Light reusable thermal insulation material and preparation method thereof

A technology of thermal insulation materials and composite materials, which is applied in the field of lightweight and reusable thermal insulation materials and their preparation, can solve the problems of low bearing capacity, inability to further prevent heat flow transfer, and large thermal conductivity, so as to adapt to the external environment. Strong ability of heating change, excellent ablation and heat insulation function, strong shape and heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

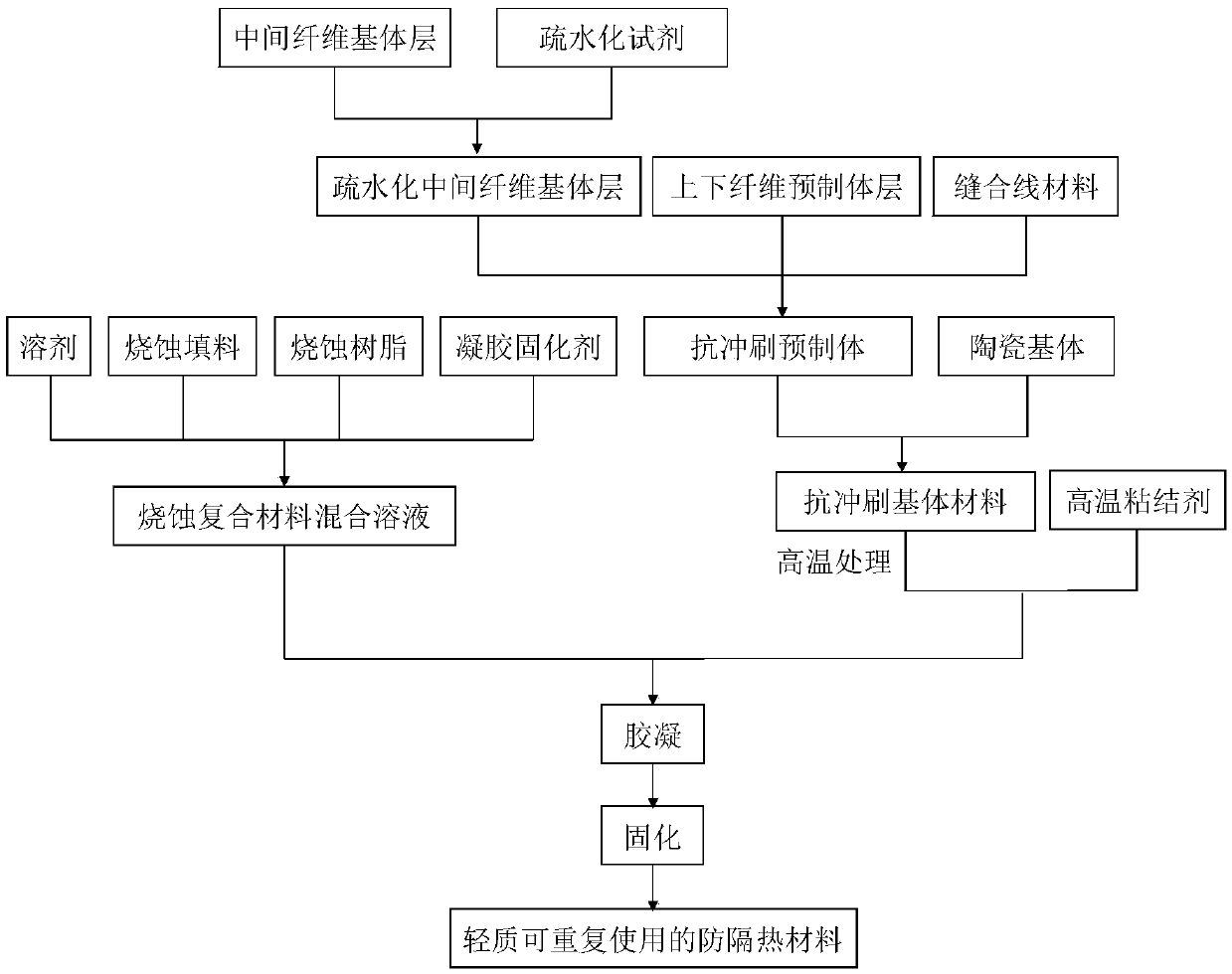

[0040] In a second aspect, the present invention provides a method for preparing the heat-resistant insulation material described in the first aspect of the present invention, the method comprising the following steps:

