Plasma etching apparatus member having improved plasma-resistant properties and manufacturing method therefor

An etching device and plasma technology, which is applied in the field of plasma characteristics, can solve the problems of uneconomical ratios of different types of elements, and achieve simple deposition and heat treatment, minimized possibility of process parameter changes, and reasonable time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 3

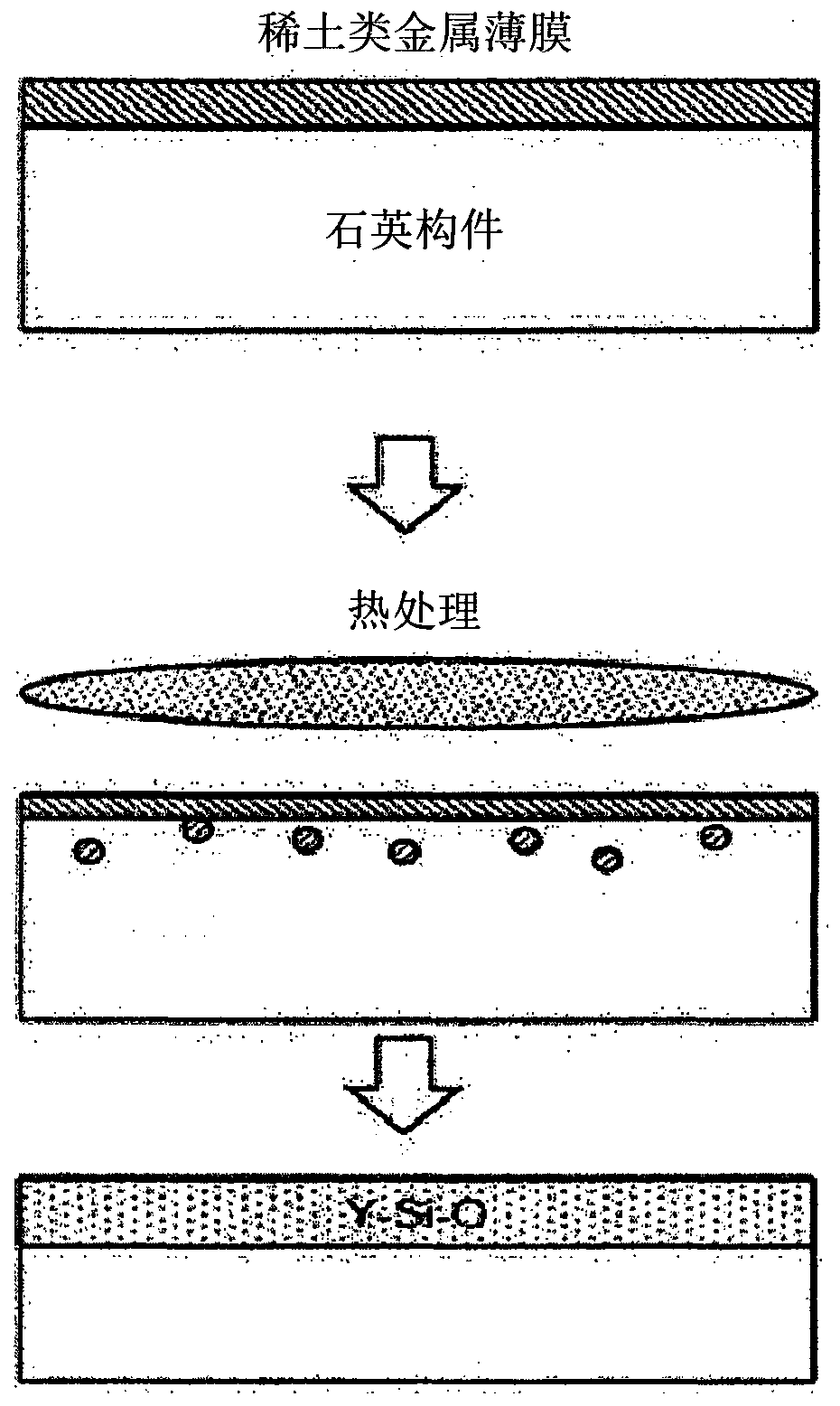

[0076] Examples 1 to 3 Yttrium metal thin films were produced under the configuration and conditions described in Table 1 below.

