Conductive nerve repair material with micro-nano topological structure and preparation method and application thereof

A topology and nerve repair technology, applied in pharmaceutical formulations, prostheses, drug delivery, etc., to achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

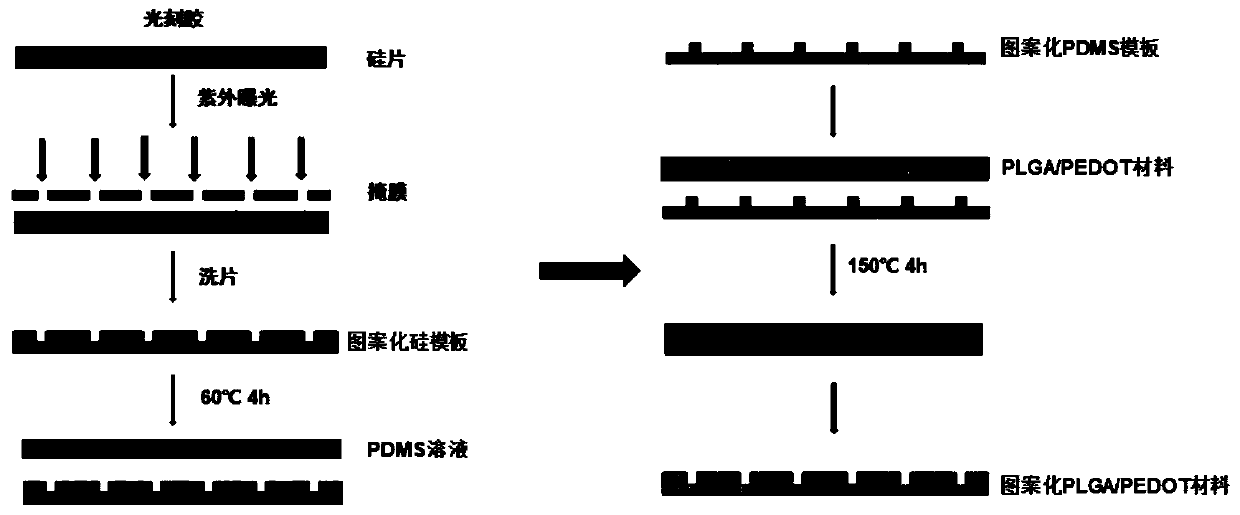

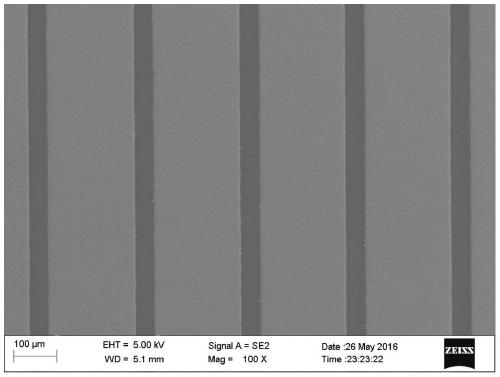

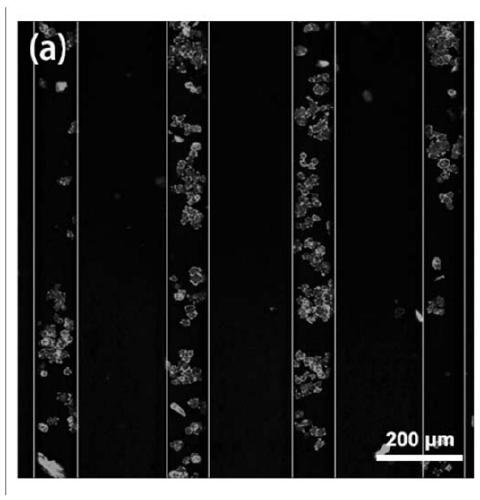

[0038] (1) Use CAD software to draw the top view of the micro-nano topological structure pattern, the groove spacing is 200 μm, the groove width is 25 μm, and a mask is made, and the micro-nano groove is prepared on the silicon wafer by photolithography technology using the mask Groove structure, and then cast PDMS prepolymer on the silicon wafer, after cross-linking and curing, a PMDS stamp with micro-nano groove structure is obtained.

[0039] (2) Weigh 20g of PLGA in 50ml of dichloromethane, stir the solution with a magnetic stirrer at a stirring rate of 150 r / min, and stir for 48 hours to form a uniform PLGA solution.

[0040] (3) Add 1.0g of PEDOT to a 50ml centrifuge tube, add 30ml of absolute ethanol to ultrasonically disperse evenly, then add the dispersion to the PLGA solution in step (2), continue to stir for 3 days, and carry out ultrasonic oscillation, stirring speed 150 r / min, stirring for 48h to form a PLGA / PEDOT composite solution.

[0041] (4) In the fume hood...

Embodiment 2

[0045] (1) Use CAD software to draw the top view of the 3D micro-groove pattern, the groove pitch is 200 μm, the groove width is 50 μm, and a mask is made, and the mask is used to prepare 3D micro-grooves on the silicon wafer by photolithography pattern, and then cast PDMS prepolymer on the silicon wafer, and obtain a PMDS substrate with a 3D micro-groove pattern after cross-linking and curing.

[0046] (2) Weigh 20g of PLGA in 50ml of dichloromethane, stir the solution with a magnetic stirrer at a stirring rate of 150 r / min, and stir for 48 hours to form a uniform PLGA solution.

[0047] (3) Add 1.0g of PEDOT to a 50ml centrifuge tube, add 30ml of absolute ethanol to ultrasonically disperse evenly, then add the dispersion to the PLGA solution in step (2), and continue to stir for 3 days at a stirring rate of 150 r / min , stirred for 48h to form a PLGA / PEDOT composite solution.

[0048] (4) In the fume hood, the solvent in the composite solution obtained in step (3) was volatili...

Embodiment 3

[0052] (1) Use CAD software to draw the top view of the 3D micro-groove pattern, the groove pitch is 200 μm, the groove width is 100 μm, and a mask is made, and the mask is used to prepare 3D micro-grooves on the silicon wafer by photolithography pattern, and then cast PDMS prepolymer on the silicon wafer, and obtain a PMDS substrate with a 3D micro-groove pattern after cross-linking and curing.

[0053] (2) Weigh 20g of PLGA in 50ml of dichloromethane, stir the solution with a magnetic stirrer at a stirring rate of 150 r / min, and stir for 48 hours to form a uniform PLGA solution.

[0054] (3) Add 1.0g of PEDOT to a 50ml centrifuge tube, add 30ml of absolute ethanol to ultrasonically disperse evenly, then add the dispersion to the PLGA solution in step (2), and continue to stir for 3 days at a stirring rate of 150 r / min , stirred for 48h to form a PLGA / PEDOT composite solution.

[0055] (4) In the fume hood, the solvent in the composite solution obtained in step (3) was volat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com