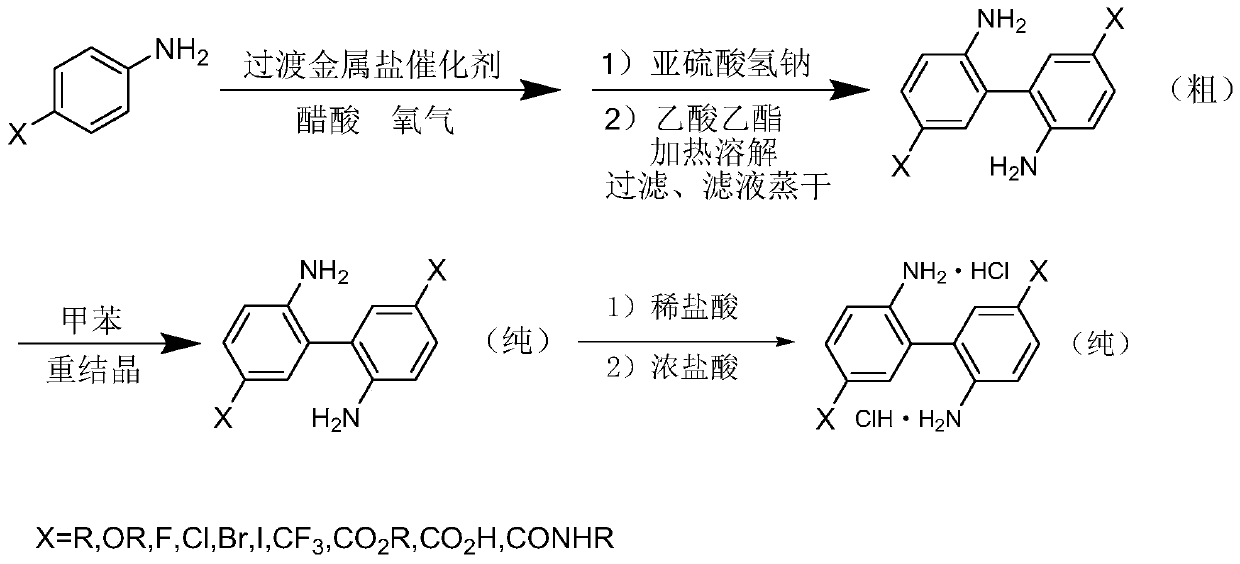

Method for preparing 4,4'-disubstituted-2,2'-diaminodiphenyl and hydrochloride thereof by continuous flow oxidative coupling method

A technology of diaminobiphenyl hydrochloride and diaminobiphenyl, which is applied in the field of downhole operations in oil and gas fields, can solve the problems of many reaction steps, unfavorable mass production, high cost, etc., and achieves mild reaction conditions, few synthetic precursors, and controlled production. Warm and precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

