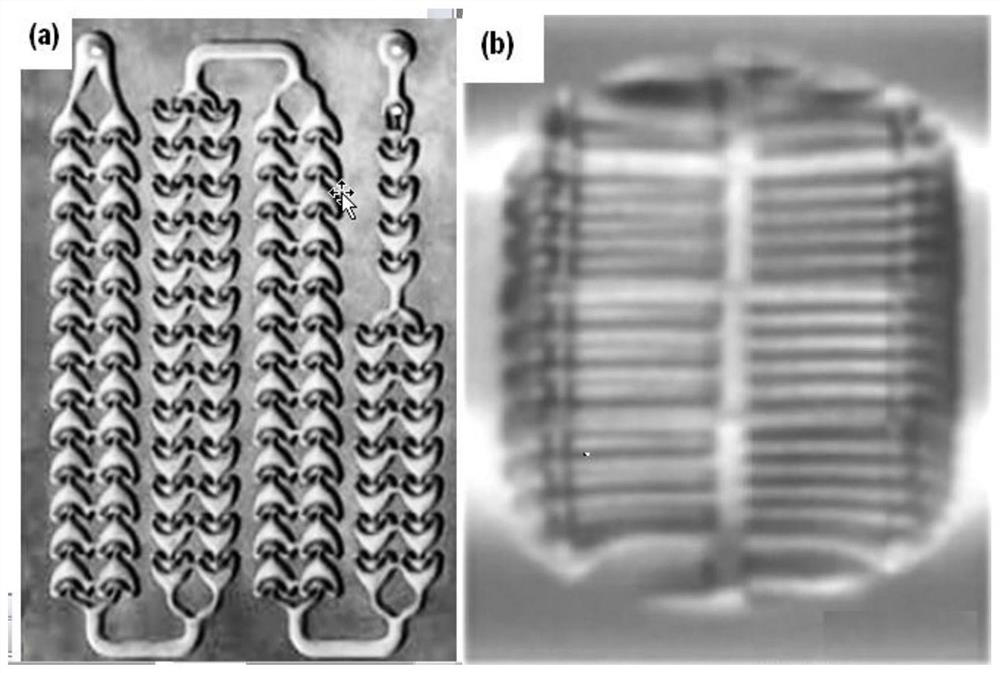

A method for preparing diphenyl ether derivatives by an improved microchannel process

A technology of microchannel and diphenyl ether, which is applied in the preparation of organic compounds, chemical instruments and methods, preparation of amino hydroxyl compounds, etc., can solve the problems of reduced reaction efficiency and achieve the effect of increasing efficiency, improving reaction rate and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

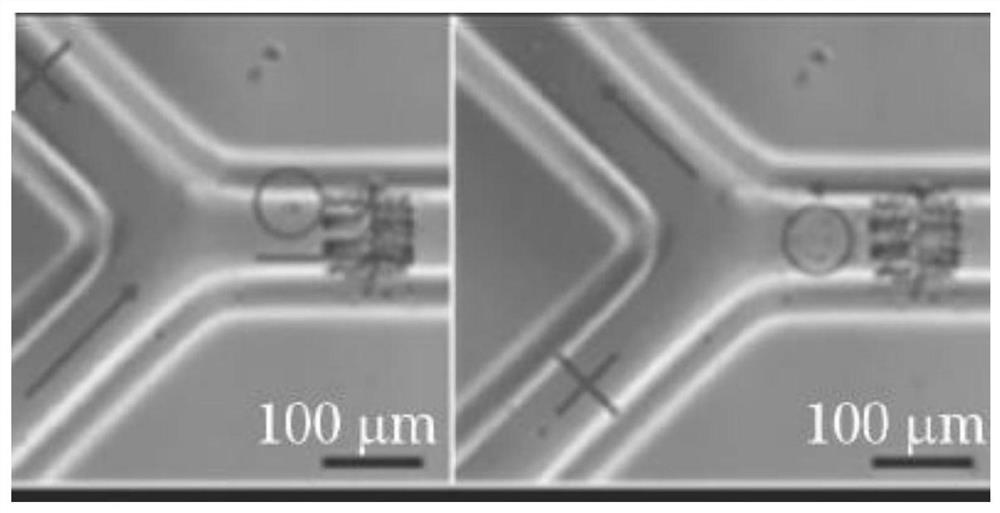

Method used

Image

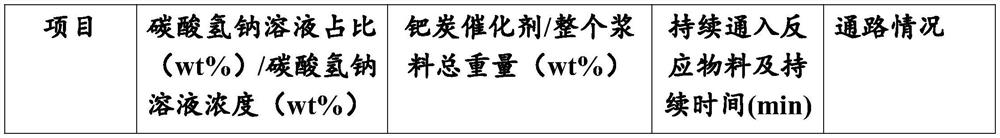

Examples

Embodiment Construction

[0037] Hereinafter, the present invention is described in more detail to facilitate understanding of the invention.

[0038] Before the narration of the specific embodiment, the source of some of the main raw materials used in this description has been explained in the basic situation. It should be noted that the sources of raw materials described in the specific embodiments herein are non-limiting, and those skilled in the art can select appropriate raw materials and testing equipment to carry out related tests and obtain corresponding results according to the inspiration and teaching of the present invention , for raw materials that do not specify specific manufacturers or routes, those skilled in the art are more able to select raw materials that meet the corresponding requirements as the reaction starting material according to the disclosure content and requirements of this specification. If the reaction raw materials for synthesizing some compounds come from the primary p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com