A self-supporting composite electrode

A composite electrode and self-supporting technology, which is applied in the field of electrochemical energy storage, can solve the problems of decreased rate performance, hindering the diffusion of electrolyte ions, etc., to achieve high rate performance, improve rate performance, and increase the effect of mass ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

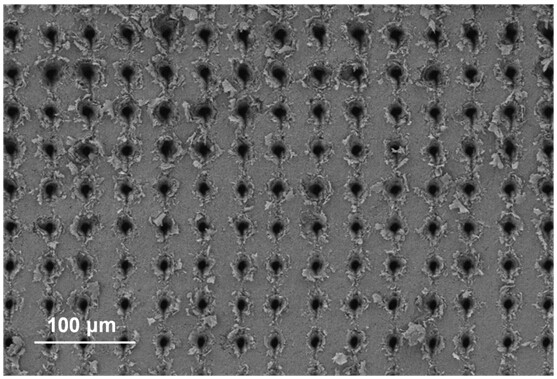

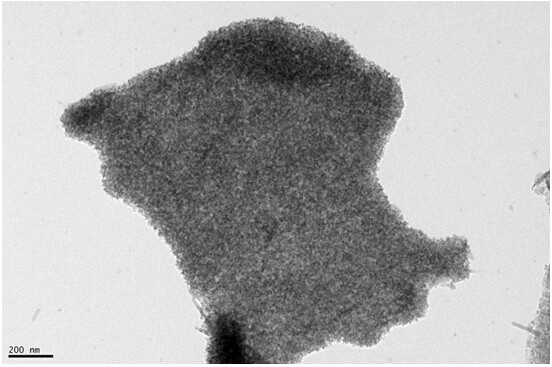

[0023] The self-supporting composite electrode of this embodiment constitutes a conductive support framework with graphene nanosheets, TiO 2 Deposited on the surface of graphene nanosheets, graphene / TiO 2 Composite nanosheets are the structural units in the electrode. They are stacked layer by layer in the direction perpendicular to the electrode surface. The composite nanosheets are mechanically compacted. The pressing pressure is 10Mpa, and the pressing time is 5min. The electrode is still penetrating in the direction perpendicular to the electrode surface. There is an array through-hole structure, the diameter of the through-holes is 10 μm, and the distance between the holes is 40 μm. The array via structure is created by laser drilling method. The scanning electron microscope image of the electrode is shown in image 3 As shown, a vertical via array is shown. Graphene / TiO 2 The transmission electron microscope image of the composite nanosheets is shown in Figure 4 sh...

Embodiment 2

[0027] The self-supporting composite electrode of the present embodiment constitutes the conductive support framework with graphene nanosheets, V 2 o 5 Deposited on the surface of graphene nanosheets, graphene / V 2 o 5 The composite nanosheet is the structural unit in the electrode, which is stacked layer by layer in the direction perpendicular to the electrode surface. The electrode also has an array of through-hole structures in the direction perpendicular to the electrode surface. The aperture of the through hole is 1 μm, and the distance between the holes is 100 μm. .

[0028] The thickness distribution of the graphene nano-sheets is in the range of 0.5-2.0 nm, and the plane radial size of the graphene nano-sheets is distributed in the range of 1.0-10.0 μm.

[0029] The graphene / V 2 o 5 The weight percentage of graphene in the nanosheet self-supporting composite electrode is 30%.

Embodiment 3

[0031] The self-supporting composite electrode of this embodiment uses carbon nanosheets to form a conductive support framework, and the Nb 2 o 5 Deposited on the surface of carbon nanosheets, carbon / Nb 2 o 5 The composite nanosheet is the structural unit in the electrode, which is stacked layer by layer in the direction perpendicular to the electrode surface. The electrode also has an array of through-hole structures in the direction perpendicular to the electrode surface. The aperture of the through hole is 5 μm, and the distance between the holes is 150 μm. .

[0032] The thickness of the carbon nanosheets is distributed in the range of 6.0-20.0 nm, and the plane radial size of the carbon nanosheets is distributed in the range of 7.0-40.0 μm.

[0033] The carbon / Nb 2 o 5 The weight percent content of carbon nanosheets in the nanosheet self-supporting composite electrode is 60%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com