Green synthesis method of imidazoline under visible light catalysis

A green synthesis technology of imidazoline, applied in the direction of organic chemistry, can solve the problems of low efficiency, difficult to obtain raw materials, many synthesis steps, etc., and achieve the effect of easy to obtain raw materials, cheap raw materials, and green and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

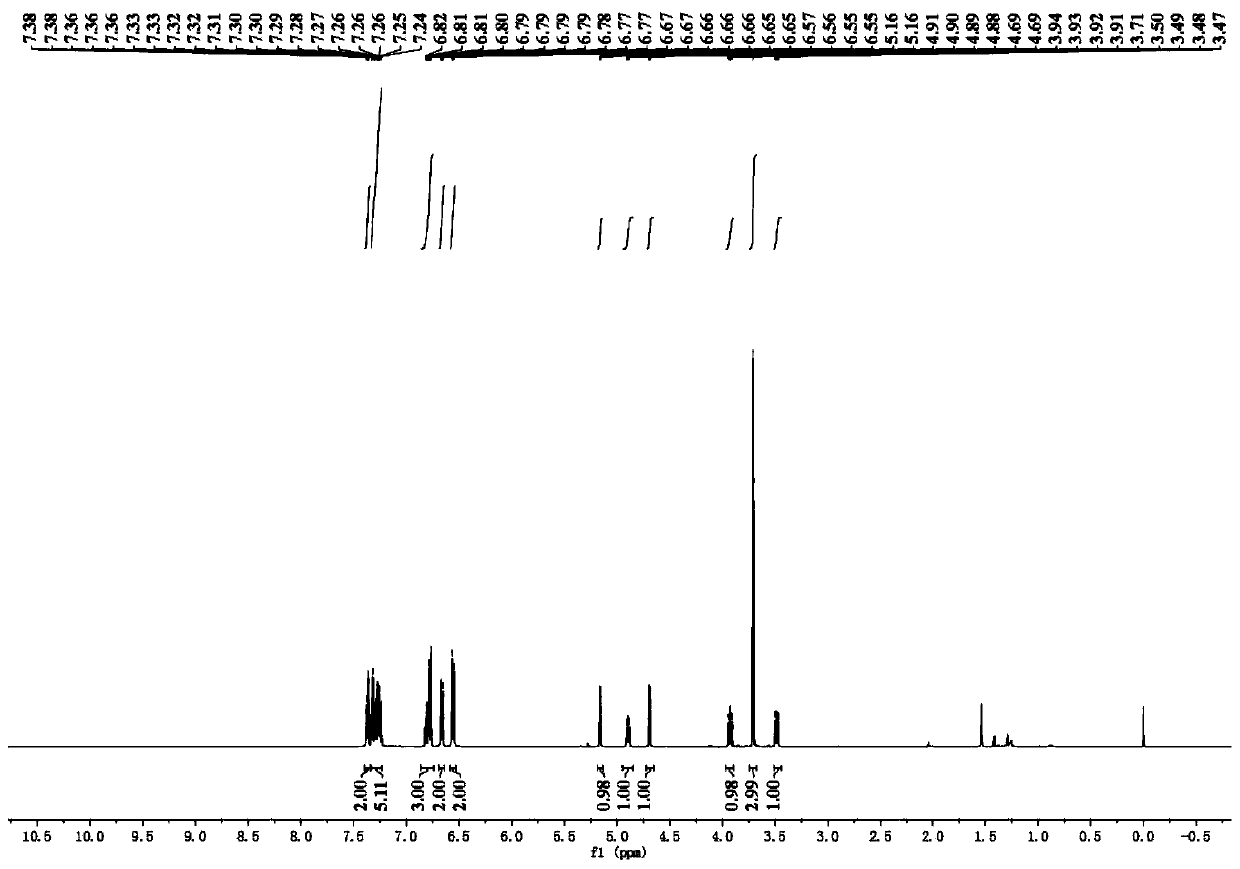

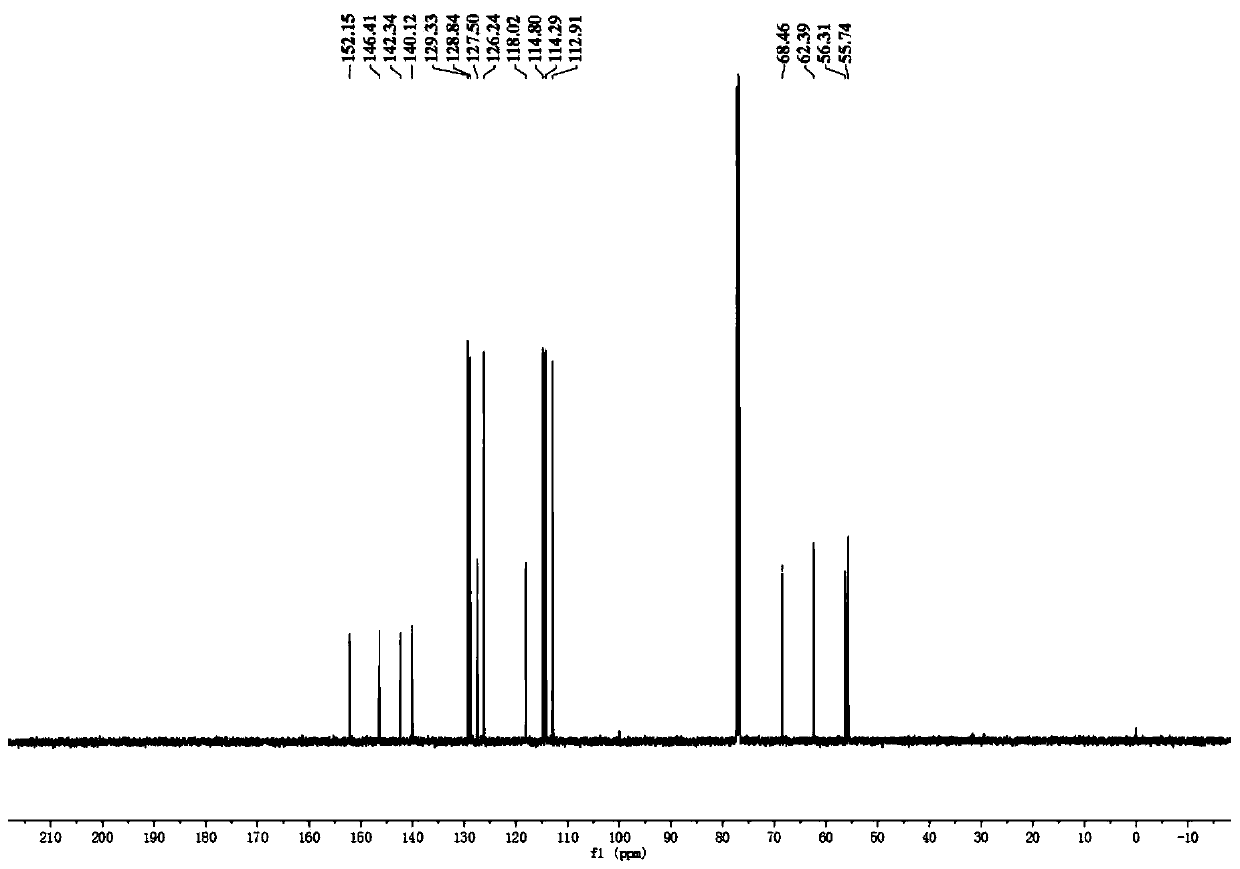

[0064] In a dry 10mL Schlenk tube, add 90.4mg N-phenylglycine, 24.7mg p-methoxyaniline, 2.6mg photocatalyst {Ir[dF(CF 3 )ppy] 2 bpy}PF 6 , 12.1mg oxidant Co(dmgH 2 ) 2 PyCl, 2 mL of 1,2-dichloroethane, 21.2 mg of benzaldehyde, the ratio of benzaldehyde: p-methoxyaniline: N-phenylglycine: photocatalyst: oxidant is 1:1:3:0.01:0.15. The reaction bottle was pumped and ventilated three times to ensure that the reaction tube was anhydrous and oxygen-free, then sealed, and the reaction was placed under 455nm blue light (Blue LED light) and stirred for 2 hours. The distance between the Blue LED light and the Schlenk tube was 3cm. After the TLC detection reaction was completed, the reaction solution was transferred to an eggplant-shaped bottle, an appropriate amount of silica gel was added to concentrate under reduced pressure, and the resulting residue was purified by column chromatography (PE / EA=100:1), as Figure 1-2 As shown, the synthesized product was 3-(4-methoxyphenyl)-1,4-...

