Preparation method and application of urea modified starch

A starch and urea technology, applied in the field of preparation of urea-modified starch, can solve problems such as cost increase, and achieve the effects of overcoming long time consumption, simple process, and improved water dispersibility and suspension performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

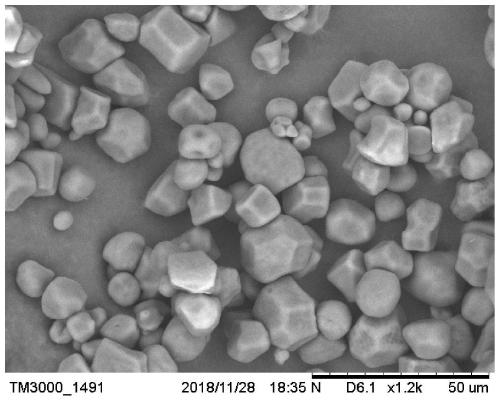

Embodiment 1

[0033] Accurately weigh 10g of urea, add 30g of water, then add 5g of cornstarch, stir for about 1h, filter and then freeze-dry at -40°C for 48h; take out the dry matter and pulverize it, put it in a flask and heat it to 65°C in an oil bath and keep it warm 48h. The product was cooled to room temperature, washed three times with water, and then dried in vacuum to obtain the urea-modified starch, which was observed under a scanning electron microscope as follows: figure 1 Shown, and the elemental analyzer test nitrogen content is 0.07%.

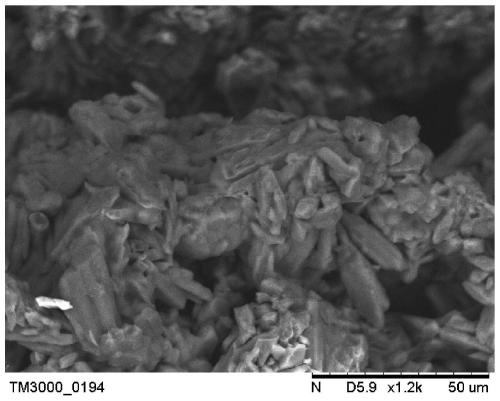

Embodiment 2

[0035] Accurately weigh 10g of urea, add 30g of water, then add 5g of cornstarch, stir for about 1h, filter and then freeze-dry at -40°C for 48h; take out the dry matter and pulverize it, put it in a flask for microwave irradiation heating, and the microwave power is 240W, microwave irradiation heating time is 1min; the product is cooled to room temperature, washed three times with water, and after vacuum drying, the urea-modified starch is obtained, and observed under a scanning electron microscope as follows: figure 2 Shown, and the nitrogen content is 1.26% as tested by elemental analyzer.

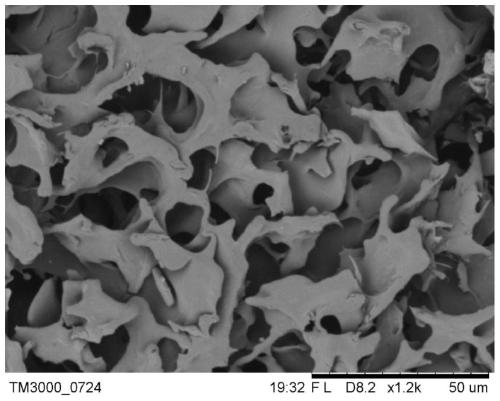

Embodiment 3

[0037] Accurately weigh 15g of urea, add 30g of water, then add 5g of potato starch, stir for about 1h, filter and then freeze-dry at -40°C for 48h; take out the dry matter and pulverize it, put it in a flask for microwave irradiation heating, and the microwave power is 780W, microwave irradiation heating time is 3min; the product is cooled to room temperature, washed three times with water, and after vacuum drying, the urea-modified starch is obtained, and observed under a scanning electron microscope as follows: image 3 Shown, and the nitrogen content is 6.31% as tested by the elemental analyzer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com