Preparation method of conjugated polymer luminescent material with main chain containing naphthalene derivative

A technology of conjugated polymers and luminescent materials, which is applied in the field of preparation of polymer luminescent materials, can solve the problems of poor chemical stability, low luminous efficiency, and poor moldability of polymers, and achieve short reaction time, high luminous brightness, and reduced The effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Chemical oxidative homopolymerization of 2,3-dioctyloxynaphthalene

[0036]The 250mL three-necked flask is equipped with a condenser tube and a nitrogen inlet tube. Nitrogen is led out from the top of the condenser tube, and connected to the atmosphere through a drying tower filled with calcium chloride. Add 0.385 g (1 mmol) of 2,3-dioctyloxynaphthalene, add 10 mL of chloroform to dissolve the monomer, then add 0.64 (4 mmol) g of anhydrous ferric chloride; stir at 25°C for 24 hours under nitrogen protection Stop the reaction, add 50mL methanol, stir for 2 hours and then filter. After the filter residue was dried, it was extracted with ethanol for 24 hours to obtain 0.31 g of a homopolymer of 2,3-dioctyloxynaphthalene after drying, with a yield of 80.5%.

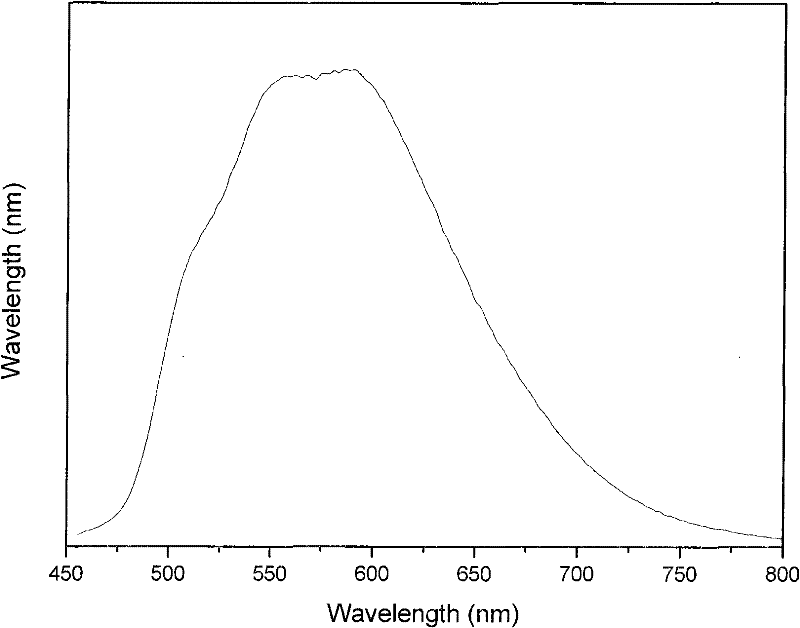

[0037] To 2,3-dioctyloxynaphthalene chemical oxidation homopolymerization luminescent performance test: the chemical oxidation homopolymerization of 2,3-dioctyloxynaphthalene prepared in the embodiment is dissolved i...

Embodiment 2

[0039] Chemical Oxidative Copolymerization of 2,3-Dioctyloxynaphthalene and Triphenylamine

