A process for deep purification and impurity removal of wet zinc leaching solution

A deep purification, purification and impurity removal technology, applied in the direction of improving process efficiency, can solve the problems that calcium sulfate cannot effectively convert calcium sulfide, generate solid waste, and high raw material costs, so as to reduce the production of secondary pollutants and reduce purification treatment. The effect of low cost and secondary pollution risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

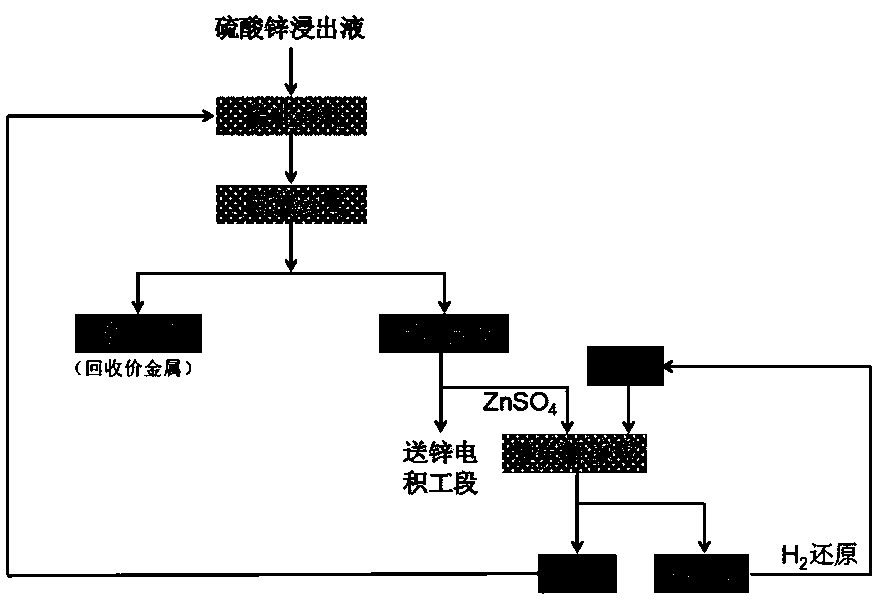

[0034] A process for deep purification and impurity removal of wet zinc leaching solution, the process flow chart is as follows figure 1 shown, including the following steps:

[0035] (1) Place commercially available barium sulfate in a reduction furnace, pass through hydrogen gas, and carry out reduction reaction at a temperature of 850° C. for 1 hour to obtain barium sulfide and water.

[0036] (2) Combine 5.3 kg of barium sulfide (BaS) obtained in step (1) with 30 L of purified ZnSO 4 solution (the "purified ZnSO 4 "solution" comes from the zinc smelting enterprise's own production process after purification and removal of impurities and contains zinc sulfate after purification) mixed for metathesis reaction, solid-liquid separation, to obtain zinc sulfide solution and barium sulfate, the concentration of ZnS in the prepared zinc sulfide solution It is 120g / L.

[0037] In this step (2), the barium sulfate produced during the preparation of the zinc sulfide solution can b...

Embodiment 2

[0046] A process for deep purification and impurity removal of wet zinc leaching solution, the process flow chart is as follows figure 1 shown, including the following steps:

[0047] (1) Place commercially available barium sulfate in a reduction furnace, pass through hydrogen gas, and carry out reduction reaction at a temperature of 850° C. for 1 hour to obtain barium sulfide and water.

[0048] (2) Combine 10 kg of barium sulfide (BaS) obtained in step (1) with 30 L of purified ZnSO 4 solution (the "purified ZnSO 4 "solution" comes from the zinc smelting enterprise's own production process after purification and removal of impurities and contains zinc sulfate after purification) mixed for metathesis reaction, solid-liquid separation, to obtain zinc sulfide solution and barium sulfate, the concentration of ZnS in the prepared zinc sulfide solution It is 110g / L.

[0049] In this step (2), the barium sulfate produced during the preparation of the zinc sulfide solution can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com