Solid slow-release carbon source for biological denitrification nitrogen removal and preparation method thereof

A slow-release carbon source, nitrification and denitrification technology, which is applied in the field of water treatment, can solve the problems of poor slow-release effect and achieve the effect of low cost, wide source of raw materials and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 Preparation of solid slow-release carbon source

[0025] (1) Add 10 g of potato starch and 30 g of polysulfone into an Erlenmeyer flask filled with 60 mL of dimethylacetamide, and put them in a water bath at 80°C and stir for 24 h to mix the starch and polysulfone evenly. Then pour the above solution into a mold with a side length of 1.5 cm, and then immerse the mold in deionized water for 1 hour to obtain a carbon source with a preliminary shape;

[0026] (2) The above-mentioned carbon source was immersed in deionized water for 2 days to complete the phase inversion process. The deionized water was replaced every day, and then the carbon source was taken out and dried at 60°C for 2 h to obtain sample No. 1, which was stored in an oxygen barrier for later use;

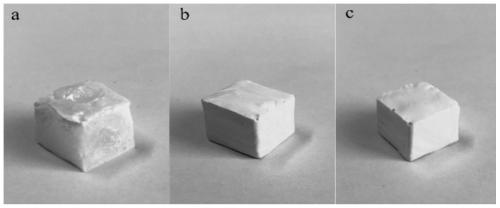

[0027] Samples No. 2 (starch: polysulfone = 1:1, 40 g) and No. 3 (starch: polysulfone = 3:1, 40 g) were prepared in the same way. Different samples were prepared such as figure 1 Shown: a is sample N...

Embodiment 2

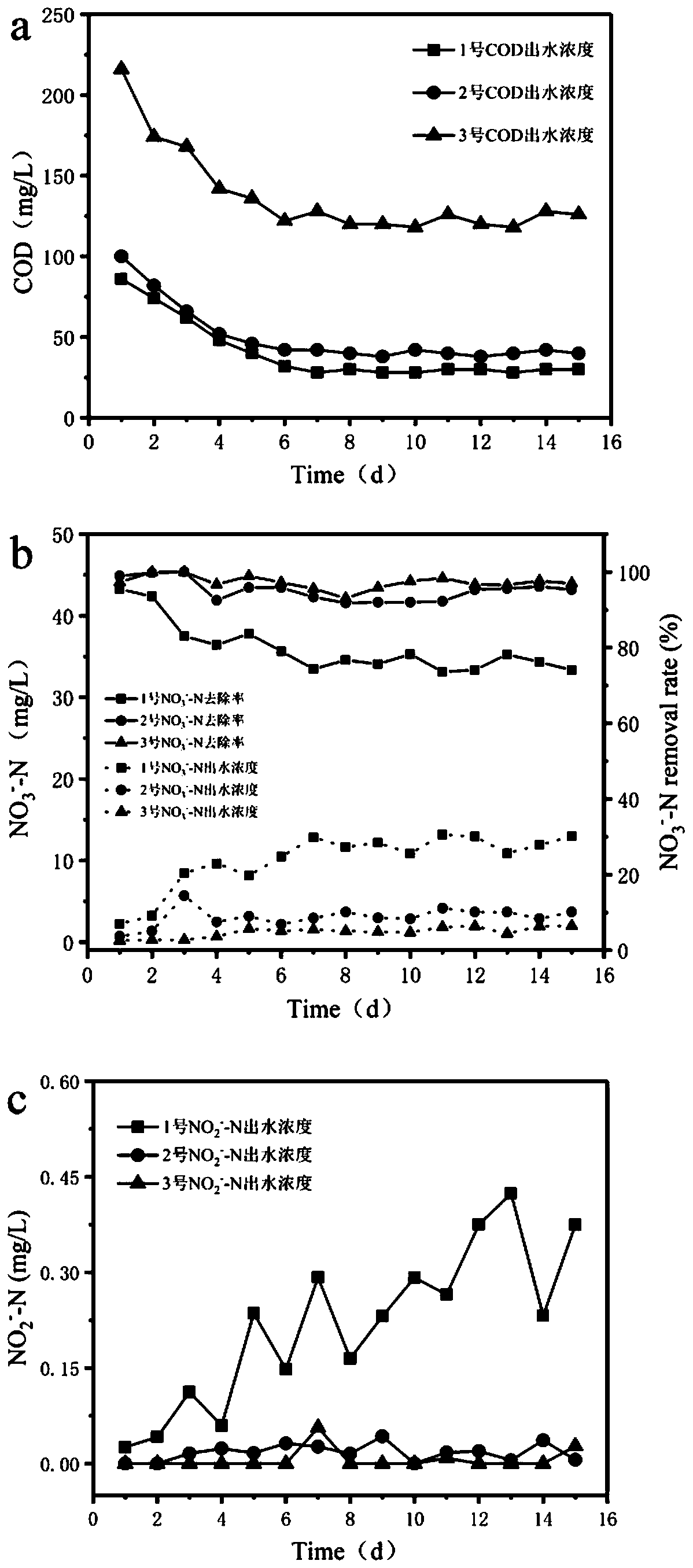

[0028] Example 2 The removal effect of solid slow-release carbon source on nitrate nitrogen

[0029] Add 10 g of No. 1, No. 2 and No. 3 carbon sources into a 500 mL Erlenmeyer flask and add 500 mL of synthetic waste water (50 mg / L NO 3 - -N, 1 mg / L TP) and activated sludge with a final concentration of 800 mg / L. Place the flask in a shaking incubator set at 80 rpm and 25 °C. Take water samples every 24 hours for COD, NO 3 - -N and NO 2 - -N concentration measurement and at the same time replace the synthetic waste water in the flask.

[0030] Referring to "Water and Wastewater Monitoring and Analysis Methods" (Editorial Committee of "Water and Wastewater Monitoring and Analysis Methods" of the State Environmental Protection Administration. Water and Wastewater Monitoring and Analysis Methods [M]. 4th Edition. Beijing: China Environmental Science Press, 2002), NO was measured at 220 nm and 275 nm with a UV spectrophotometer (Shimadzu UV-3100) 3 - -N, use naphthalene et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com