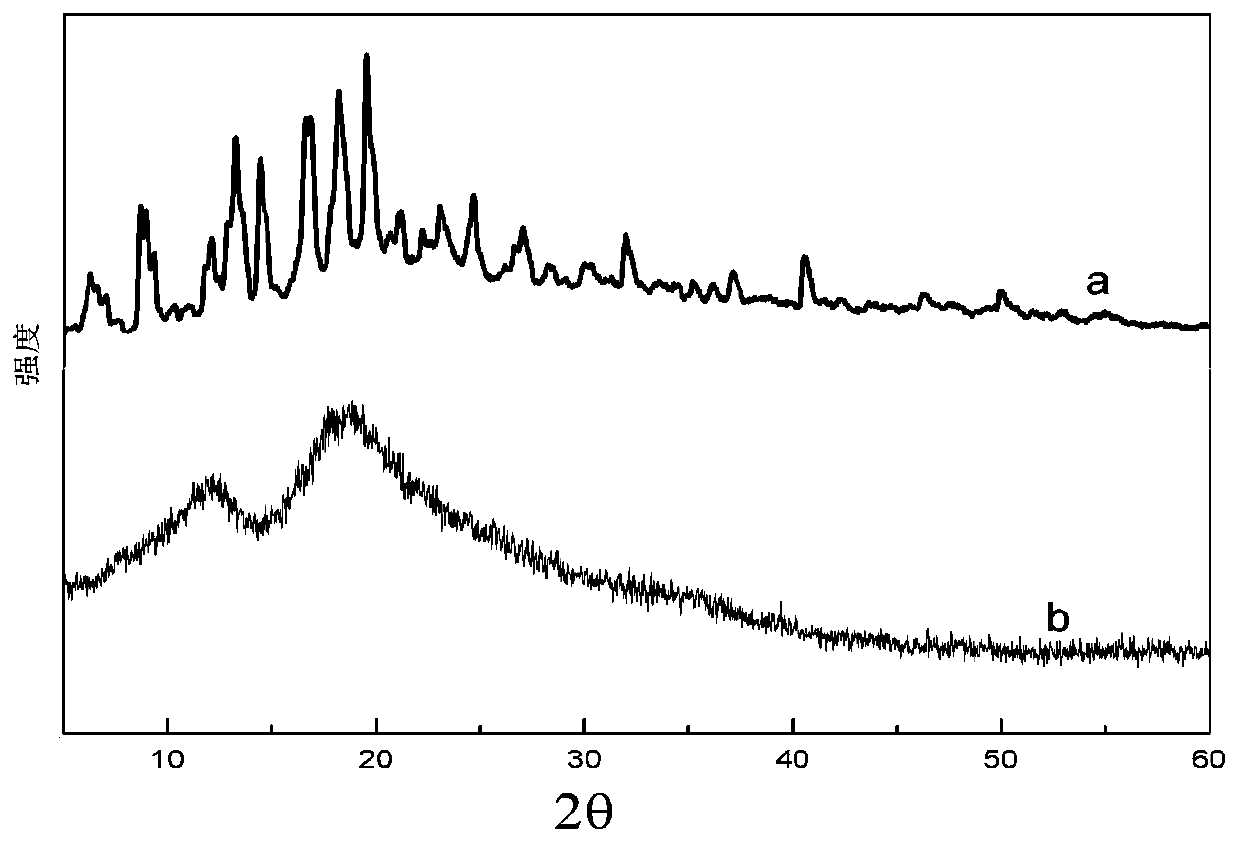

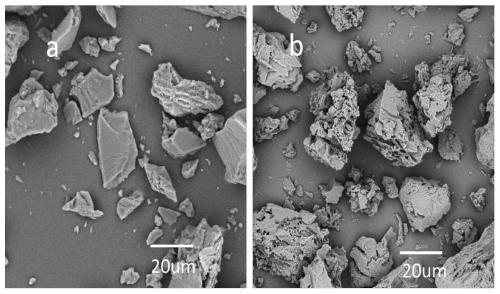

[0027] A microwave preparation method of a cross-linked polymer based on β-cyclodextrin, comprising the following steps:

[0028] (1) Stir β-cyclodextrin (β-CD, 4.548g, 0.004mol) and solvent N,N-dimethylformamide (DMF, 54g) evenly, add catalyst triethylamine (TEA, 1.7mL, 0.012mol), microwave reaction for 20min at a reaction temperature of 90°C and a microwave power of 800W;

[0029] (2) Add the crosslinking agent diphenyl carbonate (DPC, 6.000g, 0.028mol) to the reaction solution obtained in step (1), and then microwave the reaction for 90min under the condition that the reaction temperature is 90°C and the microwave power is 800W, Cool to room temperature;

[0030] (3) the reaction solution that step (2) is obtained is transferred to the deionized water equivalent to 6 volume times of the reaction solution that step (2) obtains, is 900r / min stirring and dispersing at speed, separates out white gel-like solid, in Centrifuge at 3000r / min for 8min, vacuum filter, wash the soli...

Embodiment 2

[0045] A microwave preparation method of a cross-linked polymer based on β-cyclodextrin, comprising the following steps:

[0046] (1) Stir β-cyclodextrin (4.548g, 0.004mol) and solvent N,N-dimethylformamide (22.74g) evenly, add catalyst triethylamine (0.6mL, 0.004mol), at reaction temperature Microwave reaction for 30 minutes at 80°C and microwave power of 400W;

[0047] (2) Add cross-linking agent diphenyl carbonate (3.424g, 0.016mol) to the reaction solution obtained in step (1), then microwave reaction for 120min at a reaction temperature of 80°C and a microwave power of 400W, and cool to room temperature;

[0048] (3) The reaction solution obtained by step (2) is transferred to deionized water equivalent to 5 volume times of the reaction solution obtained by step (2), stirred and dispersed at 600r / min, and a white gel-like solid is separated out. Centrifuge for 10 min, filter with suction, wash the solid in batches with 40 mL of deionized water to remove unreacted β-CD a...

Embodiment 3

[0052] A microwave preparation method of a cross-linked polymer based on β-cyclodextrin, comprising the following steps:

[0053] (1) Stir β-cyclodextrin (3.405g, 0.003mol) with solvent N,N-dimethylformamide (40.86g), add catalyst triethylamine (2mL, 0.015mol), and the reaction temperature is Microwave reaction for 10 minutes at 100°C and microwave power of 1000W;

[0054] (2) Add the cross-linking agent diphenyl carbonate (6.427g, 0.03mol) to the reaction solution obtained in step (1), then microwave reaction for 30min at a reaction temperature of 100°C and a microwave power of 1000W, and cool to room temperature;

[0055] (3) The reaction solution obtained in step (2) is transferred to deionized water equivalent to 8 volume times of the reaction solution obtained in step (2), stirred and dispersed at 1200r / min, and a white gelatinous solid is separated out at 3500r / min Centrifuge for 6 min, filter with suction, wash the solid in batches with 60 mL of deionized water to rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com