A method for recycling and regenerating positive electrode materials of lithium iron phosphate waste batteries

A technology for lithium iron phosphate and waste batteries, which is applied in the field of recycling and regeneration of lithium iron phosphate waste battery cathode materials, can solve the problems of secondary pollution of waste liquid and waste gas, strict control of process parameters, and numerous process steps, so as to protect the environment and avoid secondary pollution. Secondary pollution, simple and quick process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

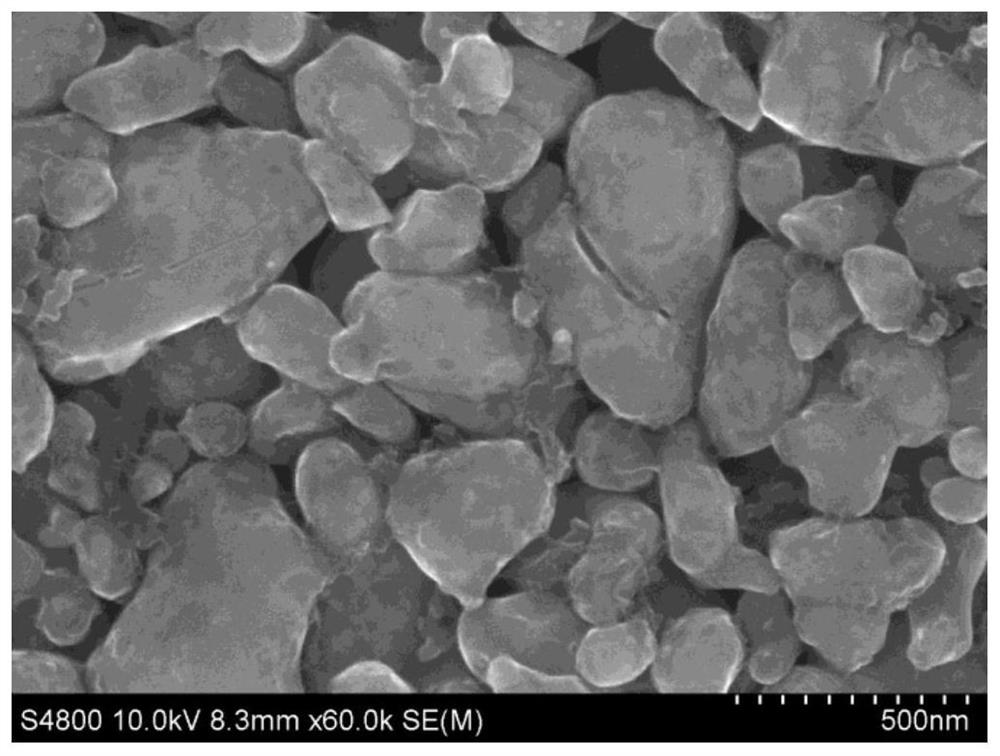

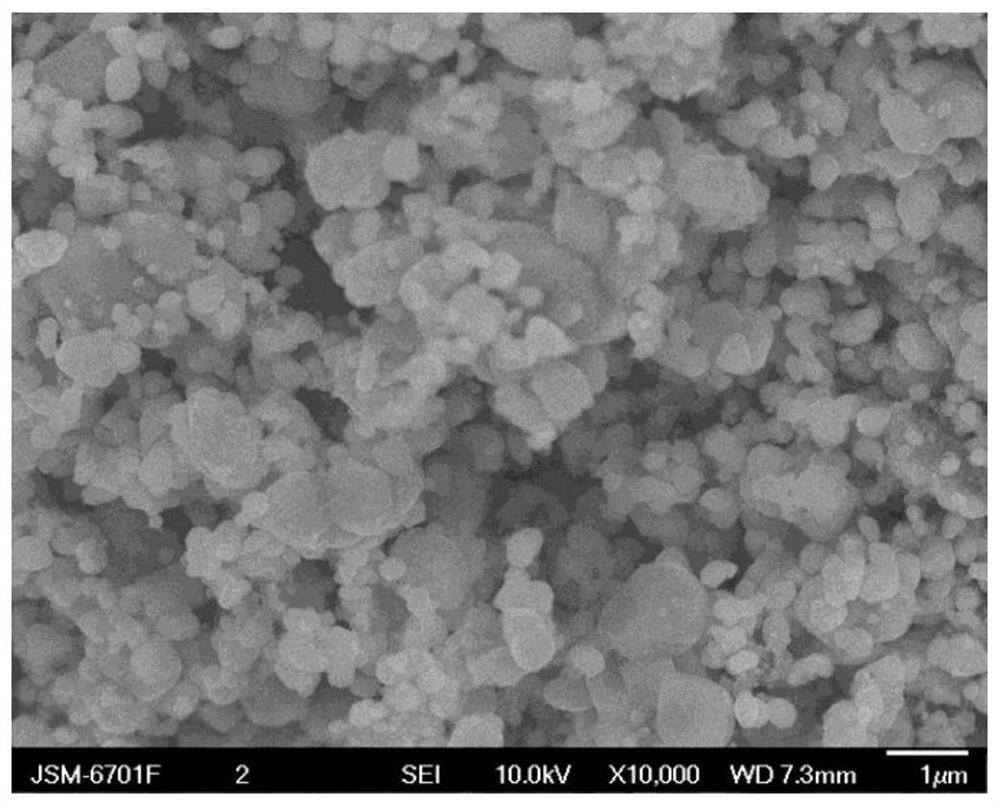

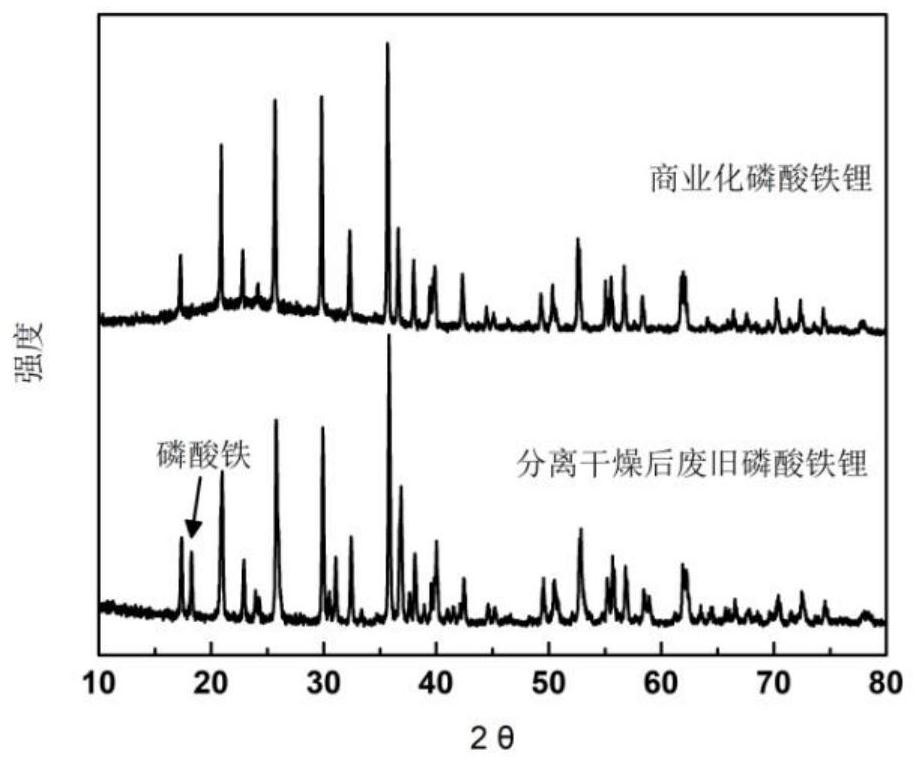

[0037] 1) Firstly, after the recycled lithium iron phosphate waste battery is fully discharged, the open circuit voltage after discharge is 0.8V, and then disassembled to take out the positive plate (the content of lithium iron phosphate is 84.6%, and the content of aluminum is 12.1%);

[0038] 2) Wash the positive electrode sheet with dimethyl carbonate, remove the residual electrolyte on the positive electrode sheet, and place the positive electrode sheet from which the residual electrolyte solution has been removed in a vacuum oven at 80°C to dry;

[0039]3) Accurate step 2) weigh 3g of the obtained positive electrode sheet, put it into 100ml of stearic acid mass fraction of 1% water dispersion, in order to further accelerate mass transfer, cut the positive electrode sheet into a size of 2cm × 2cm, and adjust the rotation speed to 500r / min, stirring at 25°C for 5min;

[0040] 4) Sieve the current collector aluminum out of the final mixture obtained in step 3) using a 40-mes...

Embodiment 2

[0043] All the other are the same as Example 1, except that the mass fraction of stearic acid is 3%.

Embodiment 3

[0045] All the other are the same as Example 1, except that the mass fraction of stearic acid is 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com