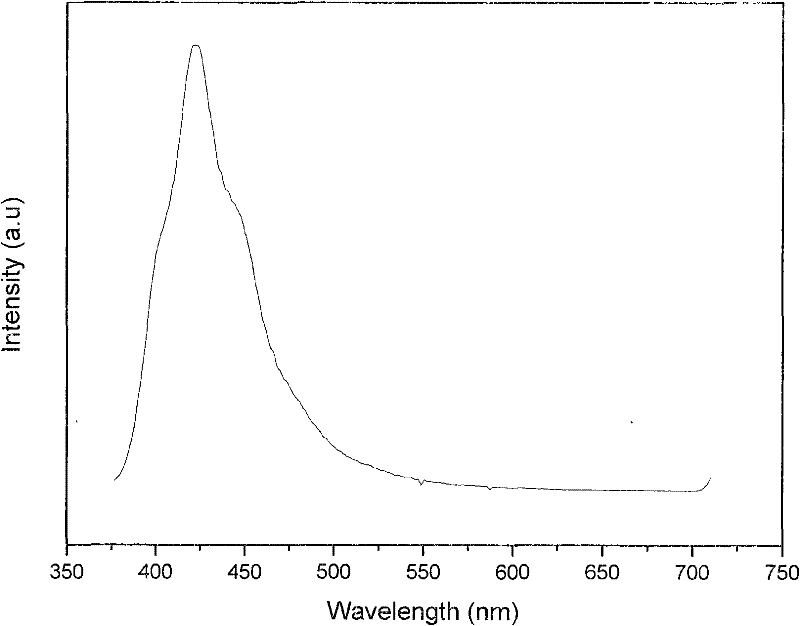

[0040] The 250mL three-necked flask is equipped with a condenser tube and a nitrogen inlet tube. Nitrogen is led out from the top of the condenser tube, and connected to the atmosphere through a drying tower filled with calcium chloride. Add 0.385 g (1 mmol) of 2,3-dioctyloxynaphthalene, 0.25 g (1 mmol) of triphenylamine, add 10 mL of chloroform to dissolve the two monomers, and then add 0.04 (0.25 mmol) g of anhydrous ferric chloride; The reaction was stopped after stirring at 25° C. for 4 hours under the protection of nitrogen, added into 50 mL of methanol, stirred for 2 hours, and then filtered. After the filter residue was dried, it was extracted with ethanol for 24 hours to obtain 0.05 g of a copolymer of 2,3-dioctyloxynaphthalene and triphenylamine after drying, with a yield of 7.9%.

Embodiment 3

[0042] Chemical Oxidative Copolymerization of 2,3-Dioctyloxynaphthalene and Triphenylamine

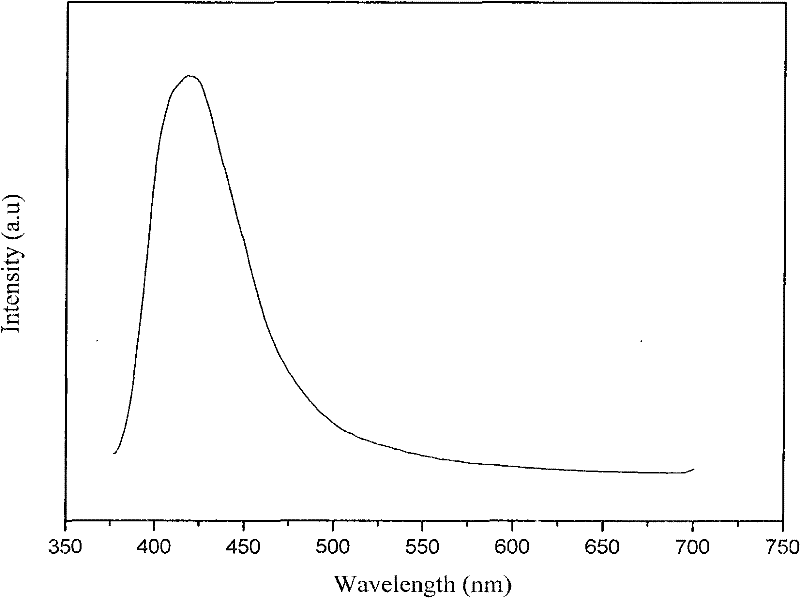

[0043] The 250mL three-necked flask is equipped with a condenser tube and a nitrogen inlet tube. Nitrogen is led out from the top of the condenser tube, and connected to the atmosphere through a drying tower filled with calcium chloride. Add 0.385 grams (1 mmol) of 2,3-dioctyloxynaphthalene, 0.25 grams (1 mmol) of triphenylamine, add 10 mL of chloroform to dissolve the two monomers, and then add 0.04 (0.25 mmol) of anhydrous ferric chloride; After stirring at 25°C for 24 hours under the protection of nitrogen, the reaction was stopped, added into 50 mL of methanol, stirred for 2 hours, and then filtered. After the filter residue was dried, it was extracted with ethanol for 48 hours to obtain 0.13 g of a copolymer of 2,3-dioctyloxynaphthalene and triphenylamine after drying, with a yield of 20.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com