Spray paint for artificial turf and preparation method thereof

An artificial turf and inkjet technology, applied in epoxy resin coatings, reflective/signal coatings, antifouling/underwater coatings, etc., can solve problems such as affecting heat transfer, breeding bacteria, and easy to adhere to dust, so as to avoid agglomeration, Enhance heat dissipation effect, not easy to adhere to the effect of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: a kind of artificial turf spray paint, comprises A component and B component, and the raw material of described A component and corresponding parts by weight thereof are as shown in table 1, and wherein, inorganic heat-conducting filler is nano-nitrided Aluminum, organic thermal conductive filler is carbon fiber, silane coupling agent is γ-aminopropyltrimethoxysilane, additive is defoamer, specifically emulsified silicone oil, solvent is toluene, epoxy resin is bisphenol A type epoxy resin .

[0043] A preparation method for spray paint for artificial turf, comprising the following steps:

[0044] Step 1, adding the corresponding parts by weight of the inorganic heat-conducting filler and the organic heat-conducting filler into half the part by weight of the solvent, ultrasonically dispersing evenly, then adding a silane coupling agent, dispersing evenly, and obtaining the first mixture;

[0045] Step 2, uniformly mixing the corresponding weight fractions...

Embodiment 2-3

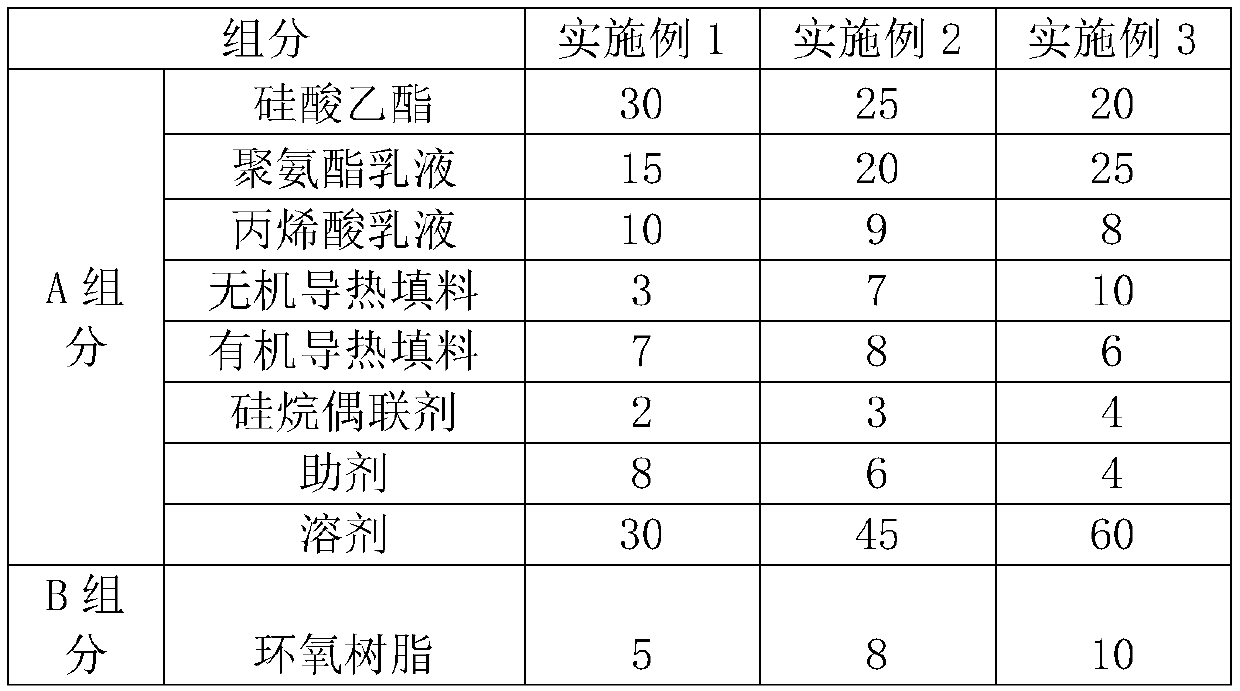

[0047] Example 2-3: A spray paint for artificial turf, the difference from Example 1 is that the components of the raw materials and their corresponding parts by weight are shown in Table 1.

[0048] Each component of the raw material of table 1 embodiment 1-3 and parts by weight thereof

[0049]

Embodiment 4

[0050] Embodiment 4: A spray paint for artificial turf, the difference from Embodiment 1 is that the inorganic heat-conducting filler is nano-alumina.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com