Embodiment 2

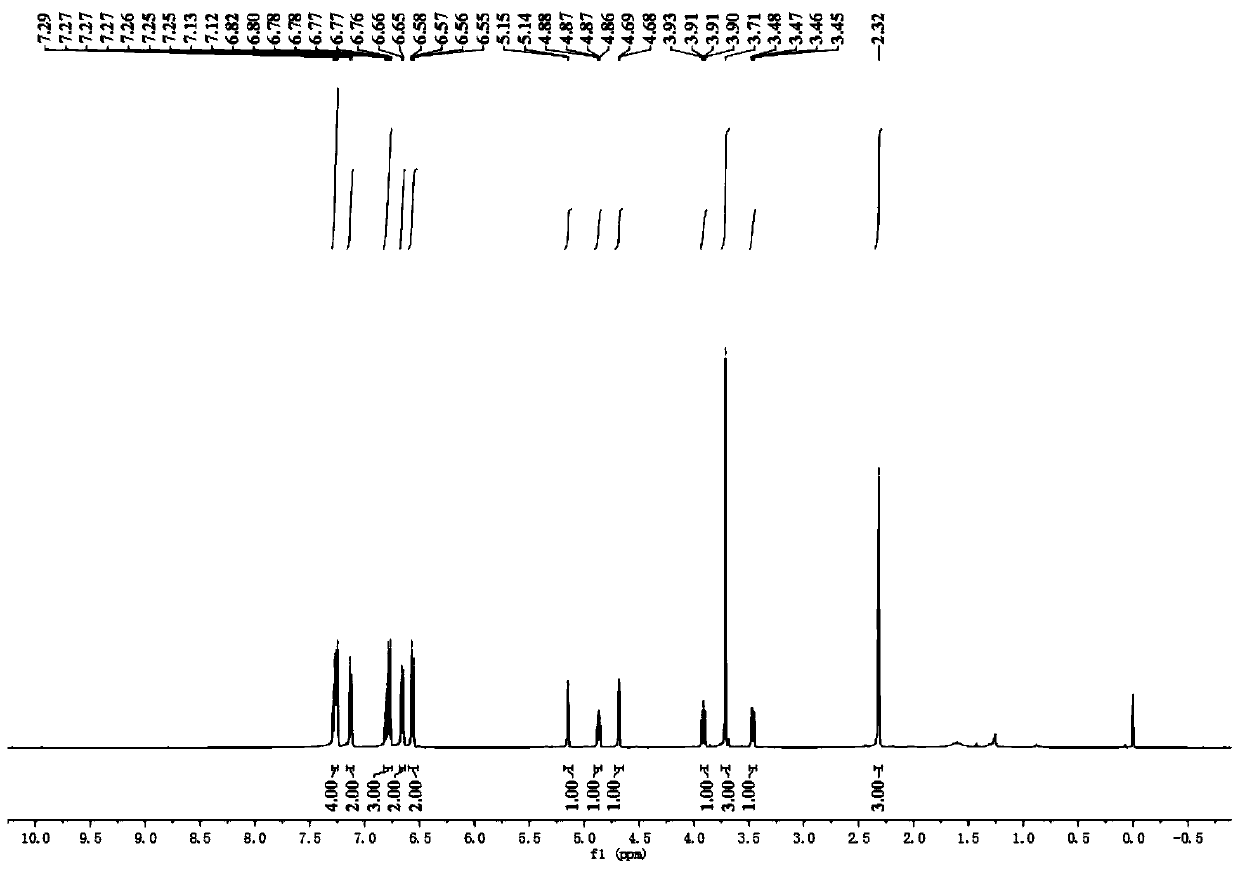

[0069] In a dry 10mL Schlenk tube, add 90.4mg N-phenylglycine, 24.7mg p-methoxyaniline, 2.6mg photocatalyst {Ir[dF(CF 3 )ppy] 2 bpy}PF 6 , 12.1mg oxidant Co(dmgH 2 ) 2 PyCl, 2mL1,2-dichloroethane, 24.1mg p-tolualdehyde, p-tolualdehyde: p-methoxyaniline: N-phenylglycine: photocatalyst: the ratio of the substance quantity of oxidizing agent is 1:1: 3:0.01:0.15. The reaction bottle was pumped and ventilated three times to ensure that the reaction tube was anhydrous and oxygen-free, then sealed, and the reaction was placed under 455nm blue light (Blue LED light) and stirred for 2 hours. The distance between the Blue LED light and the Schlenk tube was 3cm. After the TLC detection reaction was completed, the reaction solution was transferred to an eggplant-shaped bottle, an appropriate amount of silica gel was added to concentrate under reduced pressure, and the resulting residue was purified by column chromatography (PE / EA=100:1), as Figure 3-4 As shown, the synthesized produ...

Embodiment 3

[0071] In a dry 10mL Schlenk tube, add 90.4mg N-phenylglycine, 24.7mg p-methoxyaniline, 2.6mg photocatalyst {Ir[dF(CF 3 )ppy] 2 bpy}PF6 , 12.1mg oxidant Co(dmgH 2 ) 2 PyCl, 2mL1,2-dichloroethane, 24.9mg o-fluorobenzaldehyde, o-fluorobenzaldehyde: p-methoxyaniline: N-phenylglycine: photocatalyst: oxidizing agent The amount of substance is 1:1:3: 0.01:0.15. The reaction bottle was pumped and ventilated three times to ensure that the reaction tube was anhydrous and oxygen-free, then sealed, and the reaction was placed under 455nm blue light (Blue LED light) and stirred for 2 hours. The distance between the Blue LED light and the Schlenk tube was 3cm. After the TLC detection reaction was completed, the reaction solution was transferred to an eggplant-shaped bottle, an appropriate amount of silica gel was added to concentrate under reduced pressure, and the resulting residue was purified by column chromatography (PE / EA=100:1), as Figure 5-6 As shown, the synthesized product is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com