Novel inorganic-organic material synergistic speed-differential biochemical ball and preparation method thereof

An organic material, rapid separation and biochemical technology, applied in chemical instruments and methods, special compound water treatment, biological water/sewage treatment, etc. The specific gravity of calcium oxide is small, so as to reduce the amount of sludge generated, improve the quality of effluent water, and save the effect of binder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

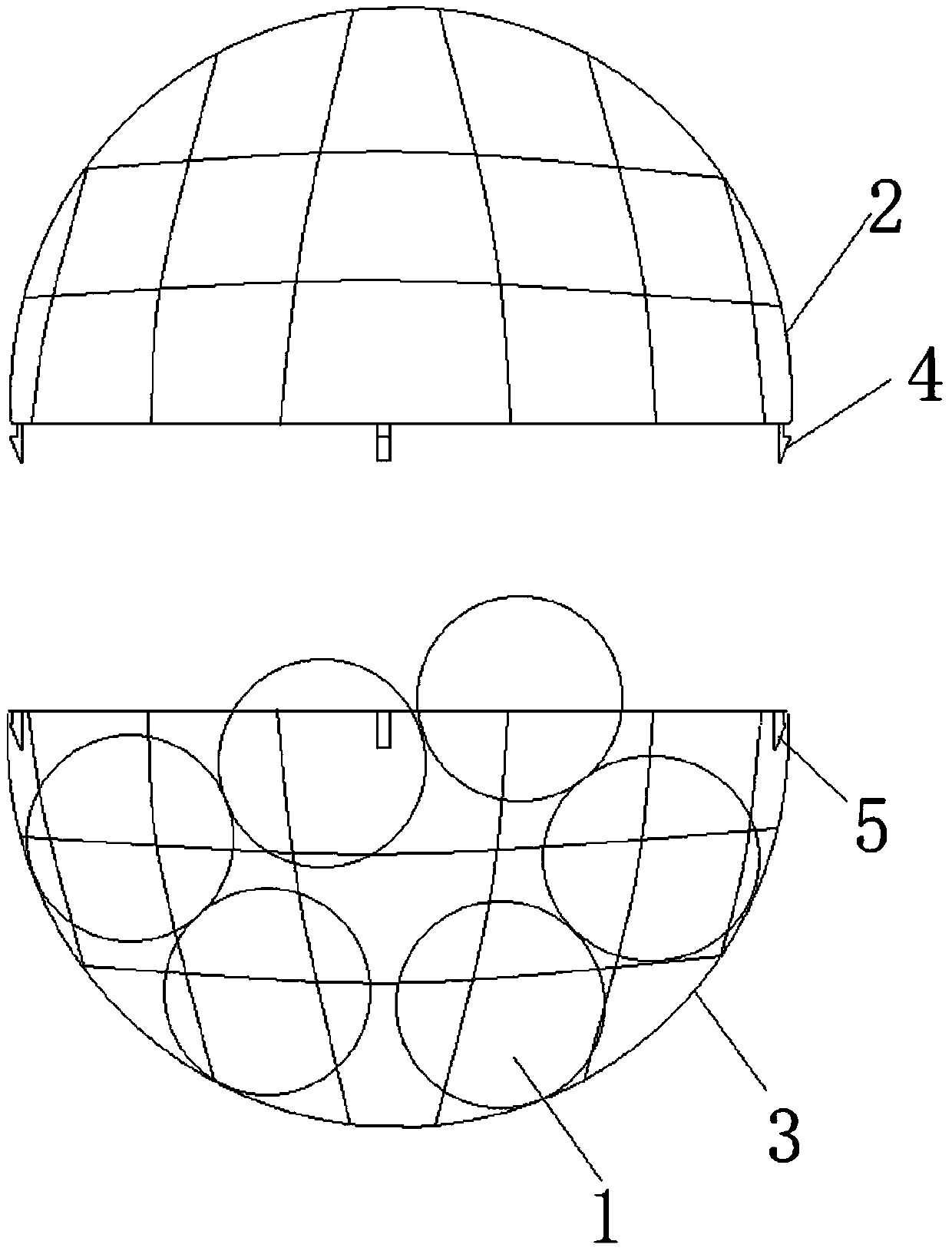

[0031] A new type of inorganic-organic material synergistic quick-dividing biochemical ball, as shown in the figure, includes a filler 1, a hollowed-out net cover 2, and a hollowed-out lower net cover 3, and four barbs 4 are evenly spaced at the bottom of the net cover 2 , the top of the lower net cover 3 is provided with a snap-in slot 5 corresponding to the barb 4, and the net cover 2 and the lower net cover 3 are detachably fastened together through the barb 4 and the snap-in slot 5 to form a hollow with a diameter of 100mm The spherical shell is equipped with composite filler 1, and the spherical shell is made of polyethylene material.

[0032] The preparation method of the novel inorganic-organic material synergistic rapid separation biochemical ball is as follows:

[0033] (1) The adsorption rate is 1%, and the density is 1g / cm 3 The volcanic rock with a wear rate of 0.25, a porosity of 40%, a compressive strength of 1000kgf, and a mechanical strength of 5.08MPa is grou...

Embodiment 2

[0039] A new type of inorganic-organic material synergistic quick-dividing biochemical ball, as shown in the figure, includes a filler 1, a hollowed-out net cover 2, and a hollowed-out lower net cover 3, and four barbs 4 are evenly spaced at the bottom of the net cover 2 , the top of the lower net cover 3 is provided with a snap-in slot 5 corresponding to the barb 4, the net cover 2 and the lower net cover 3 are detachably fastened together through the barb 4 and the snap-in slot 5, forming a hollow with a diameter of 200mm The spherical shell is equipped with composite filler 1, and the spherical shell is made of polyethylene material.

[0040] The preparation method of the novel inorganic-organic material synergistic rapid separation biochemical ball is as follows:

[0041] (1) The adsorption rate is 1.2%, and the density is 1.2g / cm 3 The volcanic rock with a wear rate of 0.24, a porosity of 43%, a compressive strength of 1080kgf, and a mechanical strength of 5.10MPa was gr...

Embodiment 3

[0047] A new type of inorganic-organic material synergistic quick-dividing biochemical ball, as shown in the figure, includes a filler 1, a hollowed-out net cover 2, and a hollowed-out lower net cover 3, and four barbs 4 are evenly spaced at the bottom of the net cover 2 , the top of the lower net cover 3 is provided with a snap-in groove 5 corresponding to the barb 4, and the net cover 2 and the lower net cover 3 are detachably fastened together through the barb 4 and the snap-in slot 5 to form a hollow with a diameter of 300mm The spherical shell is equipped with composite filler 1, and the spherical shell is made of polyethylene material.

[0048] The preparation method of the novel inorganic-organic material synergistic rapid separation biochemical ball is as follows:

[0049] (1) The adsorption rate is 1.3%, and the density is 1.4g / cm 3 The volcanic rock with a wear rate of 0.23, a porosity of 48%, a compressive strength of 1100kgf, and a mechanical strength of 5.12MPa w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com