Polyvinyl alcohol-based composite powder for selective laser sintering and preparation method thereof

A polyvinyl alcohol-based, composite powder technology, applied in the direction of additive processing, etc., can solve the problems affecting the performance of sintered parts, affecting the performance of 3D printing products, and limited application fields, etc., to achieve good biodegradability, The effect of low manufacturing cost and mature process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

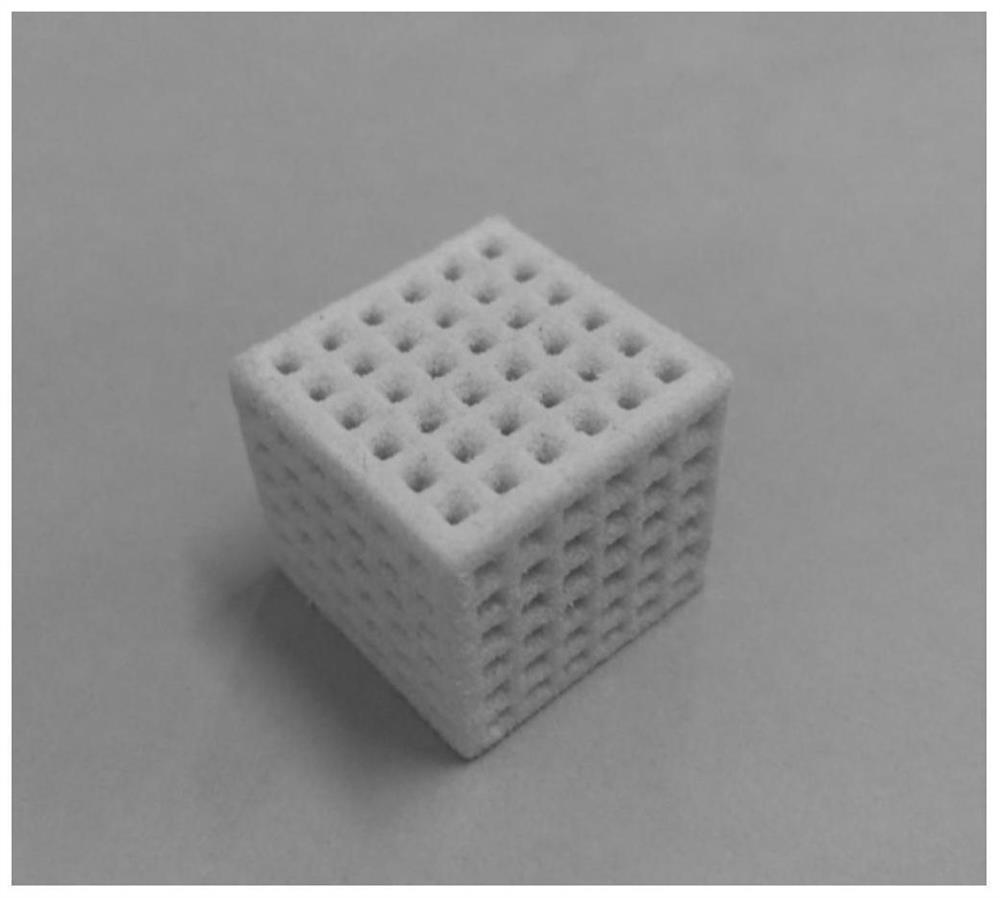

Examples

Embodiment 1

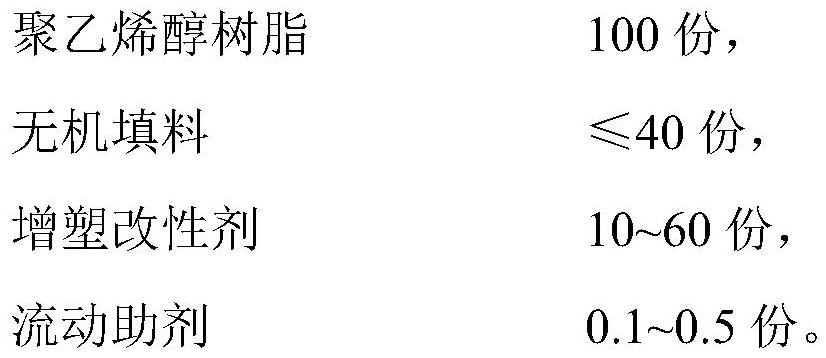

[0043] The preparation method of polyvinyl alcohol / hydroxyapatite composite powder for selective laser sintering, in parts by weight, comprises the following steps:

[0044] (1) Add 100 parts of polyvinyl alcohol resin, 30 parts of glycerin, and 3 parts of magnesium nitrate into a high-speed mixer at room temperature (20-30°C), mix at 100r / min for 30 minutes, then put it in a sealed box and seal it , and then place the sealed box in an oven at 80°C for 12 hours to make it fully plasticized, then add 30 parts of hydroxyapatite and then fully stir to make it evenly mixed;

