Preparation method of graded porous carbon

A technology of hierarchical porous and foaming agent, applied in carbon preparation/purification, etc., can solve the problems of accelerated desalination speed, low ion diffusion resistance, small specific surface area of mesoporous carbon, etc., and achieve the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 0.1g of potassium carbonate powder with a particle size of 1000 mesh to 10g of low-temperature coal tar pitch, grind it evenly, put it into the reaction kettle under nitrogen, the pressure in the kettle is 1.0Mpa, and heat it to 80℃ at a speed of 5℃ / min. Constant temperature magnetic stirring for 30min, then heating to 340°C at a speed of 5°C / min, reacting for 1h, then heating to 850°C at a speed of 20°C / min, reacting for 1h, cooling down to room temperature naturally, taking it out and putting in 1M Soak in hydrochloric acid for 6 hours, wash with water until nearly neutral, and dry to obtain a specific surface area of 500m 2 / g, the pore volume is 0.45cm 3 / g, the average pore diameter of micropores is 0.78nm, the average pore diameter of mesopores is 2.9nm, there are 70-100nm macropores, and the total average pore diameter is 2.1nm hierarchical porous carbon.

Embodiment 2

[0030] Add 10g of potassium carbonate powder with a particle size of 200 mesh to 10g of medium-temperature coal tar pitch, grind it evenly, put it into a reaction kettle under nitrogen, and heat it to 100℃ at a speed of 20℃ / min at a constant temperature of 5.0Mpa. Stir mechanically for 24 hours, then heat up to 340°C at a rate of 10°C / min, react for 1 hour, then heat up to 900°C at a rate of 30°C / min, react for 2 hours, cool down to room temperature naturally, take it out and put in 1M hydrochloric acid Soak in neutral water for 6 hours, wash with water until nearly neutral, and dry to obtain a specific surface area of 1200m 2 / g, the pore volume is 0.75cm 3 / g, the average pore diameter of micropores is 0.9nm, the average pore diameter of mesopores is 3.8nm, there are 80-120nm macropores, and the total average pore diameter is 2.9nm.

Embodiment 3

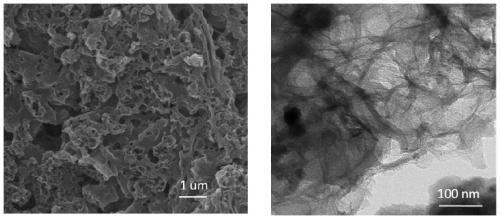

[0032] Add 100g of potassium citrate powder with a particle size of 100 mesh to 10g of high-temperature coal tar pitch, grind it evenly, put it into a reaction kettle under argon, and heat it to 150℃ at a speed of 0.1℃ / min at a pressure of 0.1Mpa. , ultrasonic at constant temperature for 5 hours, then heated to 250°C at a speed of 50°C / min, reacted for 1h, then heated to 700°C at a speed of 5°C / min, reacted for 1h, cooled down to room temperature naturally, took it out and put in 1M Soak in hydrochloric acid for 8 hours, wash with water until nearly neutral, and dry to obtain a specific surface area of 1500m 2 / g, the pore volume is 1.50cm 3 / g, the micropore average aperture is 0.78nm, the mesopore average aperture is 6.7nm, there are 300-1100nm macropores, and the total average aperture is the hierarchical porous carbon of 4.5nm (such as figure 1 shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com