[0041] (1) Combining the upper fiber prefabricated body layer, the middle fiber matrix layer and the lower fiber prefabricated body layer (for example, by bonding, sewing or winding) to obtain an anti-scouring prefabricated body;

[0042] (2) Composite the anti-scouring prefabricated body obtained in step (1) with a ceramic matrix to obtain an anti-scouring matrix material; The prefabricated body is impregnated and compounded, so as to realize the densification of the upper and lower fiber prefabricated body layers, and obtain the anti-scour matrix material; In the scour matrix material, the mass ratio of the ceramic matrix to the scour-resistant preform can also be effectively adjusted according to the number of immersions;

[0043] (3) impregnating (for exa...

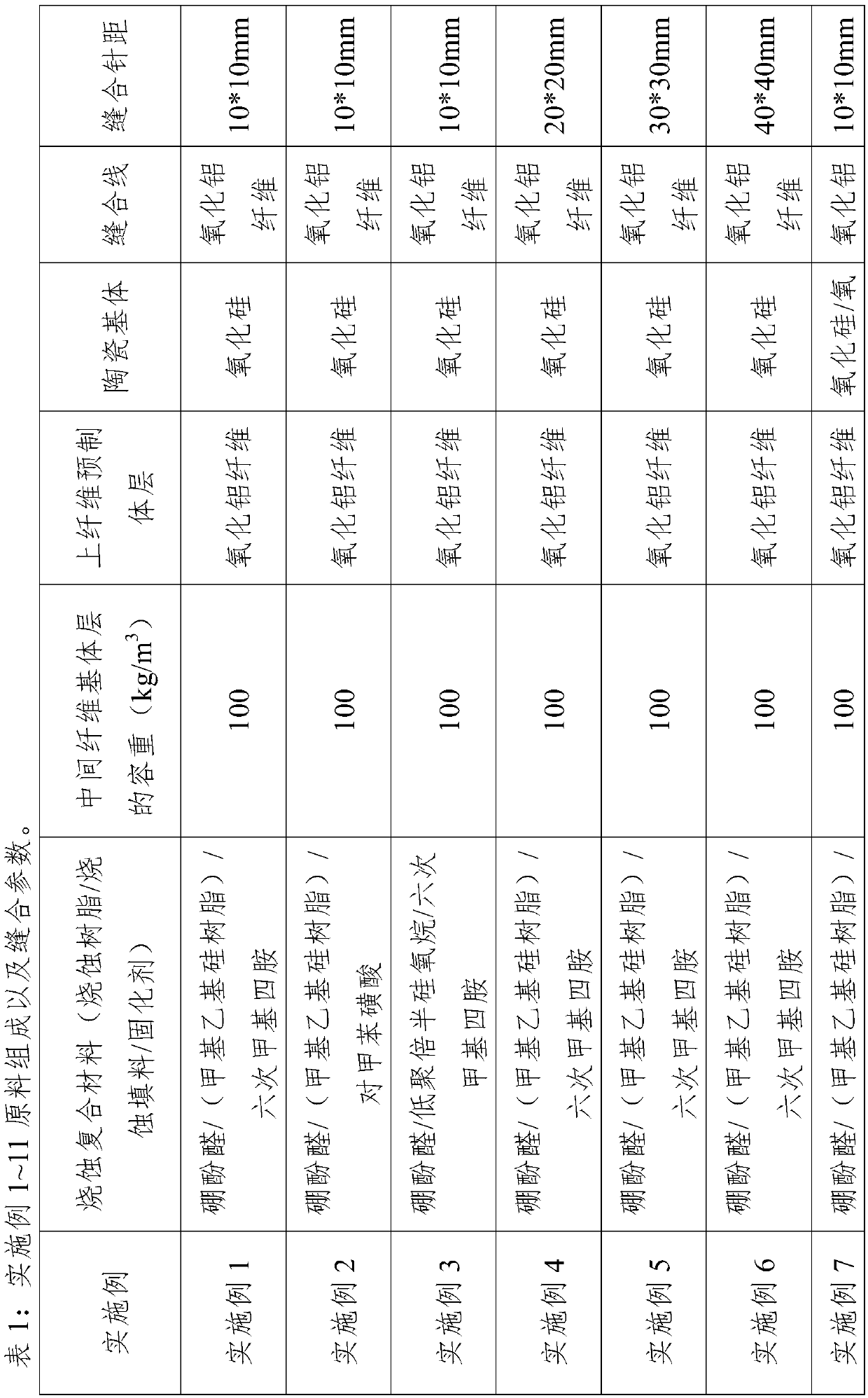

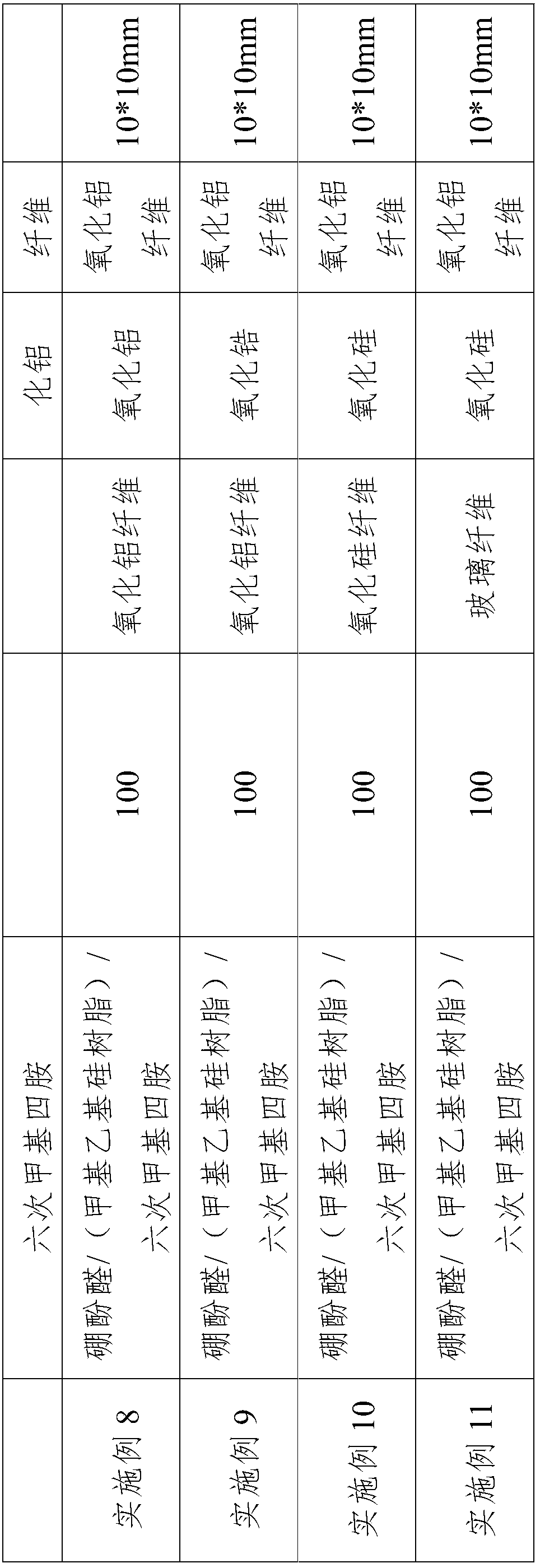

Embodiment 1

[0052] ① Preparation of anti-scouring prefabricated body: mullite fiber is selected as the intermediate fiber matrix layer, and the bulk density is 100kg / m 3 , thickness 25mm, size 150×150mm, using methyltrimethoxysilane as hydrophobizing agent, using gas phase hydrophobic method to hydrophobize the intermediate fiber matrix layer; choose alumina fiber weaving 2.5D upper fiber preform layer, oxidation Aluminum fiber diameter 10μm, braiding thickness 2mm, volume fraction 40%, quartz fiber weaving 2.5D lower fiber prefabricated body layer, quartz fiber diameter 8mm, braiding thickness 0.5mm, volume fraction 40%; Layer / intermediate fiber matrix layer / 0.5mm lower fiber prefabricated body layer is superimposed for integrated suture. Alumina fiber is selected as the suture material. The diameter of a single alumina fiber is 8mm, the line density is 800tex, and the suture gauge It is 10*10mm, and the anti-scouring prefabricated body is obtained.

[0053] ②Preparation of the anti-sco...

Embodiment 12

[0060] Embodiment 12 is basically the same as Embodiment 1, the difference is:

[0061] In ②, the anti-scouring matrix material with a mass ratio of ceramic matrix and anti-scouring preform of 40:100 was obtained.

[0062] The same test method as in Example 1 was used to perform a performance test on the heat-resistant insulation material prepared in this example, and the performance test results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com