Quantum wire laser and preparation method thereof

A laser and quantum wire technology, applied in the field of lasers, can solve the problem of inability to achieve simultaneous lasing of multiple wavelengths, and achieve the effect of easy operation and implementation, and the method is simple and easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

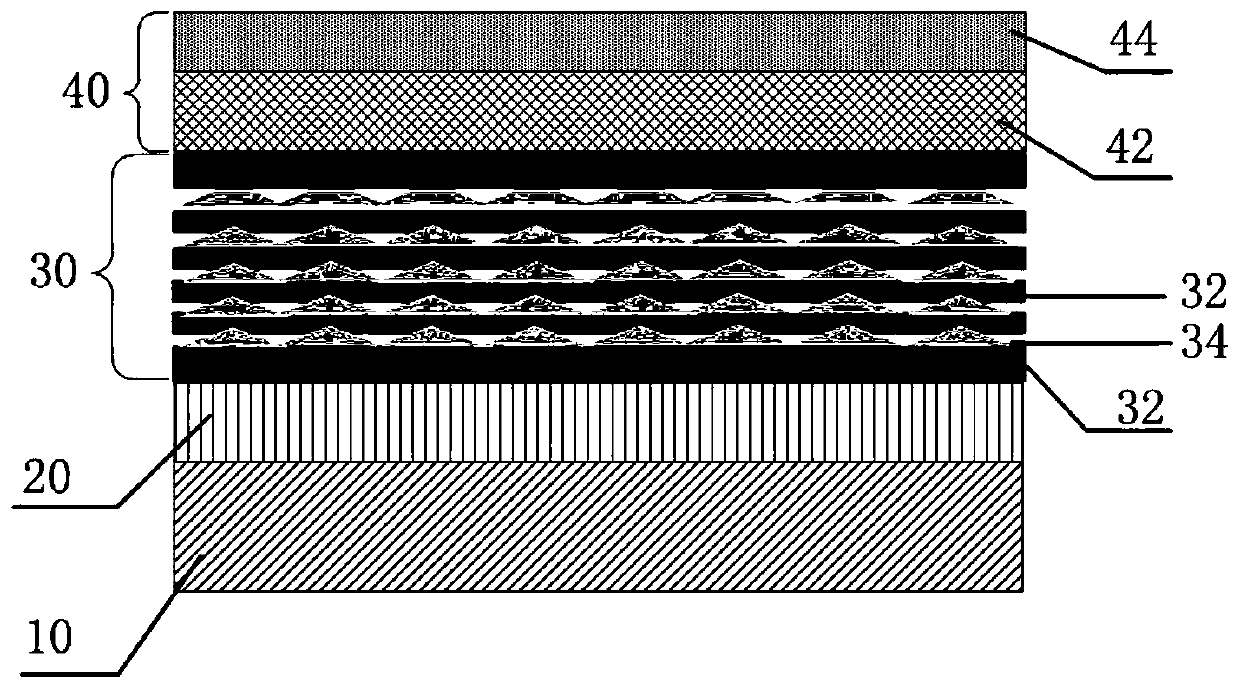

[0068] An embodiment of the present invention provides a method for preparing a quantum wire laser, including the following steps:

[0069] S1. Select a substrate;

[0070] S2, sequentially growing a buffer layer, an active region, and a top electrode on the substrate;

[0071] After etching, a quantum wire laser is obtained;

[0072] Wherein, the active region is obtained by taking the spacer layer as the bottom layer and the top layer by alternately growing the spacer layer and the indium arsenide quantum wire layer.

[0073] In the present invention, a buffer layer, an active region and a top electrode are sequentially grown on a substrate by gas source molecular beam epitaxy (GSMBE), and at least one indium arsenide quantum wire layer is arranged in the active region, and the method is simple and convenient. Advantages of operational implementation.

Embodiment

[0093] (1) By gas source molecular beam epitaxy (GSMBE), a 600nm thick n-InGaAsP buffer layer is first grown on an N-type InP substrate, the doping element is Si, and the doping concentration is 3×10 18 / cm 3 , the growth temperature is 530°C;

[0094] (2) On the n-InGaAsP buffer layer, continue to grow a non-doped InGaAsP lower surface optical waveguide dielectric layer with a thickness of 200nm, the growth temperature is 530°C, and the optical waveguide band gap is 1.05ev (equivalent to a wavelength of 1.18μm);

[0095] (3) The quantum wires in the active region are composed of 5 layers of InAs. The growth temperature of each layer of InAs quantum wires is 485°C, the growth rate is 0.1ML / s, the growth thickness is 3.5ML, and the growth time is 35s. AsH 3 The air pressure in the chamber is 630Torr, and the air pressure in the growth chamber is 1.5×10 -5 Torr;

[0096] (4) In order to prevent the interference between each layer of quantum wires, each layer of InAs quantum w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com