GaAs-based high-power laser preparation method

A technology of high-power lasers and equipment, applied in the direction of lasers, laser components, semiconductor lasers, etc., can solve problems that affect the reliability and life of semiconductor lasers, chip thermal damage, etc., to ensure current expansion and optical characteristics, improve reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

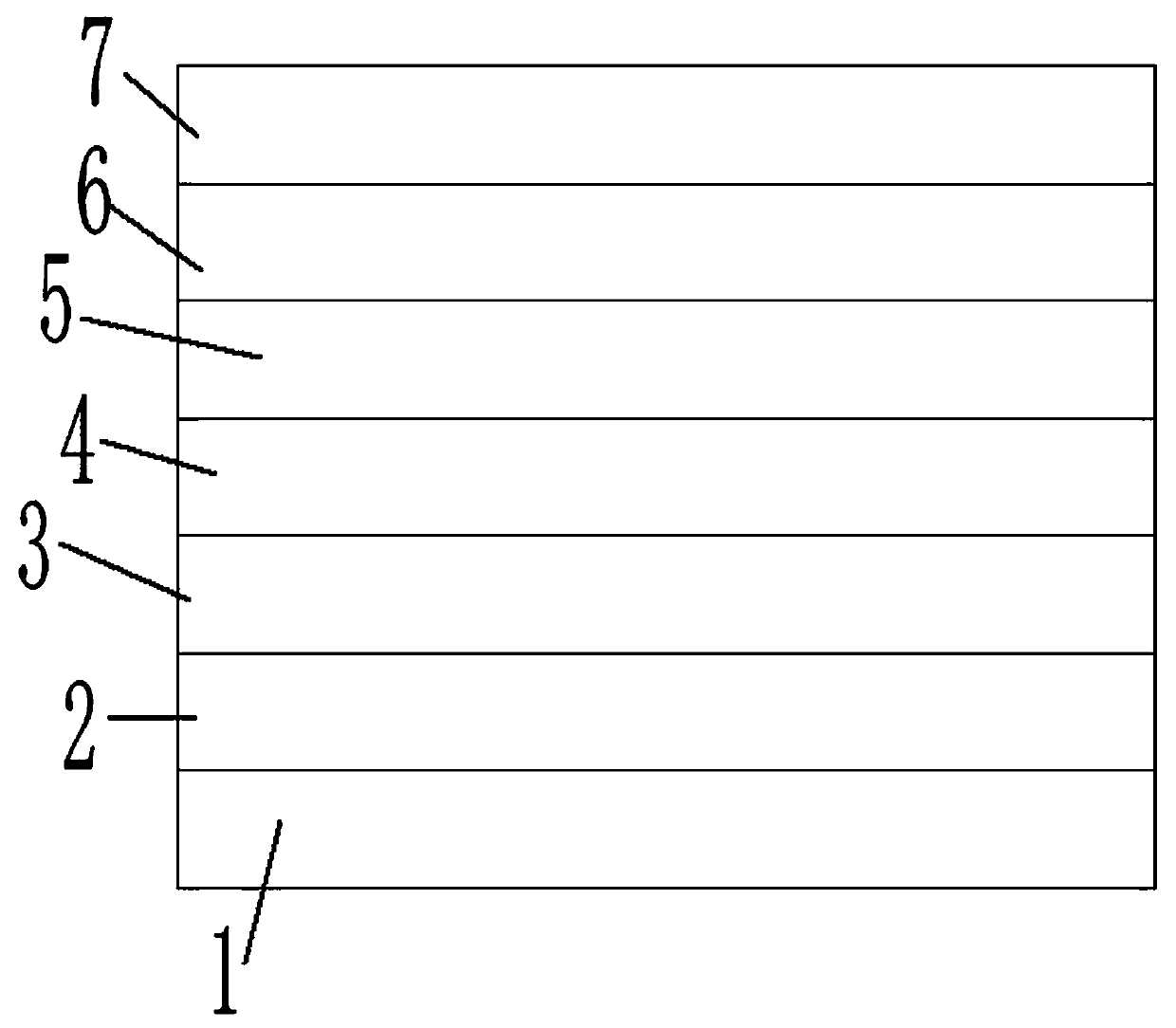

[0034] A method for preparing a GaAs-based high-power laser, comprising the steps of:

[0035] a) The GaAs substrate is placed in the growth chamber of the MOCVD equipment, baked in an H2 gas environment, and AsH3 gas is fed after baking to remove water and oxygen on the surface of the substrate to complete the surface treatment;

[0036] b) Lower the temperature to 750±20°C, pass the AsH3 gas and then pass the TMAl gas with the defined composition, stop the TMAl gas and pass the TMGa gas with the defined composition after an interval of 1-5 seconds, with an interval of 1-10 seconds Seconds later, stop feeding AsH3 gas and TMGa gas to stop growth for 1-50s;

[0037] c) Repeat step b) until a GaAs low-temperature buffer layer 1 with a specified thickness is grown on the substrate;

[0038] d) Keep the temperature at 750±20°C, pass the AsH3 gas and then pass the TMAl gas with the defined composition, stop the TMAl gas after an interval of 1-5 seconds and pass the TMGa gas with ...

Embodiment 1

[0052] The temperature during baking in step a) is 800±20° C., and the baking time is 30 minutes.

Embodiment 2

[0054] The thickness of the GaAs low-temperature buffer layer 1 in step c) is 50-500 nm. The doping concentration is 1E17-5E18 atoms / . Preferably, the GaAs low-temperature buffer layer 1 has a thickness of 100 nm and a doping concentration of 1E18 atoms / .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com