Flexible self-supporting ZnO ultraviolet detector and preparation method thereof

An ultraviolet detector and self-supporting technology, applied in the field of ultraviolet detection, can solve the problems of limiting the preparation of flexible devices, the flexible substrate is not resistant to high temperature, and the material cannot be directly prepared, and achieves simple and efficient response speed, fast response speed, and preparation. Process controllable and designable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

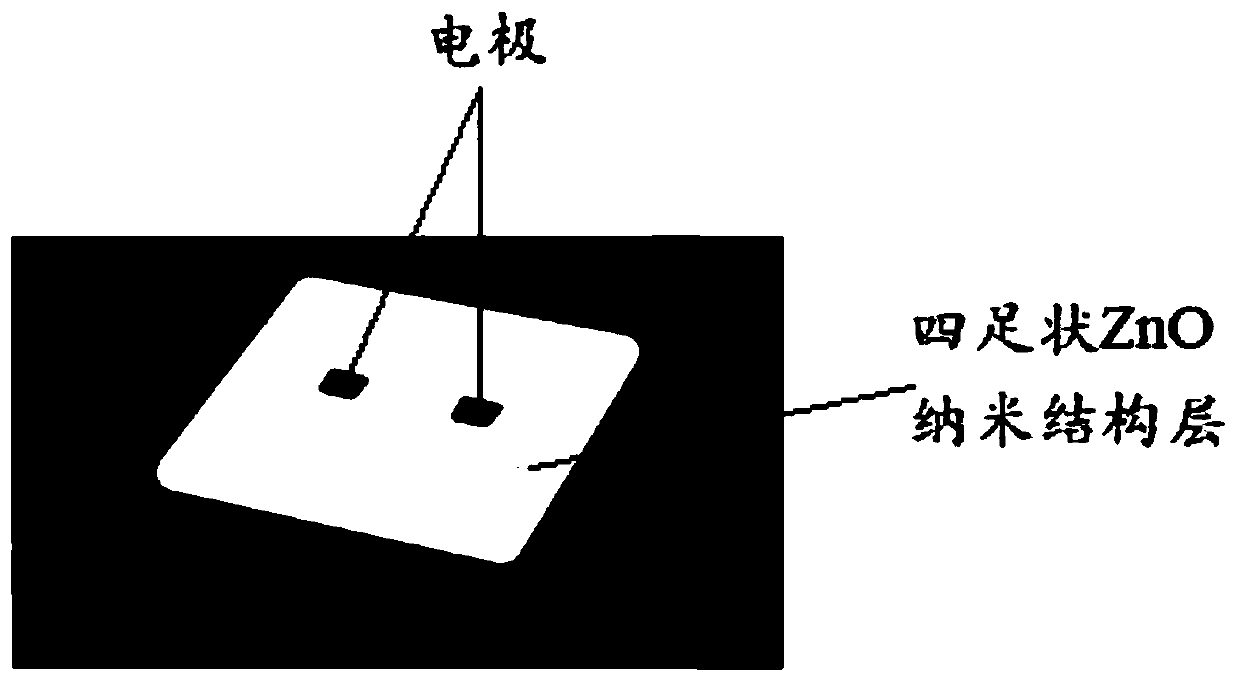

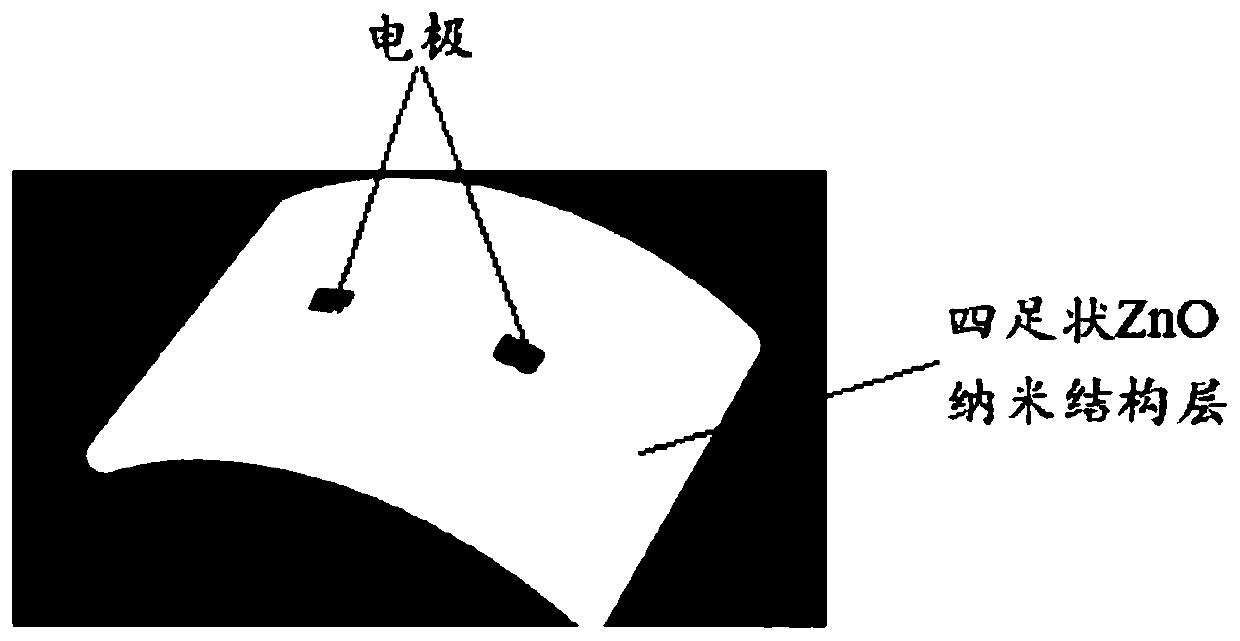

[0041] The present invention also provides a method for preparing the above-mentioned flexible self-supporting ZnO ultraviolet detector, comprising the following steps:

[0042] S1: preparing the tetrapod ZnO nanostructure layer;

[0043] S2: fixing the two electrodes on the tetrapod ZnO nanostructure layer by bonding;

[0044] S3: Transfer the tetrapod ZnO nanostructure layer bonded with the two electrodes to the flexible substrate, and compact and fix it. Before compacting, spread sulfuric acid paper to avoid the tetrapod ZnO nanostructure layer. The structural layer is damaged and contaminated during the compaction process, and a flexible self-supporting ZnO ultraviolet detector is obtained.

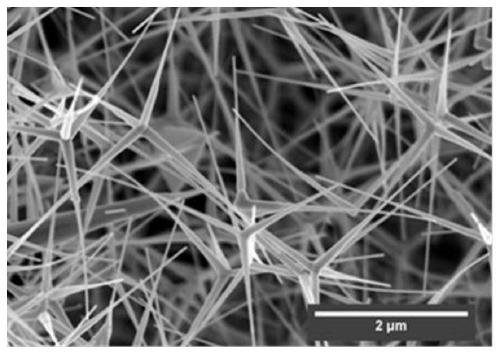

[0045] Wherein, the method for preparing the tetrapod ZnO nanostructure layer in the step S1 is any one of flame transmission method, chemical vapor deposition method and hydrothermal method. When adopting chemical vapor deposition to prepare the tetrapod ZnO nanostructure layer, the ...

Embodiment 1

[0052] The preparation method of the flexible self-supporting ZnO ultraviolet detector of an embodiment of the present invention comprises the following steps:

[0053] S1: preparing the tetrapod ZnO nanostructure layer, the specific steps are:

[0054] S10: Grinding and mixing ZnO powder and graphite powder uniformly at a mass ratio of 1:1, and then placing them in a chemical vapor deposition device as a growth source;

[0055] S11: Under the protection of argon, the chemical vapor deposition equipment is heated up. The temperature rise control parameters are: 50min from room temperature to 1000°C, 30min from 1000°C to 1150°C; when the temperature rises to about 1000°C, oxygen is introduced , control the oxygen flow rate to 16sccm;

[0056] S12: keeping the temperature at 1150° C. for 60 minutes for growing and depositing tetrapod ZnO nanostructures;

[0057] S13: After the deposition is completed, the temperature is lowered to room temperature, and the tetrapod-shaped ZnO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com