Hydraulic radiating system, hydraulic system of riser suspension device and radiating method

A heat dissipation system and hydraulic technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, servo motors, etc., can solve the problems of difficult operation, inability to arrange, high price, etc., to reduce volume and cost, heat dissipation good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

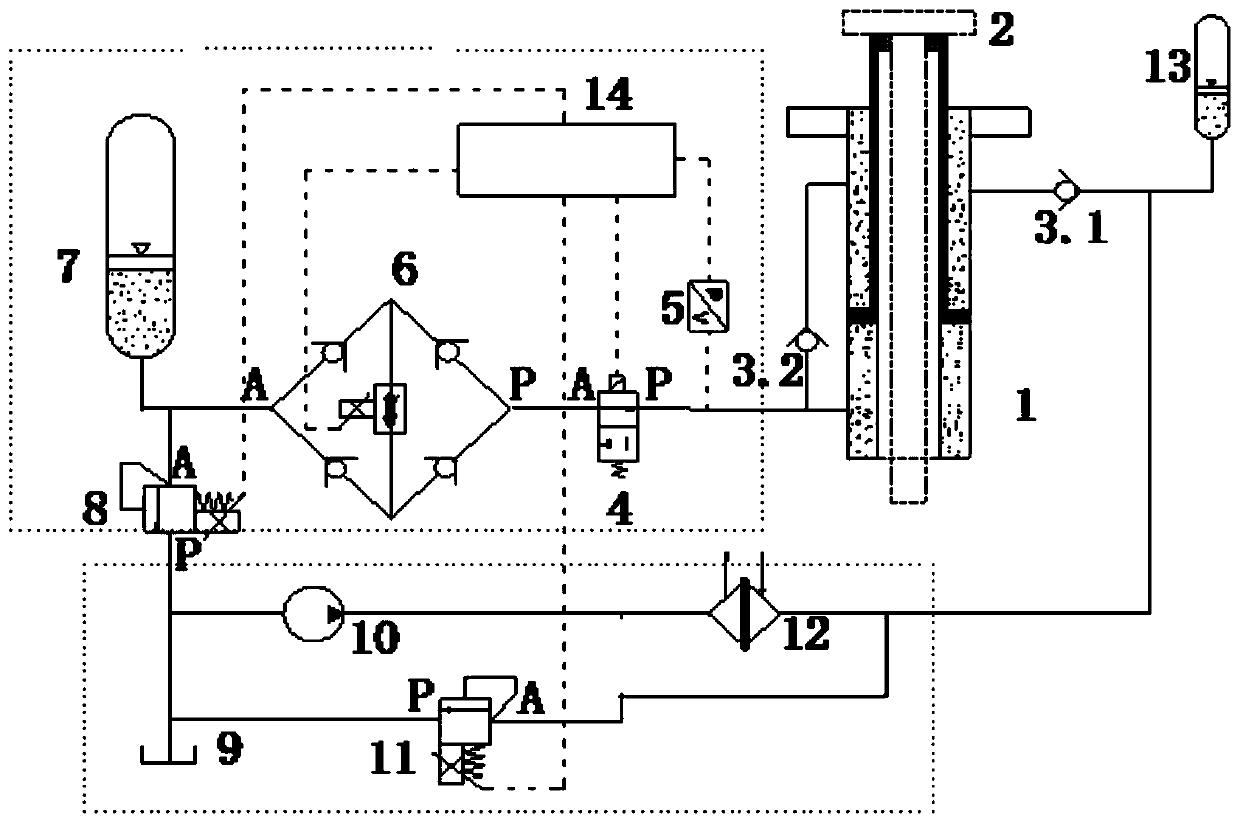

[0034] According to an embodiment of the present invention, the low-pressure circuit further includes a low-pressure relief valve 11 and a fuel tank 9, the fuel tank 9 and the high-pressure relief valve 8, the hydraulic pump 10, and the low-pressure relief valve 11 Both are connected, and the low-pressure relief valve 11 is connected with the low-pressure accumulator 13 and the second one-way valve 3.1.

[0035] According to an embodiment of the present invention, the oil tank 9 is connected in series with the low pressure relief valve 11, the hydraulic pump 10 and the cooler 12 are connected in series, and the oil tank 9 is connected with the low pressure relief valve 11 in series. The connecting line is connected in parallel with the line connecting the hydraulic pump 10 and the cooler 12.

[0036] According to an embodiment of the present invention, the high-pressure circuit further includes a shut-off valve 4, one end of the shut-off valve 4 is connected to the throttle block 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com