Road inspection well and manufacturing process and construction method thereof

A technology of manufacturing process and inspection well, which is applied in the field of road inspection well and its manufacturing process and construction, can solve the problems of poor crack resistance and short service life, achieve improved crack resistance, improve corrosion resistance, reduce micro The effect of crack chance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

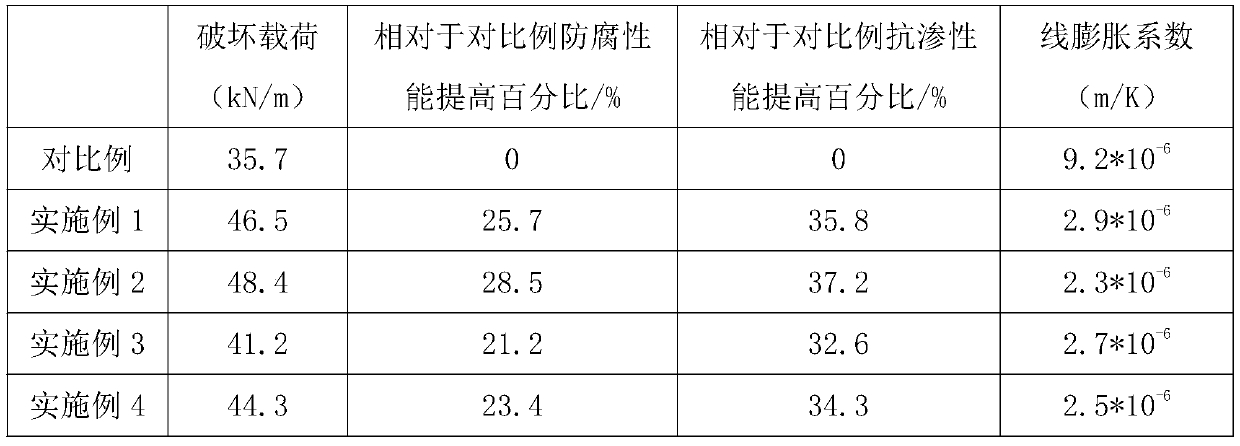

Examples

Embodiment 1

[0042] A road inspection well, which is composed of the following raw materials in weight ratio: 320 parts of Portland cement, 565 parts of medium sand, 550 parts of superabsorbent resin, 820 parts of stone, 65 parts of fiber mixture, 80 parts of fly ash, expansion 35 parts of water reducing agent, 20 parts of polycarboxylate superplasticizer, 60 parts of gravel-type ceramsite, 45 parts of montmorillonite powder, 35 parts of attapulgite, 25 parts of retarder, 20 parts of early strength agent and 885 parts of water;

[0043] A manufacturing process for a road inspection well, comprising the following steps:

[0044] a. Place the fiber mixture, fly ash, crushed stone-type ceramsite, montmorillonite powder and attapulgite in a pulverizer to pulverize, then sieve, and store the fine powder of each raw material for future use;

[0045] b. Put Portland cement, medium sand and gravel together in the mixer, and mechanically stir at a rate of 300r / min. After stirring for 20min, add the...

Embodiment 2

[0064] A road inspection well, which is composed of the following raw materials in the following weight ratio: 300 parts of Portland cement, 580 parts of medium sand, 500 parts of super absorbent resin, 850 parts of stone, 70 parts of fiber mixture, 90 parts of fly ash, expansion 30 parts of water-reducing agent, 25 parts of polycarboxylate superplasticizer, 55 parts of gravel-type ceramsite, 50 parts of montmorillonite powder, 30 parts of attapulgite, 30 parts of retarder, 15 parts of early strength agent and 950 parts of water;

[0065] A manufacturing process for a road inspection well, comprising the following steps:

[0066] a. Place the fiber mixture, fly ash, crushed stone-type ceramsite, montmorillonite powder and attapulgite in a pulverizer to pulverize, then sieve, and store the fine powder of each raw material for future use;

[0067] b. Put Portland cement, medium sand and gravel together in the mixer, and mechanically stir at a rate of 420r / min. After stirring for...

Embodiment 3

[0086] A road inspection well, which is composed of the following raw materials in the following weight ratio: 355 parts of Portland cement, 600 parts of medium sand, 700 parts of superabsorbent resin, 860 parts of stone, 75 parts of fiber mixture, 95 parts of fly ash, expansion 50 parts of water reducing agent, 30 parts of polycarboxylate superplasticizer, 70 parts of gravel-type ceramsite, 60 parts of montmorillonite powder, 45 parts of attapulgite, 35 parts of retarder, 28 parts of early strength agent and 1000 parts of water;

[0087] A manufacturing process for a road inspection well, comprising the following steps:

[0088] a. Place the fiber mixture, fly ash, crushed stone-type ceramsite, montmorillonite powder and attapulgite in a pulverizer to pulverize, then sieve, and store the fine powder of each raw material for future use;

[0089] b. Put Portland cement, medium sand and stones together in the mixer, and mechanically stir at a rate of 480r / min. After stirring for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com