Hot press sintering method of cuprous chloride cathode material for seawater battery

A technology of cuprous chloride and positive electrode materials, applied in battery electrodes, immersion batteries, circuits, etc., can solve the problems of complex preparation process, high production cost, and long process, and achieve simple preparation process, low manufacturing cost, and short process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

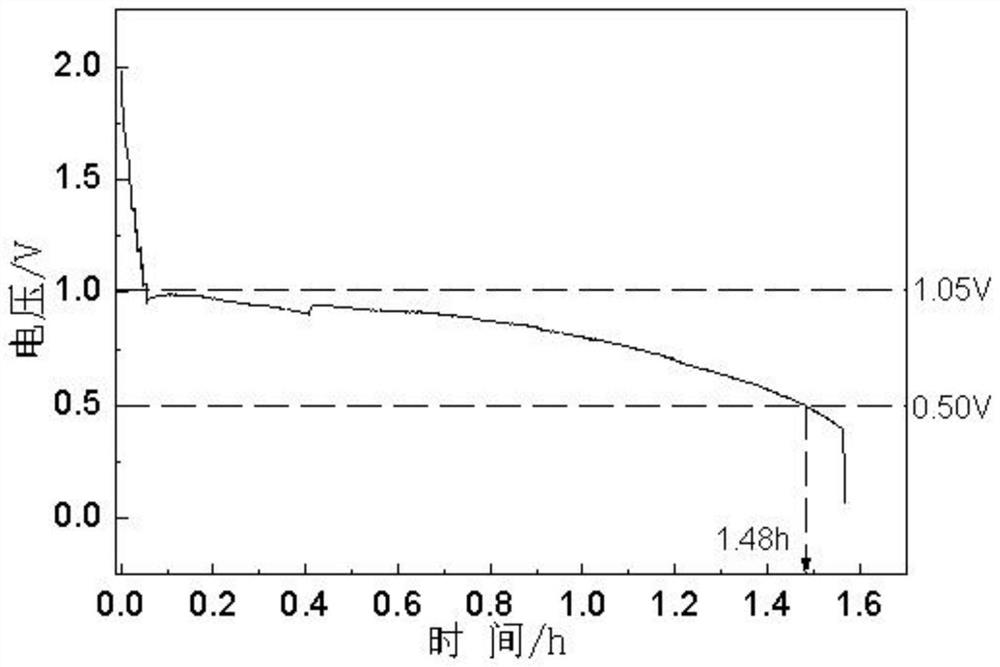

Image

Examples

Embodiment 1

[0027] The hot-pressing sintering method of cuprous chloride cathode material for seawater battery comprises the following steps:

[0028] Step S110, batching, weighing the cuprous chloride powder and the active material powder in a ratio of 95:5 to obtain a premix; the cuprous chloride powder has a particle size of 20 μm to 300 μm, and a powder purity of more than 95%; the active material The powder is a mixture of one or more of copper powder, nickel powder, graphite powder, activated carbon, superconducting carbon black, carbon nanotube, carbon fiber and graphene, the particle size is 10 μm to 200 μm, and the purity is more than 99%;

[0029] Step S120, mixing, placing the premix in a three-dimensional mixer to mix evenly, filling the interior of the mixing cylinder with an inert gas during the mixing process, and mixing uniformly to form a mixture. The mixing time is 30-60 minutes; the mixing cylinder is a plastic mixing cylinder, which is filled with inert gas to prevent ...

Embodiment 2

[0034] The hot-pressing sintering method of cuprous chloride cathode material for seawater battery comprises the following steps:

[0035] Step S110, batching, weighing the cuprous chloride powder and the active material powder in a ratio of 99:1 to obtain a premix; the cuprous chloride powder has a particle size of 20 μm to 300 μm, and a powder purity of more than 95%; the active material The powder is a mixture of one or more of copper powder, nickel powder, graphite powder, activated carbon, superconducting carbon black, carbon nanotube, carbon fiber and graphene, the particle size is 10 μm to 200 μm, and the purity is more than 99%;

[0036] Step S120, mixing, placing the premix in a three-dimensional mixer to mix evenly, filling the interior of the mixing cylinder with an inert gas during the mixing process, and mixing uniformly to form a mixture. The mixing time is 30-60 minutes; the mixing cylinder is a plastic mixing cylinder, which is filled with inert gas to prevent ...

Embodiment 3

[0041] The hot-pressing sintering method of cuprous chloride cathode material for seawater battery comprises the following steps:

[0042]Step S110, batching, weighing the cuprous chloride powder and the active material powder in a ratio of 90:10 to obtain a premix; the cuprous chloride powder has a particle size of 20 μm to 300 μm, and a powder purity of more than 95%; the active material The powder is a mixture of one or more of copper powder, nickel powder, graphite powder, activated carbon, superconducting carbon black, carbon nanotube, carbon fiber and graphene, the particle size is 10 μm to 200 μm, and the purity is more than 99%;

[0043] Step S120, mixing, placing the premix in a three-dimensional mixer to mix evenly, filling the interior of the mixing cylinder with an inert gas during the mixing process, and mixing uniformly to form a mixture. The mixing time is 30-60 minutes; the mixing cylinder is a plastic mixing cylinder, which is filled with inert gas to prevent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com