Quantum dot laser and preparation method thereof

A technology of lasers and quantum dots, applied in the field of lasers, can solve problems such as laser defects, and achieve the effects of easy operation and implementation, elimination of dislocation defects, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

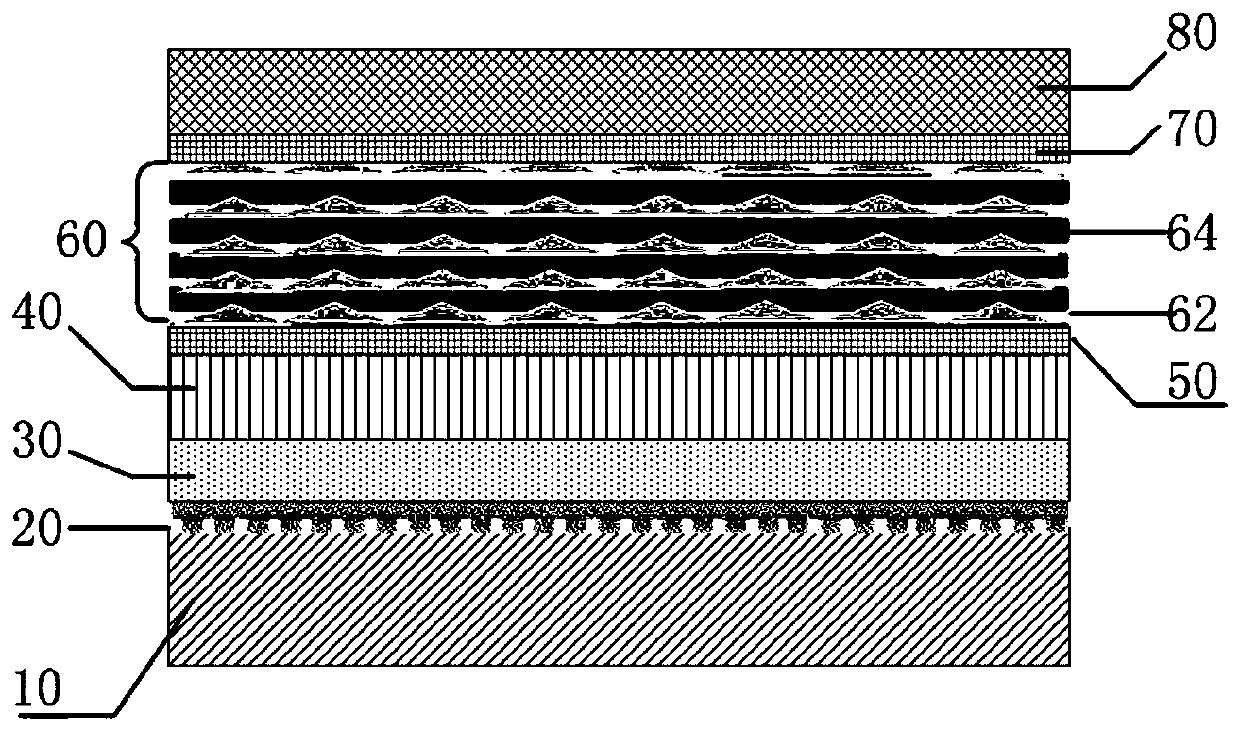

[0085] An embodiment of the present invention provides a method for preparing a quantum dot laser, comprising the following steps:

[0086] S1. Select a single crystal silicon substrate;

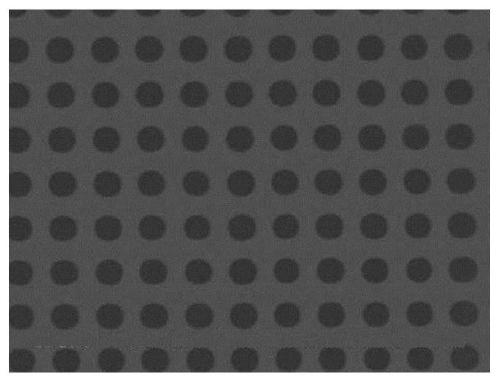

[0087] S2. Etching several holes on the single crystal silicon substrate to obtain a porous single crystal silicon substrate;

[0088] S3. Growing a filling layer, a lower electrode, a first superlattice waveguide layer, an active region, a second superlattice waveguide layer, and an upper electrode sequentially on a porous single crystal silicon substrate to obtain a quantum dot laser.

[0089] The present invention obtains a porous single crystal silicon substrate by etching several holes on the single crystal silicon substrate, and the obtained porous single crystal silicon substrate can eliminate a large number of dislocation defects caused by the lattice mismatch between it and the material in the active region , which has the advantages of simple method and convenient operation and im...

Embodiment

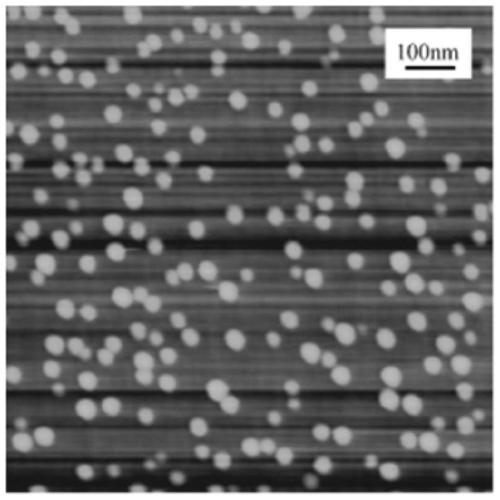

[0104] (1) On a single crystal silicon substrate with a thickness of about 380 μm, a circle with a diameter of 50 nm and a depth of 100 nm is fabricated on the single crystal silicon substrate by photolithography technology, and the SF 6 Reactive etching gas, the etching power is 200W, the reaction gas pressure is 25Pa, the reaction gas flow rate is 35sccm, and the etching time is 10 seconds to obtain a porous single crystal silicon substrate;

[0105] (2) In the epitaxial growth chamber, first heat the porous single crystal silicon substrate to 940°C for 600s, then lower the temperature of the porous single crystal silicon substrate to 580°C, grow a 150nm GaAs filling layer, pause for 30s, and then grow again 500nm GaAs buffer layer;

[0106] (3) Grow n-type doped Al on the GaAs buffer layer 0.3 Ga 0.7 As bottom electrode, the thickness is 1.5 microns, the growth temperature is 580°C, the growth rate is 0.598 μm / h, the doping element is Be, and the doping concentration is ×...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com