CO-containing raw gas conversion and heat recovery method

A raw material gas and shift reaction technology, applied in steam generation methods, chemical instruments and methods, climate sustainability, etc., can solve problems affecting the long-term stable operation of the transform unit, difficulty in raising the temperature of the raw gas, and small temperature differences in the raw gas, etc. problems, to achieve the effect of improving waste heat recovery efficiency, saving equipment investment and land occupation, and reducing system resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

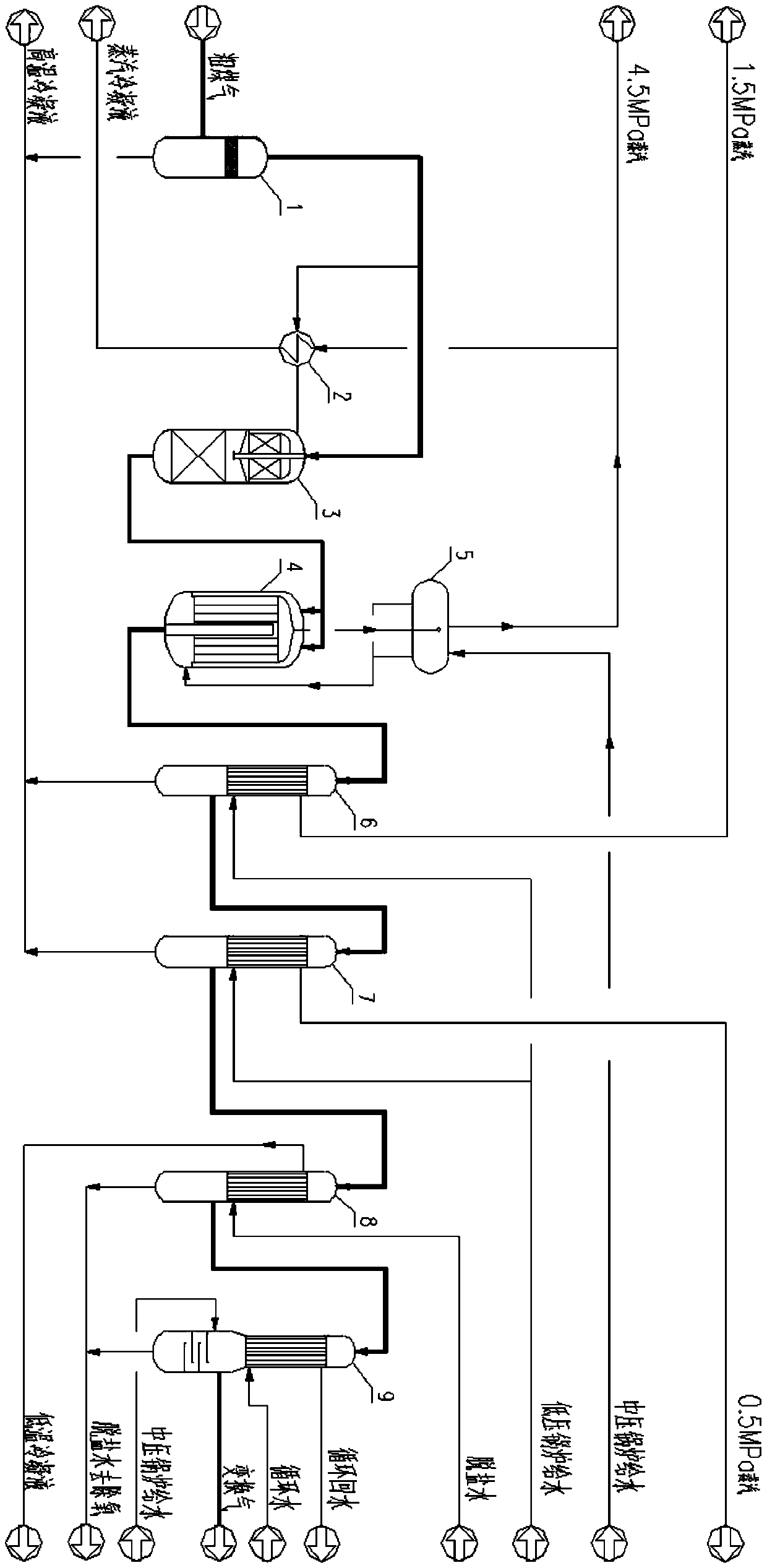

[0041] Such as figure 2 As shown, the crude gas from the coal-water slurry gasification device (pressure is 6.3MPaG, temperature 240 ℃), after the liquid water is separated by the raw material gas separator 1, it is divided into two shares, and one of which is about 25% of the crude gas through the raw gas The preheater 2 is heated to 260°C and enters the upper section of the self-heating purification furnace 3. After the reaction, it is fully mixed with another about 75% of the crude gas that directly enters the center tube, and the temperature is about 275°C. , and then enter the temperature-controlled shift furnace 4 to carry out the shift reaction. The raw gas entering the temperature-controlled shift furnace, under the action of the inter-tube shift catalyst, CO and H 2 The shift reaction of O occurs, and the shift reaction releases a large amount of reaction heat. After heat exchange with the boiler feed water in the tube, 4.5MPa steam is produced by-product. The by-pr...

