Method for analyzing and predicting formability of MAX-phase material

A 413-MAX and 312-MAX technology, applied in visual data mining, special data processing applications, structured data retrieval, etc., can solve problems such as time-consuming, low prediction accuracy, and expensive testing costs, and achieve cost savings, The effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below with reference to the accompanying drawings, which is an explanation rather than a limitation of the present invention.

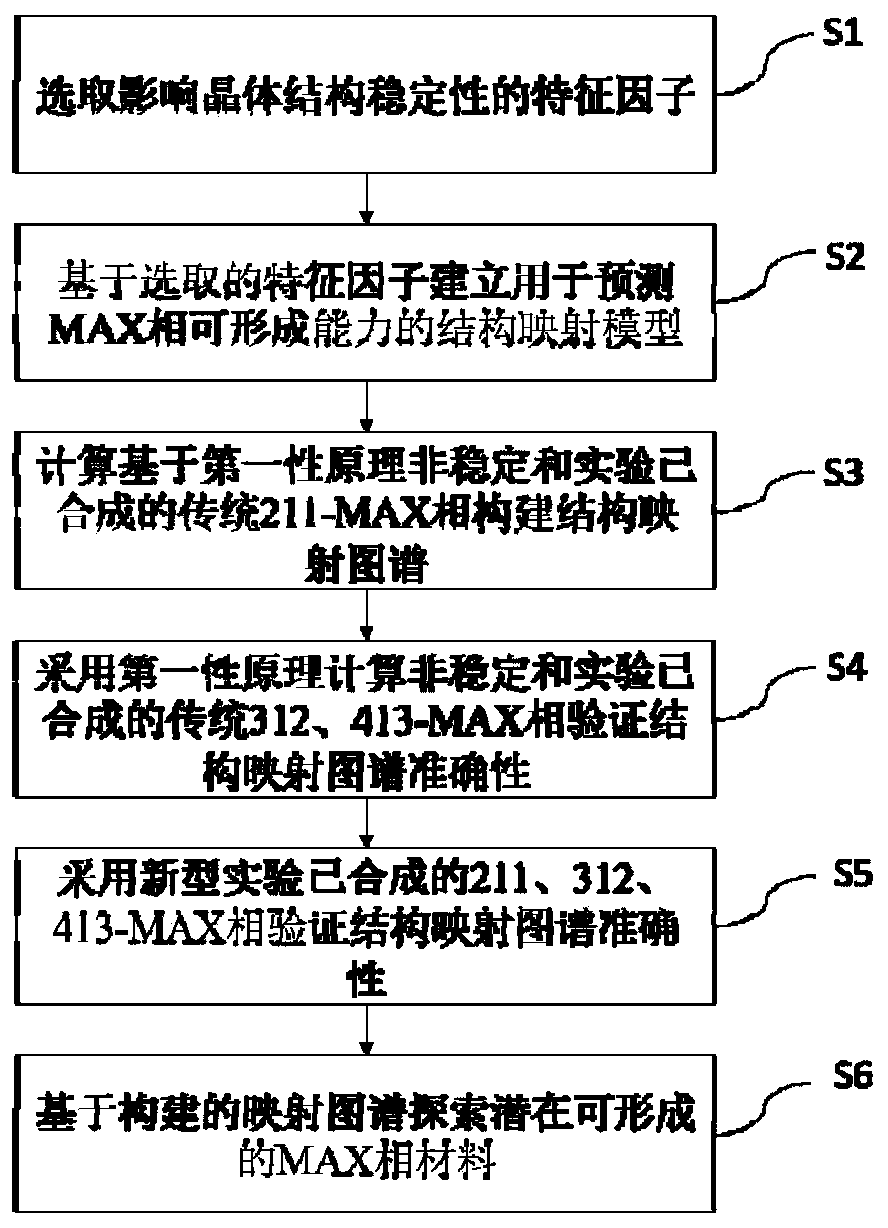

[0032] Refer to figure 1 , A method for analyzing and predicting the forming ability of MAX phase materials, including the following steps:

[0033] Step S1: Select characteristic factors that affect the stability of the material structure;

[0034] Specifically, in this step S1, the following characteristic factors are selected based on Hume-Rothery and Barsoum's exploration of the alloy law and MAX phase electronic structure, as shown in the following table:

[0035]

[0036] Step S2: Establish a structure mapping model for predicting the formation ability of MAX phase based on the selected feature factors.

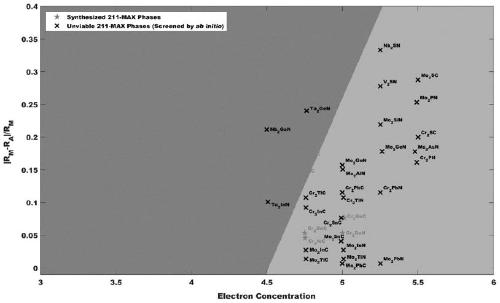

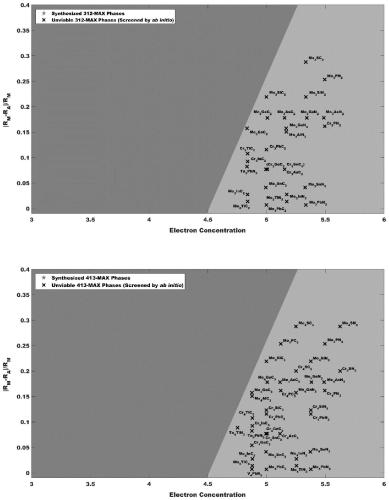

[0037] Specifically, in this step S2, two characteristic equations are further established by selecting the electron concentration factor and the size factor, respectively:

[0038]

[0039]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com