Medium-carbon wheel steel suitable for freight trains in alpine regions and method for producing wheels by using medium-carbon wheel steel

A technology for high and cold regions and production methods, applied in the field of alloy manufacturing, can solve the problems of low temperature toughness and wear resistance, wheel wear resistance, low temperature performance and other problems, so as to improve the precipitation strengthening effect and mechanical properties. The effect of high level and reduced particle spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- Embodiment 3

[0034] A medium-carbon wheel steel suitable for trucks in alpine regions. The chemical composition mass fraction of the wheel steel is shown in Table 1, and the balance not listed in Table 1 is Fe and unavoidable impurity elements.

Embodiment 1

[0036] The medium-carbon wheel steel production wheel suitable for trucks in alpine regions described in Embodiment 1:

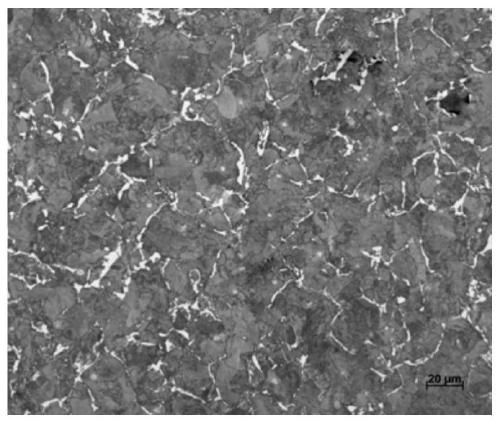

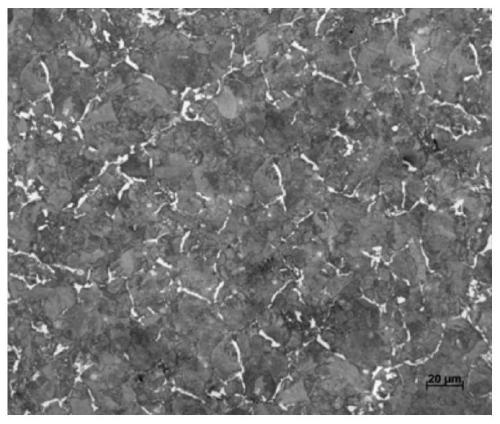

[0037] The molten steel whose chemical composition is shown in Example 1 in Table 1 is formed through electric furnace steelmaking process, LF furnace refining process, RH vacuum treatment process, round billet continuous casting process, ingot cutting hot rolling process, heat treatment process, processing, and finished product inspection process. The heat treatment process is as follows: first, heat the wheel with the furnace to 870°C and keep it warm for 2.7 hours, then spray water on the rim to cool it below 500°C (the metal on the surface layer of the rim is cooled slowly at 2°C / s-5°C / s to produce pearlite At the same time, the carbonitride of the microalloying element V will undergo solid solution and precipitation during the heat preservation and cooling process), then, the wheel is air-cooled to room temperature; , due to the existence of solid solut...

Embodiment 2

[0041] The medium-carbon wheel steel production wheel suitable for trucks in alpine regions described in embodiment 2:

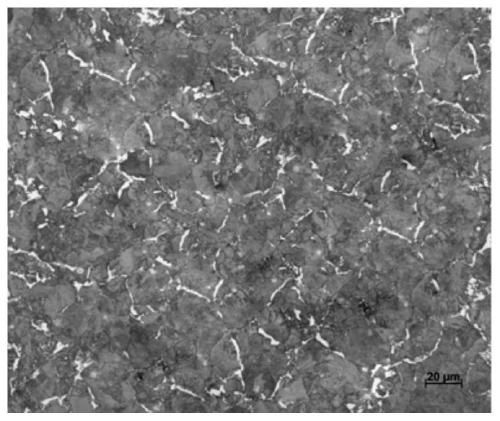

[0042] The molten steel whose chemical composition is shown in Example 2 of Table 1 is formed through electric furnace steelmaking process, LF furnace refining process, RH vacuum treatment process, round billet continuous casting process, ingot cutting hot rolling process, heat treatment process, processing, and finished product inspection process. The heat treatment process is as follows: first, heat the wheel with the furnace to 860°C and keep it warm for 2.6 hours, then spray water on the rim to cool it below 500°C (the metal on the surface layer of the rim is cooled slowly at 2°C / s-5°C / s to produce pearlite At the same time, the carbonitrides of the microalloying element V will undergo solid solution and precipitation during the heat preservation and cooling process), then the wheel is air-cooled to room temperature, and the wheel is heated to 860°C with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com