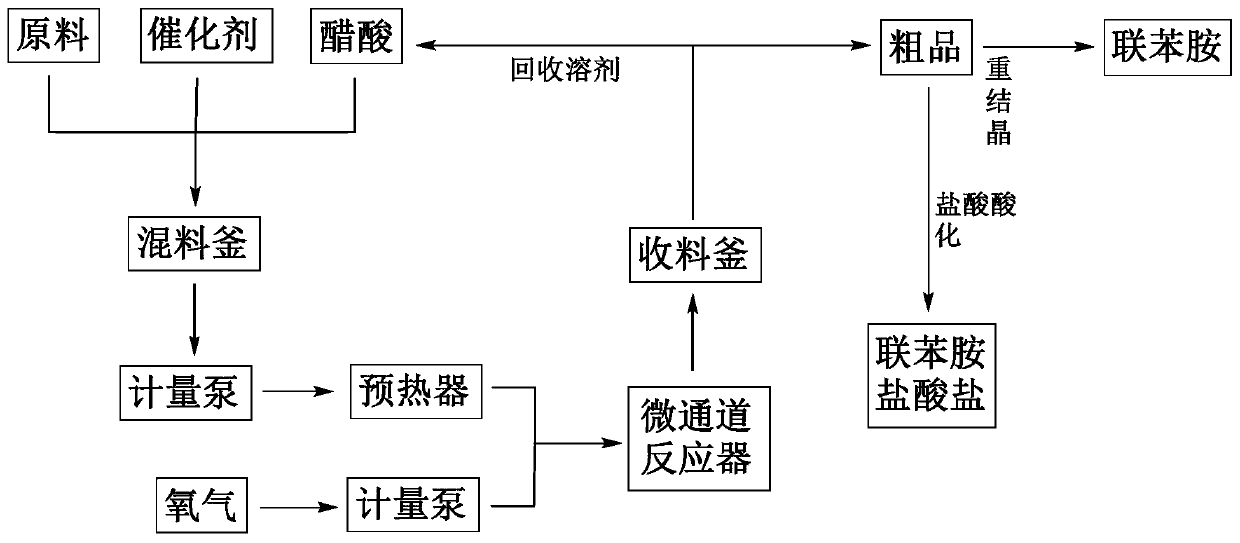

Method used

Image

Examples

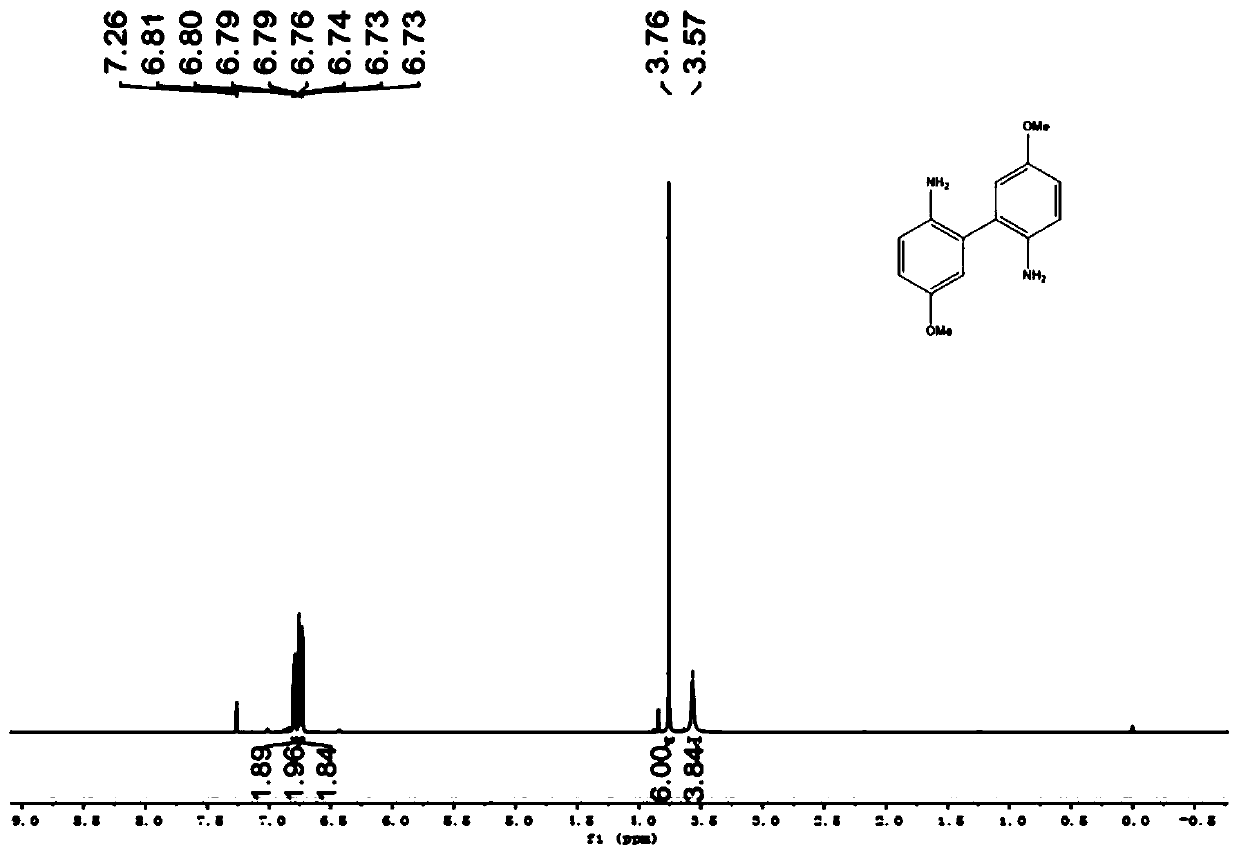

Embodiment 1

[0032] S1, dissolving 0.1g of copper chloride in 400g of glacial acetic acid to form a glacial acetic acid solution of copper chloride, and then dissolving 200g of p-methoxyaniline in the glacial acetic acid solution of copper chloride to form a reaction solution;

[0033] S2. After the reaction solution prepared in step S1 is preheated to 50°C in the preheating module of the microchannel reactor, it enters the reaction module at a liquid flow rate of 100 mL / min through a metering pump; Pure oxygen is passed into the reaction module of the microchannel reactor through a metering pump at a gas flow rate of 2400mL / min, so that p-methoxyaniline and pure oxygen are mixed in the reaction module according to the molar ratio of 1:4, and the gas flow rate is 1.2MPa. React for 45s, then the oxidative coupling product generated by the reaction is transferred to the receiving tank after cooling;

[0034] S3. Add 6g of sodium bisulfite to the receiving kettle and stir the reaction for 1h to...

Embodiment 2

[0037] S1, ferrous chloride 1g is dissolved in 350g glacial acetic acid, forms the glacial acetic acid solution of ferrous chloride, then 200g p-methoxyaniline is dissolved in the glacial acetic acid solution of ferrous chloride, forms reaction solution;

[0038] S2. After the reaction solution prepared in step S1 is preheated to 80° C. in the preheating module of the microchannel reactor, it enters the reaction module at a liquid flow rate of 200 mL / min through a metering pump; Pure oxygen is passed into the reaction module of the microchannel reactor through a metering pump at a gas flow rate of 5600mL / min, so that p-methoxyaniline and pure oxygen are mixed in the reaction module according to the molar ratio of 1:5, and the gas is mixed under the condition of 1.5MPa Reaction 75s, then the oxidative coupling product that reaction generates is transferred in the receiving kettle after cooling;

[0039] S3. Add 10g of sodium bisulfite to the receiving kettle and stir for 1h to ...

Embodiment 3

[0042] S1, ferrous ammonium sulfate 2g is dissolved in 380g glacial acetic acid, forms the glacial acetic acid solution of ferrous ammonium sulfate, then 200g p-methoxyaniline is dissolved in the glacial acetic acid solution of ferrous ammonium sulfate, forms reaction solution;

[0043] S2. After the reaction solution prepared in step S1 is preheated to 75°C in the preheating module of the microchannel reactor, it enters the reaction module at a liquid flow rate of 100 mL / min through a metering pump; Pure oxygen is passed into the reaction module of the microchannel reactor through a metering pump at a gas flow rate of 2000mL / min, and pure oxygen is passed into the reaction module of the microchannel reactor at the same time, so that p-methoxyaniline and pure oxygen are in a molar ratio of 1 : 5 mixed in the reaction module, and reacted for 50s under the condition of 2MPa, then the oxidative coupling product generated by the reaction was cooled and then transferred to the recei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com