[0077] [Table 1]

[0078]

[0079] In order to analyze the element distribution of the examples, the following experiments were performed.

experiment example 1- 2

[0080]

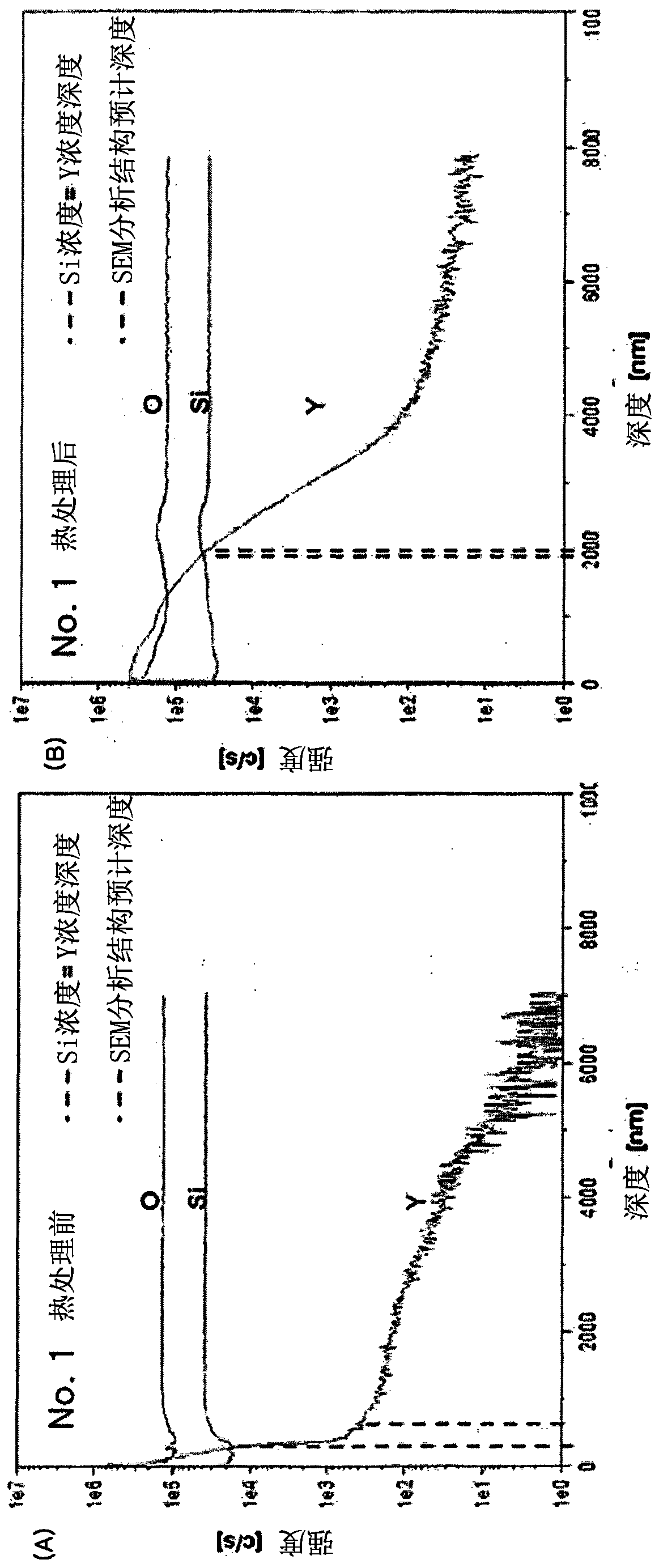

[0081] The depth of thermal diffusion of the yttrium (Y) element in Examples 1 and 2 was evaluated using a secondary ion mass spectrometer (hereinafter referred to as "SIMS"). First, in order to minimize the exposure of the sample protective film to the atmosphere, the sample is placed in a purge system, a part of the protective film of the sample is collected, and added to the SIMS analysis sample holder (sample holder). While maintaining a purge state, place the sample rack in the preparation chamber of the SIMS device, pump the preparation chamber, and place it in the experimental chamber. ), using an oxygen ion gun (oxygen ion gun), quantitative analysis of yttrium (Y), silicon (Si) and oxygen (O) content, to obtain a depth profile graph (depth profile graph).

[0082] The depth curves of Example 1 and Example 2 are shown in image 3 and Figure 4 . This takes into consideration that the positive ionization characteristics of each element are superior to the...

experiment example 2

[0086]

[0087] Using X-ray photoelectron spectroscopy (XPS) (Thermo Fisher Scientific, using Al Kα (1486.6eV) X-ray light source), the chemical bonding state and atomic content of the test pieces before and after plasma treatment were investigated. The basic pressure of the test piece chamber is adjusted to 10 -9 Torr, in the analysis, holds 10 -9 ~10 -7 support range. The measured spectrogram is displayed as a plot of electron binding energy versus electron number for a fixed, small-energy interval. Peak area and peak height sensitivity coefficients were used for quantification. All surface compositions shown here are expressed in atomic % (atm%).

[0088] like Figure 5 As shown, the Y three-dimensional orbit shows Y 3d3 / 2 and 3d5 / 2 peaks by means of L-S coupling. When yttrium oxides are formed, 3d oxide peaks are generated at lower binding energy positions due to chemical shifts. exist Figure 5 In (B), the Y 3d oxide peak appears on the surface after heat treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com