Embodiment 2

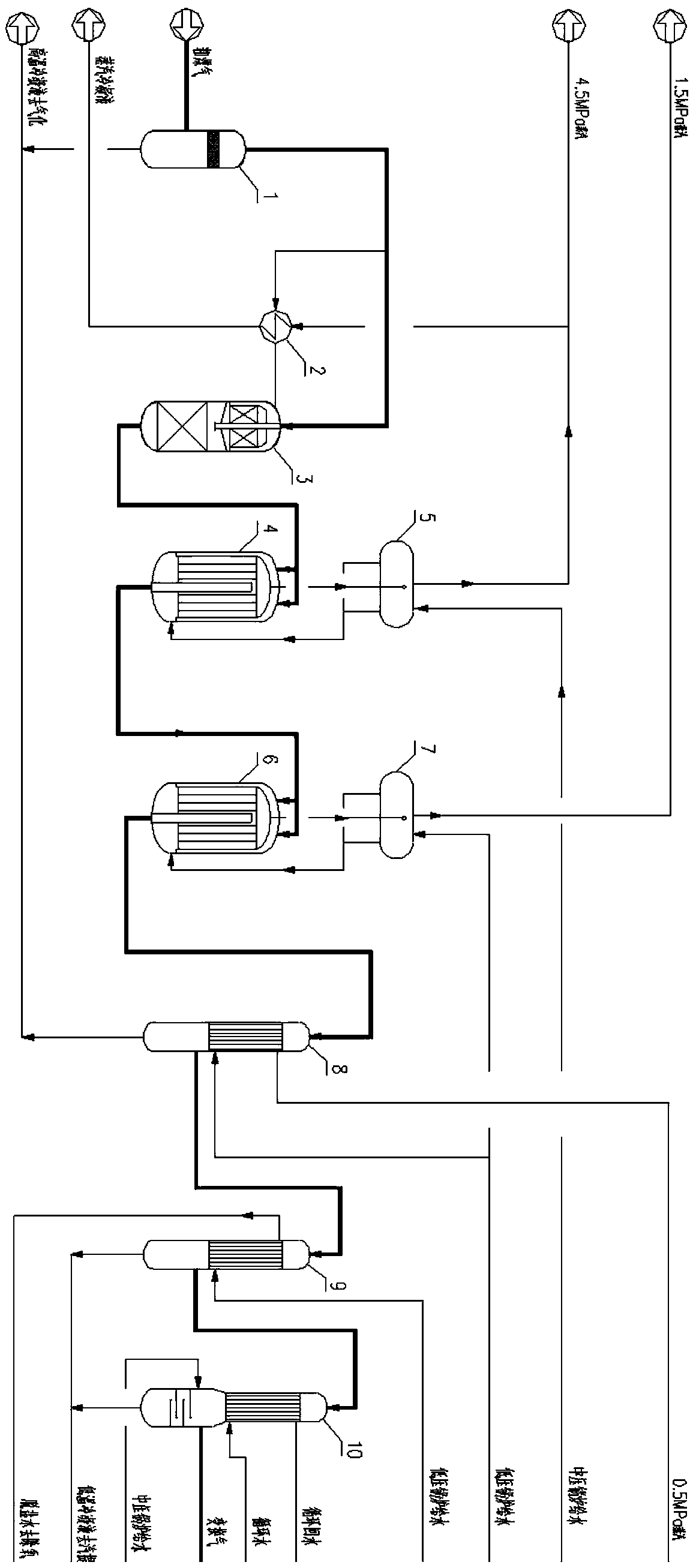

[0043] Such as image 3 As shown, the crude gas from the coal-water slurry gasification device (pressure is 6.0MPaG, temperature 232 ℃) is divided into two shares after separating the liquid water by the raw material gas separator 1, and one of them is about 12% of the crude gas. The heater 2 is heated to 260°C and enters the upper section of the self-heating purification furnace 3. After the reaction, it is mixed with another stream of about 88% crude gas through the central tube, and the temperature is about 265°C, and then the temperature is about 265°C, and the dust and poisons are removed in the lower section of the self-heating purification furnace 3. Then enter the first-stage temperature-controlled shift furnace 4 to carry out the shift reaction. The raw gas entering the temperature-controlled shift furnace, under the action of the inter-tube shift catalyst, CO and H 2 O occurs a shift reaction, and the shift reaction releases a large amount of reaction heat. After he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com