[0045] (2) Melt and blend the mixture obtained in step (1) with a twin-screw extruder, and extrude to granulate; the extrusion processing parameters are: 80°C in the first zone, 180°C in the second zone, and 190°C in the third zone. The temperature is 179°C, and the screw speed is 35r / min;

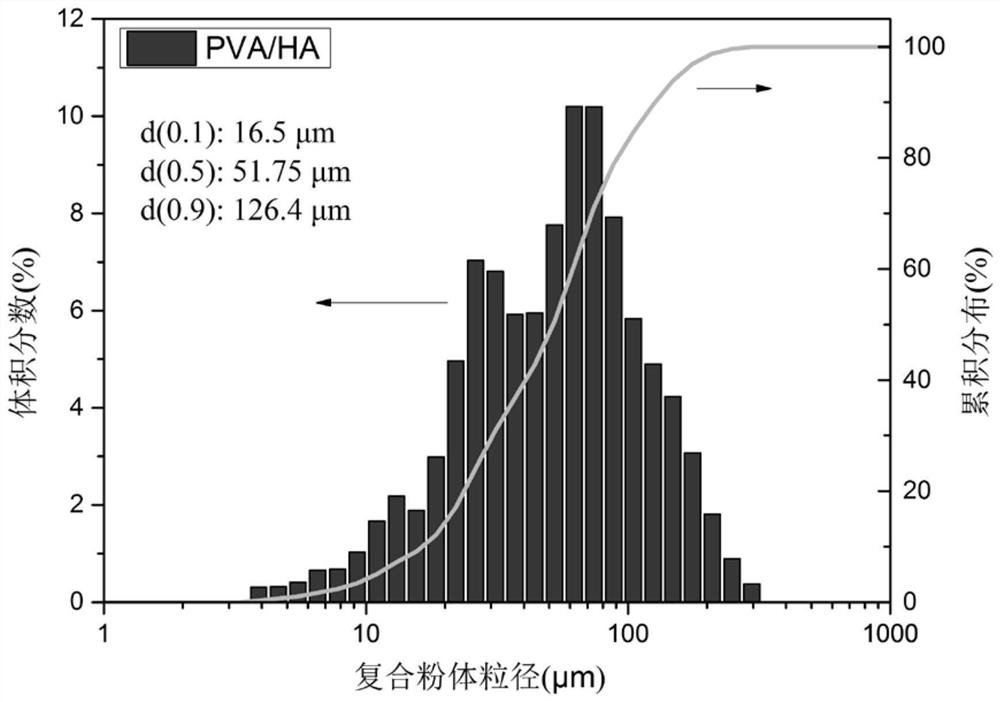

[0046] (3) The granules obtained in step (2) are subjected to cryogenic crushing with a freeze pulverizer at a tempera...

Embodiment 2

[0051] The preparation method of polyvinyl alcohol / tricalcium phosphate (TCP) composite powder for selective laser sintering, in parts by weight, comprises the following steps:

[0052] (1) Add 100 parts of polyvinyl alcohol resin, 25 parts of glycerol, and 2 parts of starch into a high-speed mixer at room temperature (20-30°C), mix for 30 minutes at 100 r / min, put it in a sealed box, and seal it. Then place the sealed box in an oven at 80°C for 12 hours to make it fully plasticized, and then add 40 parts of tricalcium phosphate to fully stir and mix to make it evenly mixed;

[0053] (2) Melt and blend the mixture obtained in step (1) with a twin-screw extruder, and extrude to granulate; the extrusion processing parameters are: 1 zone 80°C, 2 zone 185°C, 3 zone 190°C, head The temperature is 175°C, and the screw speed is 30r / min;

[0054] (3) The granules obtained in step (2) are cryogenically crushed using a freezer pulverizer at a temperature of -100°C, and then the resulti...

Embodiment 3

[0059] The preparation method of polyvinyl alcohol / carbon nanotube composite powder for selective laser sintering, in parts by weight, comprises the following steps:

[0060] (1) At room temperature (20-30°C), add 100 parts of polyvinyl alcohol resin, 10 parts of glycerol, 10 parts of water, and 5 parts of 1-hydroxyethyl-3-methylimidazolium chloride into the high-speed mixer , mixed at 200r / min for 40min, put it into a sealed box and sealed it, then placed the sealed box in a 60°C oven for 8 hours to make it fully plasticized, and then added 1 part of carbon nanotubes for full stirring and mixing to make it mix Uniform;

[0061] (2) Melt and blend the mixture obtained in step (1) with a twin-screw extruder, and extrude to granulate; the extrusion processing parameters are: 60°C in the first zone, 170°C in the second zone, and 180°C in the third zone. The temperature is 160°C, and the screw speed is 40r / min;

[0062] (3) Cryogenically pulverize the pellets obtained in step (2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com